Packaging structure and measuring conduit

A technology for packaging structures and measuring catheters, applied in catheters, cardiac catheters, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

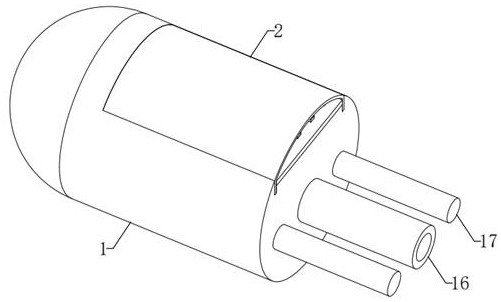

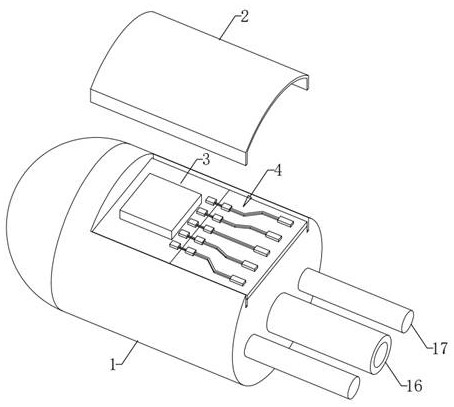

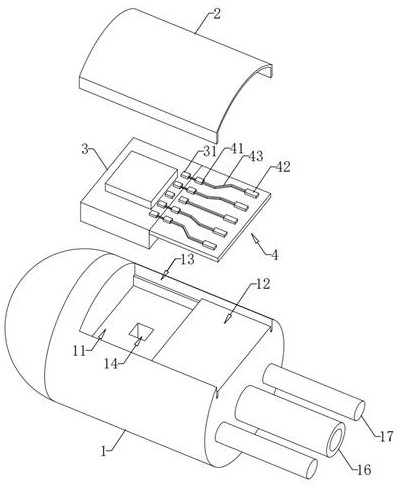

[0042] Such as figure 1 , figure 2As shown, a package structure of this embodiment includes: a base 1 with a receiving groove, a cover plate 2 for covering the opening of the receiving groove, a pressure sensor 3 embedded in the bottom of the receiving groove, and a welding wire plate 4. The base 1 and the cover plate 2 can be made of biocompatible materials such as stainless steel, titanium alloy, or polytetrafluoroethylene by injection molding or machining. Both the base 1 and the cover 2 are made of rigid materials, so the external stress will not be transmitted to the sensing surface of the sensor. At the same time, because the base 1 and the cover 2 also improve the sealing of the overall package, the sensor Measurement reliability.

[0043] Such as image 3 As shown, the base 1 is a cylindrical structure whose two ends are respectively a spherical end and a plane end, and the receiving groove communicates with the plane end of the base 1 . A third embedding groove ...

Embodiment 2

[0057] Such as image 3 , Figure 4 As shown, a connecting pipe 16 connected to a through hole 15 and two connecting rods 17 are arranged on the end face of the plane end of the base 1 , and the two connecting rods 17 are symmetrically distributed on both sides of the connecting pipe 16 . The connecting pipe 16 and the connecting rod 17 can be fixedly connected to the base 1 , or integrally formed with the base 1 . The connecting rod 17 is a round rod, and the axial directions of the connecting pipe 16 and the connecting rod 17 are parallel to the axial direction of the base 1 .

[0058] Such as Figure 4 , Figure 5 As shown, a measuring catheter in this embodiment includes: a base 1 , a catheter body 6 connected to the base 1 , and an enameled wire 5 connected between the base 1 and the catheter body 6 . The enameled wire 5 can use conductors and insulation, such as copper, aluminum and polyester, etc., and is made by setting out, annealing, painting, baking, cooling, lu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com