Anti-radiation fabric and treatment method thereof

A processing method and anti-radiation technology, which is applied in the field of clothing fabrics, can solve the problems of general anti-radiation performance and low softness, and achieve the effects of improved anti-radiation performance, high comfort, and improved anti-radiation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

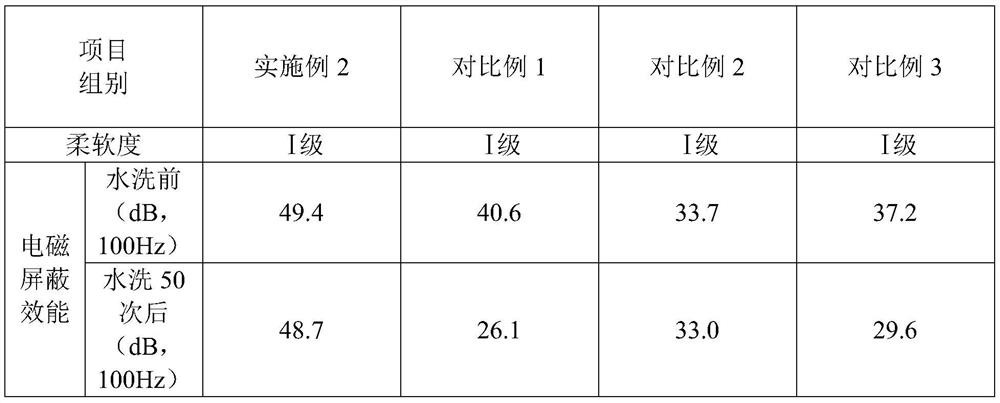

Examples

Embodiment 1

[0024] A processing method for a radiation-proof fabric, the steps comprising:

[0025] Step 1: Take a cotton fiber with a diameter of 0.01mm, add the cotton fiber to deionized water containing 5g / L polyamide wax, control the weight bath ratio to 1:10, and the temperature is 30°C, perform softening treatment for 20 minutes, and finally dehydrate drying to obtain the modified cotton fiber for subsequent use;

[0026] Step 2: take a copper wire fiber with a diameter of 0.015 mm, anneal it at 480° C. for 30 minutes, and then evenly load radiation-proof synergistic particles on the surface of the annealed copper wire fiber to obtain a modified copper wire fiber for use;

[0027] Among them, the specific operation of loading the anti-radiation synergistic particles is as follows: use 0.55mol / L sodium hydroxide solution to etch the surface of the copper wire fiber, the temperature of the etching treatment is 40°C, and the time is 100min, so that the copper wire A three-dimensional ...

Embodiment 2

[0030] A processing method for a radiation-proof fabric, the steps comprising:

[0031] Step 1: Take a cotton fiber with a diameter of 0.03mm, add the cotton fiber to deionized water containing 15g / L KGS-9068, control the weight bath ratio to 1:12, and the temperature is 40°C, perform softening treatment for 25 minutes, and finally dehydrate drying to obtain the modified cotton fiber for subsequent use;

[0032] Step 2: take a stainless steel wire fiber with a diameter of 0.02mm, anneal it at 950°C for 45 minutes, and then uniformly load radiation protection synergistic particles on the surface of the annealed stainless steel wire fiber to obtain a modified stainless steel wire fiber for use;

[0033] Among them, the specific operation of loading the anti-radiation synergistic particles is: use 3mol / L sodium hydroxide solution to etch the surface of the stainless steel wire fiber, the temperature of the etching treatment is 35°C, and the time is 65min, so that the stainless st...

Embodiment 3

[0036] A processing method for a radiation-proof fabric, the steps comprising:

[0037] Step 1: Take a cotton fiber with a diameter of 0.05mm, add the cotton fiber to deionized water containing 20g / L silicone oil, control the weight bath ratio to 1:15, and the temperature is 50°C, perform a softening treatment for 30 minutes, and finally dehydrate and dry Dry, obtain the modified cotton fiber for subsequent use;

[0038] Step 2: Take an aluminum alloy wire fiber with a diameter of 0.025 mm, anneal it at 420° C. for 60 minutes, and then uniformly load radiation protection synergistic particles on the surface of the annealed aluminum alloy wire fiber to obtain a modified aluminum alloy wire fiber for use;

[0039] Among them, the specific operation of loading the anti-radiation synergistic particles is as follows: use 5mol / L potassium hydroxide solution to etch the surface of the aluminum alloy wire fiber, the temperature of the etching treatment is 40°C, and the time is 100min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com