Preparation method of colorless polyisocyanate composition

A technology of polyisocyanate and diisocyanate, which is applied in the field of preparation of colorless polyisocyanate composition, can solve problems such as complex, poor chromaticity stability of the composition, unfavorable chromaticity stability of the product, etc., and achieves easy realization, simple operation and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] at 10m 3 Add 8m to the reactor 3 For the diisocyanate monomer, an inert gas (as shown in Table 1) was passed into the reactor at a certain flow rate, and the temperature of the system was raised to 70°C. Then add 12.6kg, 10% of 2-ethylhexanoic acid-N-(2-hydroxypropyl)-N,N,N-trimethylammonium salt in isooctyl alcohol (about 150ppm relative to the diisocyanate monomer ), control the reaction temperature at 70° C.; detect the reaction process by measuring the NCO content of the reaction solution, and when the reaction conversion rate reaches 41%, add 1.56 kg of dibutyl phosphate (about 185 ppm relative to the diisocyanate monomer) to terminate the reaction. Next, use a thin film evaporator to distill twice under the conditions of 150° C. and 30 Pa to obtain a polyisocyanate composition with a diisocyanate monomer content of less than 0.2%.

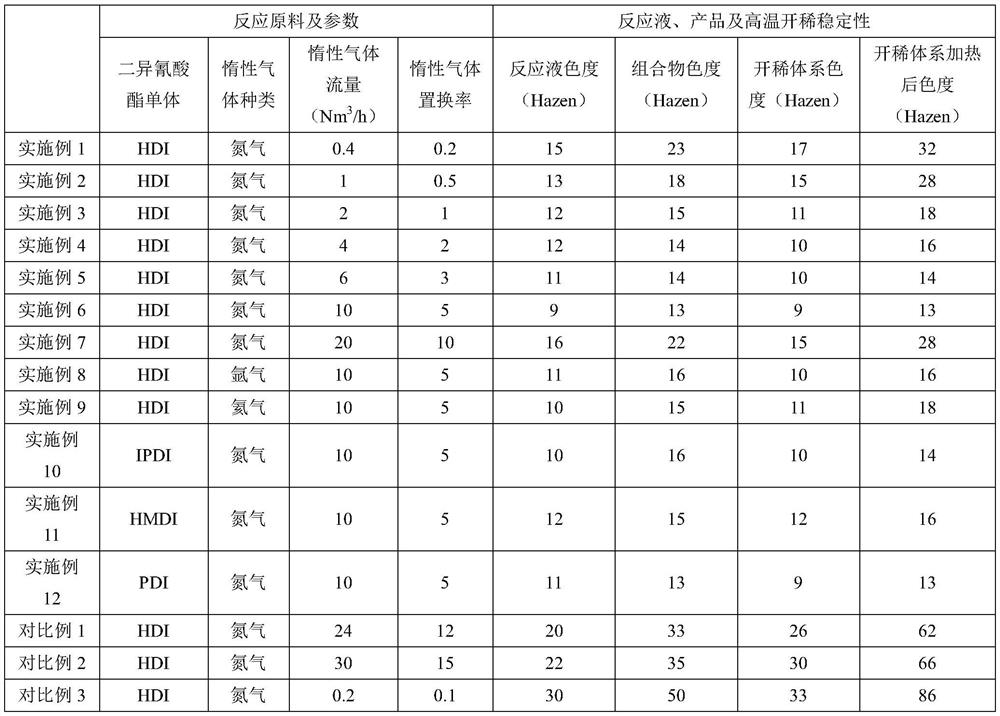

Embodiment 2-12 and comparative example 1-3

[0053] Referring to the method substantially the same as Example 1, Examples 2-12 and Comparative Examples 1-3 were prepared to prepare different polyisocyanate compositions, the only difference being that the reaction raw materials and parameters were adjusted as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com