Preparation method of layered graphite flexible current collector

A flexible current collector and graphite technology, which is applied in the manufacture of hybrid/electric double layer capacitors and hybrid capacitor collectors, can solve the problems of reducing the electrochemical performance of devices and affecting the conductivity of current collectors, so as to improve electrochemical performance and increase Effect of contact area and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Paste the transparent tape on the graphite paper, and peel off the tape at a speed of 0.5cm / s. Then the graphite paper stripped by the tape was placed in water, and ultrasonically treated with 100W power for 120s. After washing with deionized water and drying, the layered graphite flexible current collector can be obtained.

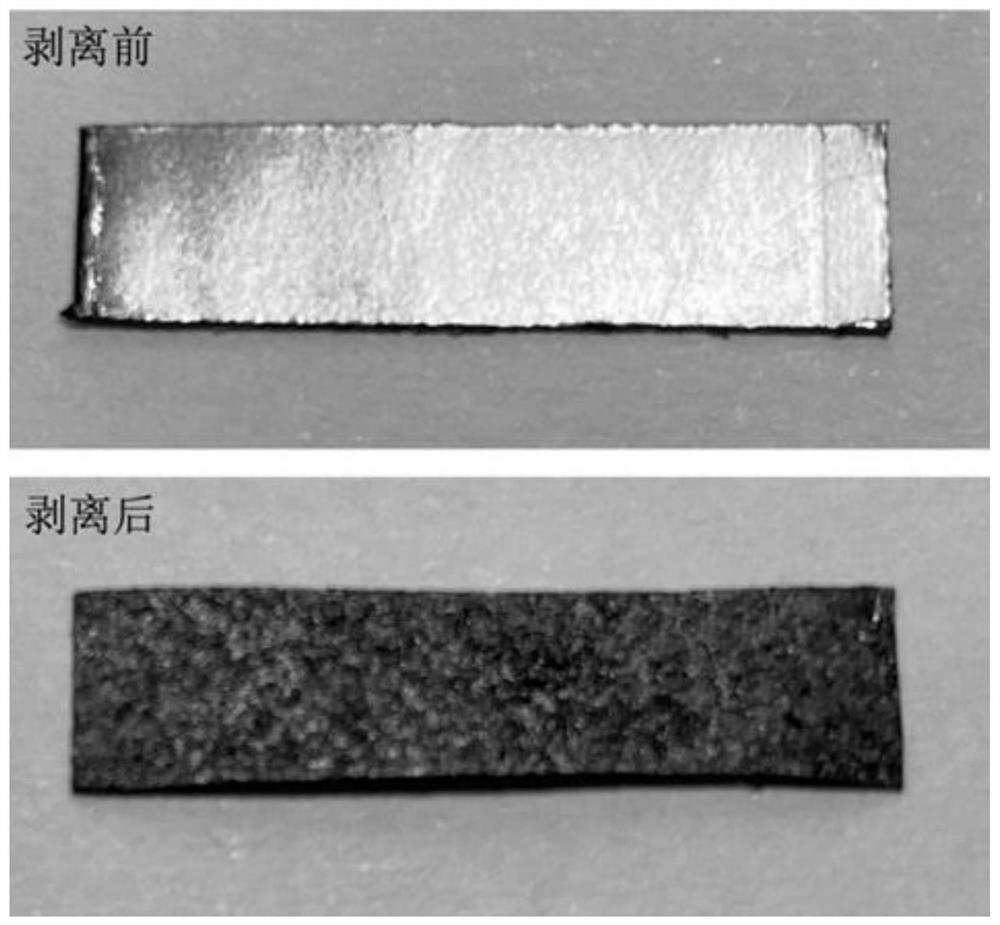

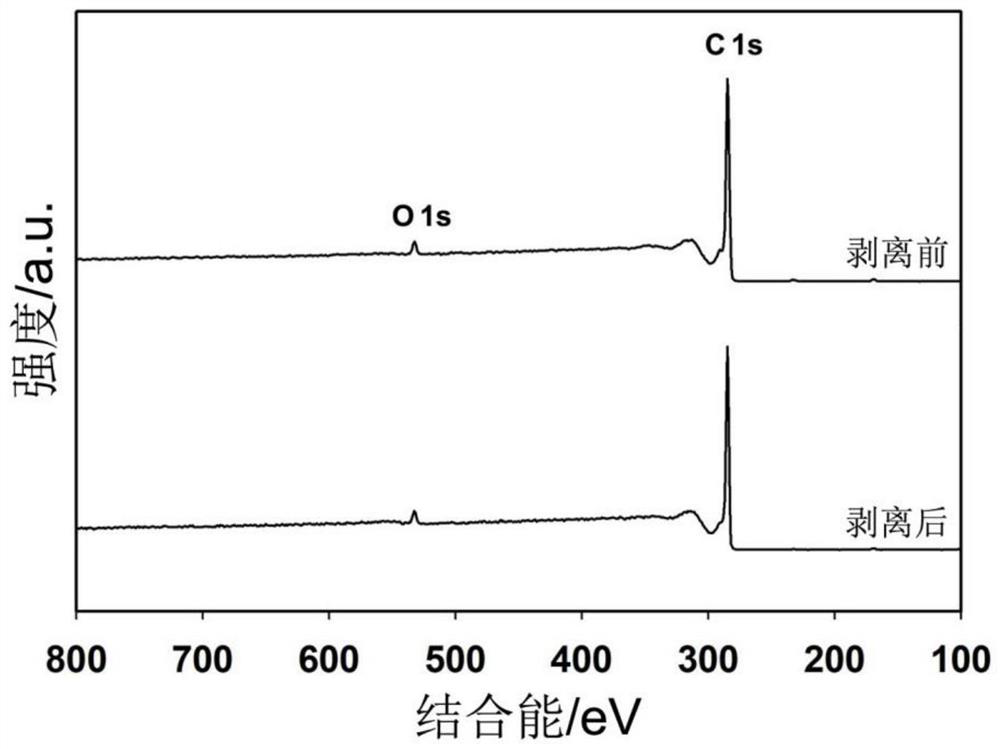

[0028] figure 1 The photos before and after mechanical peeling of the layered graphite flexible current collector prepared in this example are shown, and it can be seen that the graphite paper has changed from a smooth surface to a highly rough surface.

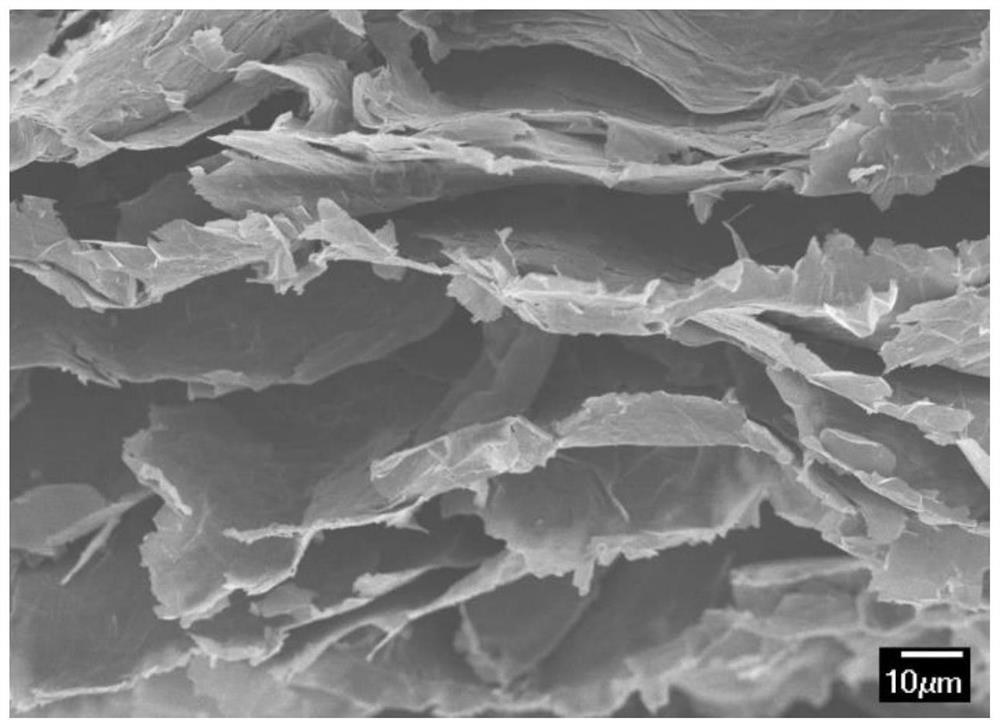

[0029] figure 2 The scanning electron microscope images of the layered graphite flexible current collector prepared in this example before and after mechanical stripping are shown. It can be seen from the figure that the prepared layered graphite flexible current collector exhibits the microstructure of three-dimensional layered graphite, which leads to figure 1 The rough surface observed in ....

Embodiment 2

[0033] Paste the masking tape on the graphite paper, and peel off the tape at a speed of 1.5cm / s. Subsequently, the graphite paper stripped by the tape was placed in ethanol, and ultrasonically treated with a power of 200W for 40s. After washing with deionized water and drying, the layered graphite flexible current collector can be obtained. The as-prepared current collector has a highly rough surface and a microstructure of three-dimensional layered graphite.

Embodiment 3

[0035] Paste the insulating tape on the graphite paper, and peel off the tape at a speed of 0.2cm / s. Then the graphite paper stripped by the tape was placed in ethanol, and ultrasonically treated with a power of 300W for 30s. After washing with deionized water and drying, the layered graphite flexible current collector can be obtained. The as-prepared current collector has a highly rough surface and a microstructure of three-dimensional layered graphite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com