Method for purifying pig-breeding wastewater by manganese metal self-loaded biochar

A self-loading, biochar technology, applied in chemical instruments and methods, animal husbandry wastewater treatment, special compound water treatment, etc., can solve problems such as difficulty in effluent quality, large actual consumption of chemical methods, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

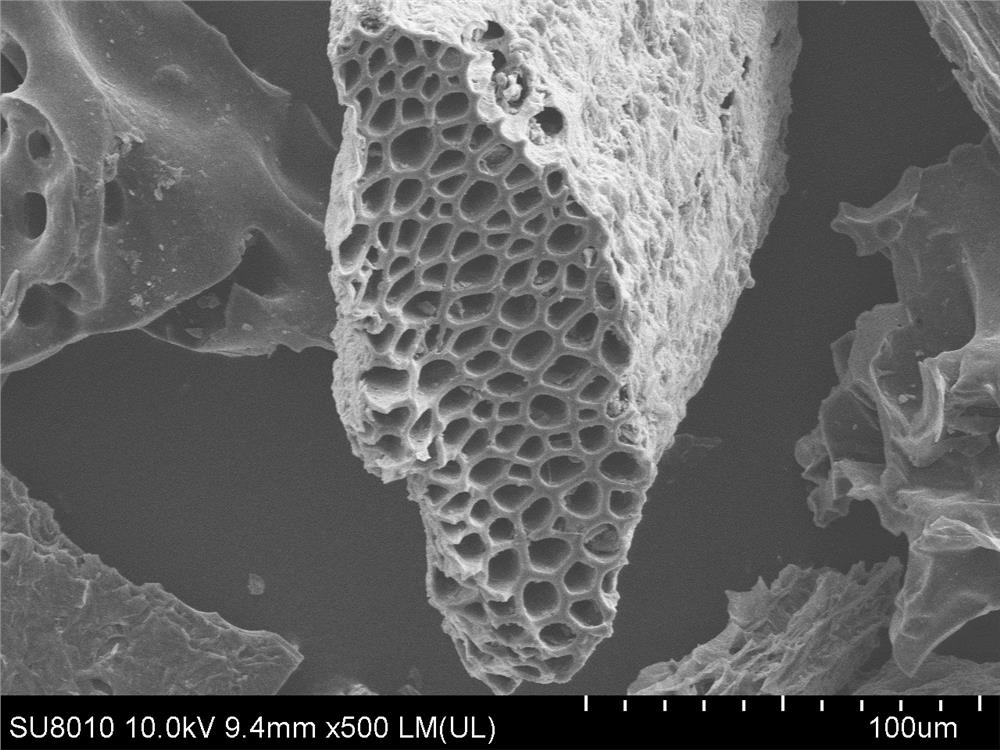

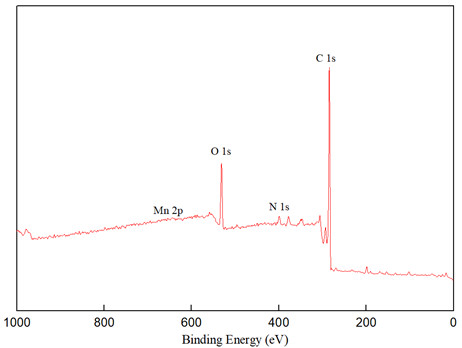

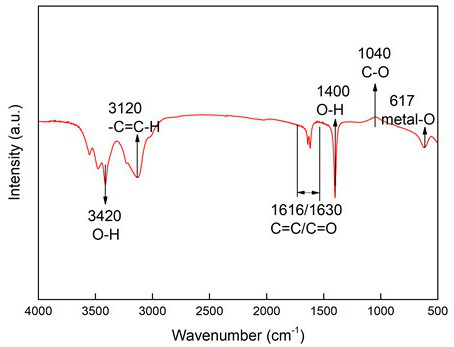

[0024] Example 1: A. Preparation of metal manganese self-supporting biochar: After harvesting the corn stalks collected from manganese-rich soil and growing for 30 days, crush them to 2 cm, dry them in an oven at 80°C for 12 hours, and put them into a nitrogen atmosphere tube type Furnace, set the heating rate at 5°C / min, and treat at 400°C for 2 hours; cool to room temperature, grind to 60 mesh to obtain metal manganese self-supporting biochar; B, pretreatment of pig manure, solid-liquid separation: The solid-liquid separation of suspended solids is realized through 140-mesh screen filtration and plate-and-frame pressure filtration, and the solid-liquid separation of insoluble impurities is realized by adding 0.01% polyacrylamide flocculant to the filtrate, and finally the pig raising wastewater after the solid matter is separated C, deployment of pig raising wastewater: add metal manganese self-loaded biochar to the pig raising wastewater after separating solid matter in a ra...

Embodiment 2

[0025] Example 2: A. Preparation of metal manganese self-supporting biochar: After harvesting the corn stalks collected from manganese-rich soil and growing for 30 days, crush them to 2 cm, dry them in an oven at 80°C for 12 hours, and put them into a nitrogen atmosphere tube type Furnace, set the heating rate at 5°C / min, and treat at 400°C for 2 hours; cool to room temperature, grind to 60 mesh to obtain metal manganese self-supporting biochar; B, pretreatment of pig manure, solid-liquid separation: The solid-liquid separation of suspended solids is realized through 140-mesh screen filtration and plate-and-frame pressure filtration, and the solid-liquid separation of insoluble impurities is realized by adding 0.01% polyacrylamide flocculant to the filtrate, and finally the pig raising wastewater after the solid matter is separated C, deployment of pig raising wastewater: add metal manganese self-loaded biochar to the pig raising wastewater after separating solid matter in a ra...

Embodiment 3

[0026]Example 3: A. Preparation of metal manganese self-supporting biochar: After harvesting the corn stalks collected from manganese-rich soil and growing for 30 days, crush them to 2 cm, dry them in an oven at 80°C for 12 hours, and put them into a nitrogen atmosphere tube type Furnace, set the heating rate at 5°C / min, and treat at 400°C for 2 hours; cool to room temperature, grind to 60 mesh to obtain metal manganese self-supporting biochar; B, pretreatment of pig manure, solid-liquid separation: The solid-liquid separation of suspended solids is realized through 140-mesh screen filtration and plate-and-frame pressure filtration, and the solid-liquid separation of insoluble impurities is realized by adding 0.01% polyacrylamide flocculant to the filtrate, and finally the pig raising wastewater after the solid matter is separated C, deployment of pig raising wastewater: add metal manganese self-supporting biochar to the pig raising wastewater after separating solid matter in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com