Memristor based on doped two-dimensional halide perovskite thin film and preparation method of memristor

A halide perovskite, memristor technology, applied in electrical components and other directions, to achieve the effect of excellent transport characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

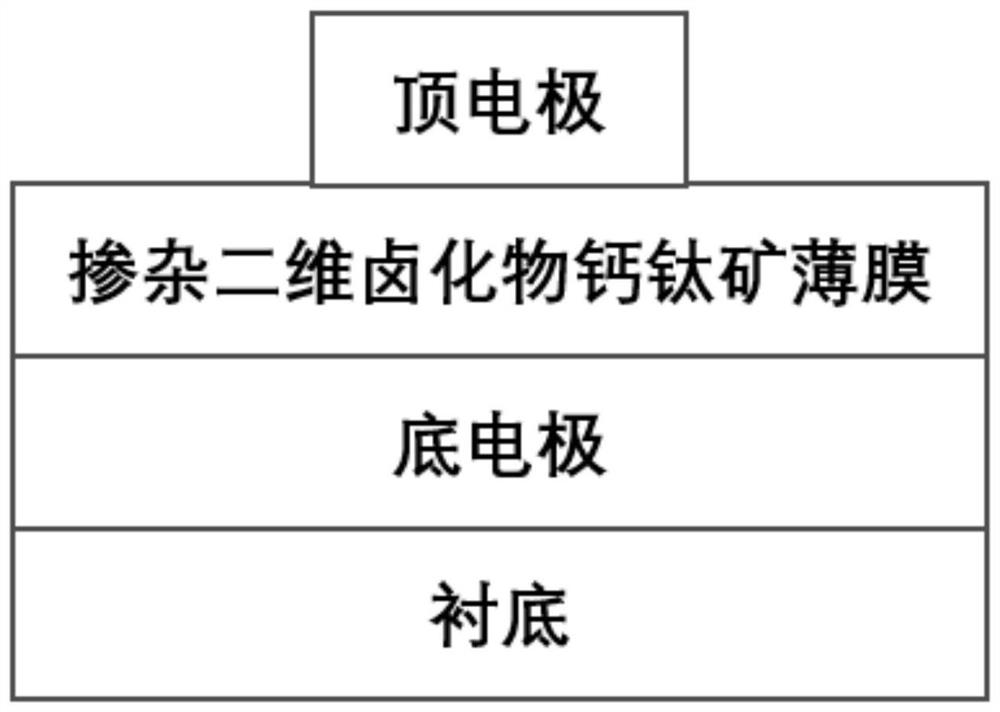

[0048] The present invention is based on a method for preparing a doped two-dimensional halide perovskite thin film memristor, comprising the following steps:

[0049] S1. Select conductive glass or silicon wafer as the substrate, and deposit a conductive film with a thickness of 80 to 200 nanometers on the substrate as the bottom electrode of the device by sputtering or deposition process;

[0050] S2. Mix the nanoparticles and the two-dimensional organic-inorganic halide perovskite according to the mass ratio of (1-50):100, dissolve them in excess dimethyl sulfoxide solution, and ultrasonically treat them in a water bath for 10-60 minutes , to obtain a precursor solution for depositing a resistive switchable thin film; the configured precursor solution is spin-coated on the substrate at a speed of 500-3000rpm, and the spin-coating time is 30-90s. In the last 5-15 seconds of spin-coating, chlorobenzene is added as Anti-solvent; then anneal at 100-200°C for 10-50 minutes in a ...

Embodiment 1

[0060] 1) Select conductive glass as the substrate, and deposit a conductive film with a thickness of 100 nm on the substrate as the bottom electrode of the device by using a sputtering process.

