Anti-static and scratch-resistant automobile paint and preparation method thereof

An antistatic, automotive technology, applied in conductive coatings, coatings, polyurea/polyurethane coatings, etc., can solve problems such as weak scratch resistance, affecting the appearance of cars, and easy reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

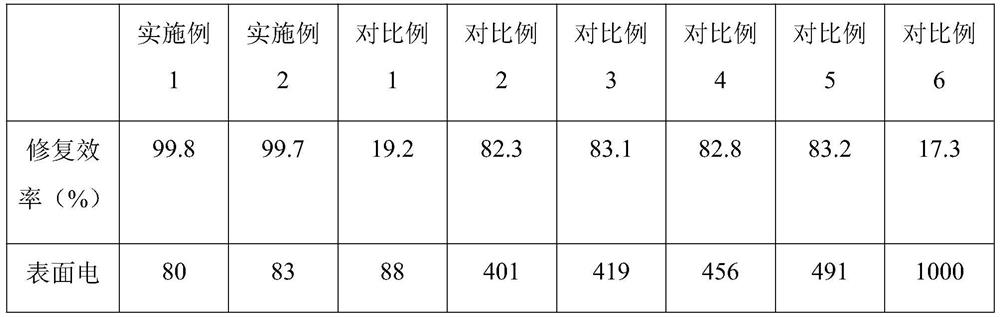

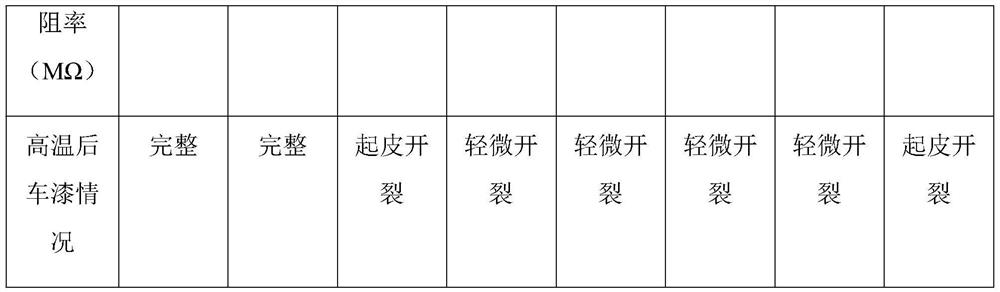

Examples

Embodiment 1

[0034] An antistatic anti-scratch automotive paint, mainly comprising: 60 parts of modified polyurethane, 10 parts of self-made filler, 1 part of polysorbate, 0.1 part of tributyl phosphate, 3 parts of distearate in parts by weight , 40 parts deionized water.

[0035] A kind of preparation method of antistatic anti-scratch automobile paint, described a kind of preparation method of antistatic anti-scratch automobile paint mainly comprises following preparation steps:

[0036] (1) Hydroxyphenylketoglyoxal is dissolved in absolute ethanol with 5 times the quality of hydroxyphenylketoglyoxal, heated to 80°C, and potassium hydroxide / ethanol solution with 3 times the quality of hydroxyphenylketoglyoxal is added dropwise at a speed of 2mL / min, The mass ratio of potassium hydroxide and absolute ethanol in the potassium hydroxide / ethanol solution is 1:4.70, add bromochlorochalcone with 2 times the mass of hydroxypropiophenone aldehyde, react for 3 hours, and rotate at 200rpm and 80°C ...

Embodiment 2

[0049] An antistatic anti-scratch automotive paint, mainly comprising: 80 parts of modified polyurethane, 20 parts of self-made filler, 4 parts of polysorbate, 0.5 part of tributyl phosphate, 6 parts of distearate in parts by weight , 50 parts deionized water.

[0050] A kind of preparation method of antistatic anti-scratch automobile paint, described a kind of preparation method of antistatic anti-scratch automobile paint mainly comprises following preparation steps:

[0051] (1) Hydroxyphenylketoglyoxal is dissolved in absolute ethanol with 6 times the quality of hydroxyphenylketoglyoxal, heated to 85°C, and potassium hydroxide / ethanol solution with 4 times the quality of hydroxyphenylketoglyoxal is added dropwise at a speed of 4mL / min, The mass ratio of potassium hydroxide and absolute ethanol in the potassium hydroxide / ethanol solution is 1:4.70, add bromochlorochalcone with 3 times the mass of hydroxypropiophenone aldehyde, react for 5 hours, and rotate at 300rpm and 80°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com