Preparation method of efficient powdery water reducing agent with siloxane structure

A technology of powdery water reducer and siloxane, which is applied in the field of preparation of high-efficiency powdery water reducer, can solve the defects of polycarboxylate water reducer concrete slump, viscosity, water reducing rate, cumbersome operation process, Affect the later strength and other issues, achieve good water reduction and slump performance, simplify the mixing process, and improve the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: Pour 200mL tetrahydrofuran into a 250mL narrow-mouth bottle, pour 20g of sodium hydroxide in flake form, and let it stand for 24 hours. Put 2g of sodium in a 250mL round bottom flask, pour about 150mL of tetrahydrofuran treated with NaOH, then add a few zeolite grains, heat and reflux for 30min, change to a distillation device after cooling, receive the distillate near 64~68℃, and store the product Reserve in a grinding bottle.

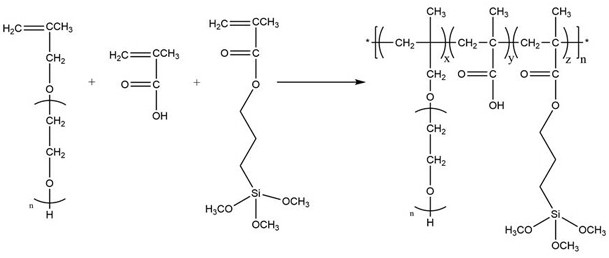

[0027] The second step: In the dried three-necked flask, add 40.0 mL of tetrahydrofuran obtained in the first step, and then add 1.2 g of methacrylic acid, 20.1 g of methallyl polyoxyethylene ether, 3-(trimethoxysilyl ) Propyl methacrylate 3.4g, 4,4-azobis(4-cyanovaleric acid) 0.13g, stirred vigorously, and protected by nitrogen gas, reacted at 70°C for 5 hours, continued to protect by nitrogen gas and cooled After 24 hours.

[0028] Step 3: Rotate evaporate the reacted mixed solution at 50°C to obtain a colorless viscous liquid.

[...

Embodiment 2

[0032] Step 1: Pour 150mL tetrahydrofuran into a 250mL narrow-mouth bottle, pour 15g of sodium hydroxide in flake form, and let it stand for 24 hours. Put 1.5g of sodium in a 250mL round bottom flask, pour about 160mL of tetrahydrofuran treated with NaOH, then add a few zeolite grains, heat and reflux for 30min, change to a distillation device after cooling, and receive the distillate near 64~68℃, the product Store in a grinding bottle for later use.

[0033] The second step: In the dried three-necked flask, add 35.0 mL of tetrahydrofuran obtained in the first step, and then add 2 g of methacrylic acid, 18.9 g of methallyl polyoxyethylene ether, 3-(trimethoxysilyl ) Propyl methacrylate 3.6g, 4,4-azobis(4-cyanovaleric acid) 0.25g, stirred vigorously, and protected by nitrogen gas, reacted at 70°C for 5 hours, continued to protect by nitrogen gas and cooled After 24 hours.

[0034] Step 3: Rotate evaporate the reacted mixed solution at 50°C to obtain a colorless viscous liquid...

Embodiment 3

[0038] Step 1: Pour 170mL of tetrahydrofuran into a 250mL narrow-mouth bottle, pour 23g of sodium hydroxide into flakes, and let it stand for 24 hours. Put 2.2g of sodium in a 250mL round bottom flask, pour about 150mL of tetrahydrofuran treated with NaOH, then add a few zeolite grains, heat and reflux for 30min, change to a distillation device after cooling, and receive the distillate near 64~68℃, the product Store in a grinding bottle for later use.

[0039] The second step: In the dried three-necked flask, add 50.0 mL of tetrahydrofuran obtained in the first step, and then add 0.8 g of methacrylic acid, 16 g of methallyl polyoxyethylene ether, 3-(trimethoxysilyl) Propyl methacrylate 4g, 4,4-azobis(4-cyanovaleric acid) 0.35g, stirred vigorously, and protected by nitrogen, reacted at 70°C for 5 hours, continued to protect by nitrogen and cooled to 24 after h.

[0040] Step 3: Rotate evaporate the reacted mixed solution at 50°C to obtain a colorless viscous liquid.

[0041]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com