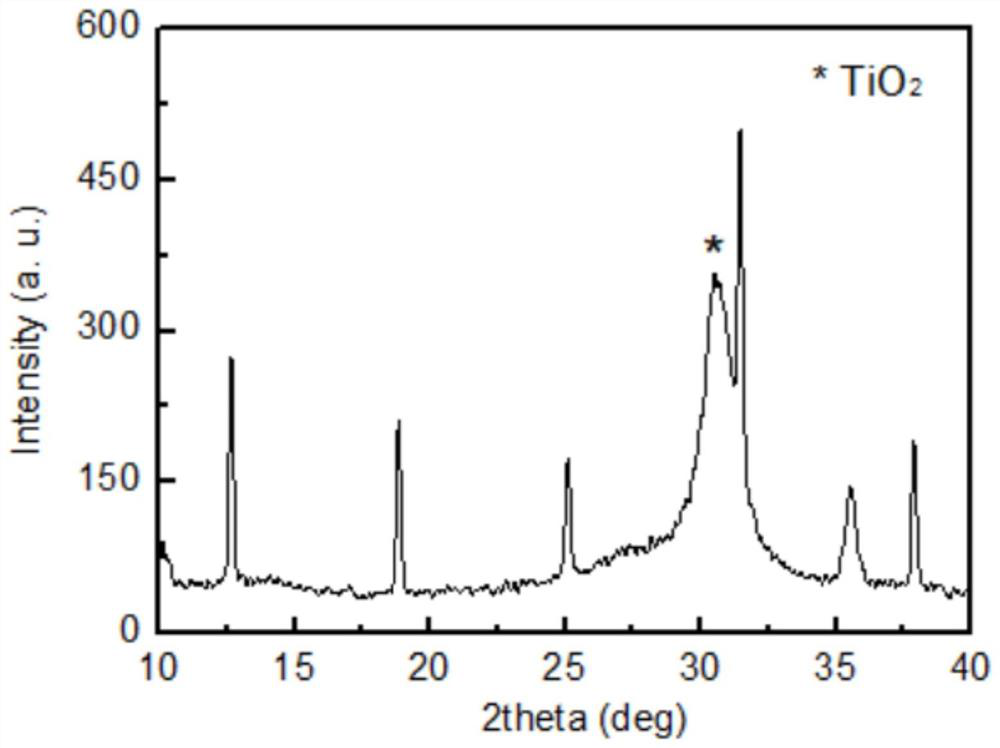

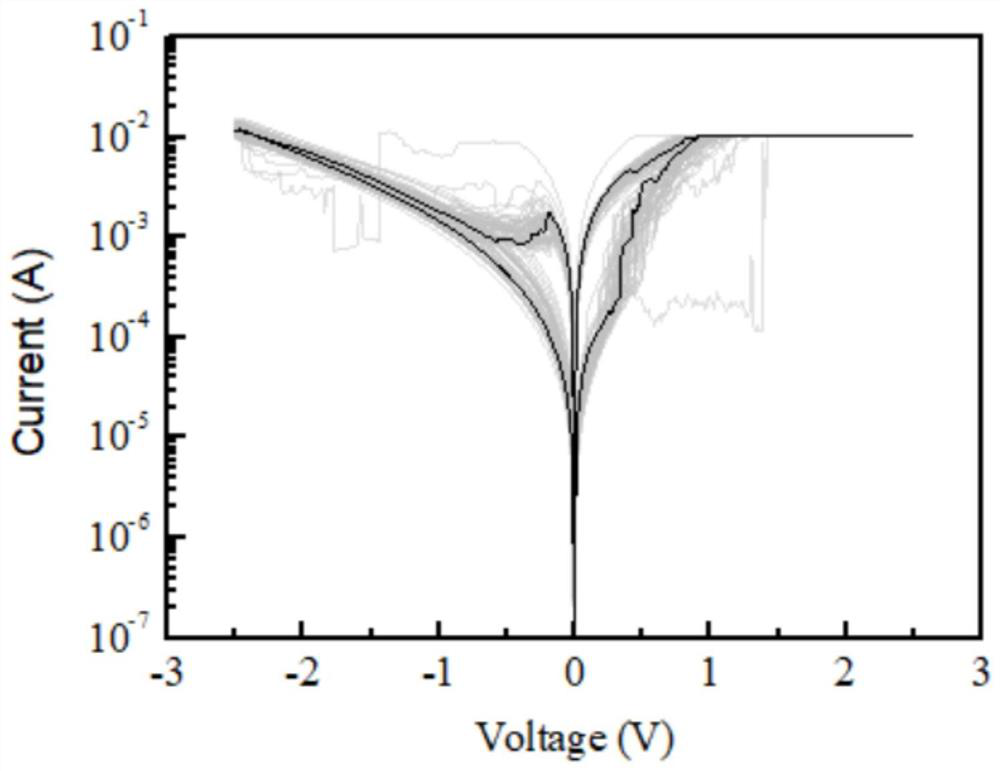

[0061] 2) TiO 2 Nanoparticles and two-dimensional organic-inorganic halide perovskite PEA 2 PbBr 4 Mixed together according to the mass ratio of 3:100, dissolved in excess dimethyl sulfoxide solution, and ultrasonically treated in a water bath for 20 minutes to obtain a precursor solution for depositing a resistive switching film; spin-coat the configured solution at a speed of 3000rpm on On the substrate, the spin-coating time is 60s. In the last 10s of spin-coating, chlorobenzene is added as an anti-solvent; then annealed at 120°C for 20 minutes in a high-purity argon environment, and TiO is obtained after natural cooling. 2 Nanoparticle-doped two-dimensional halide perovskite thin film as a memory layer.

[0062] 3) A circular mask with a diameter of 100 μm is used, and a metal...

Embodiment 2

[0069] 1) Select conductive glass as the substrate, and deposit a conductive film with a thickness of 100 nm on the substrate as the bottom electrode of the device by using a sputtering process.

[0070] 2) TiO 2 Nanoparticles and two-dimensional organic-inorganic halide perovskite PEA 2 PbBr 4 Mix together according to the mass ratio of 50:100, dissolve in excess dimethyl sulfoxide solution, and ultrasonically treat in a water bath for 20 minutes to obtain a precursor solution for depositing a resistive switching film; spin-coat the prepared solution at a speed of 3000rpm on On the substrate, the spin-coating time is 60s. In the last 10s of spin-coating, chlorobenzene is added as an anti-solvent; then annealed at 120°C for 20 minutes in a high-purity argon environment, and TiO is obtained after natural cooling. 2 Nanoparticle-doped two-dimensional halide perovskite thin film as a memory layer.

[0071] 3) Using a circular mask with a diameter of 100 μm, a metal aluminum fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com