Composite material, electroluminescent diode and display device

A technology of composite materials and display devices, which is applied in the direction of circuits, electrical components, and electric solid devices, and can solve problems such as difficult design of driving circuits and difficulty in coordination and unification of driving circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

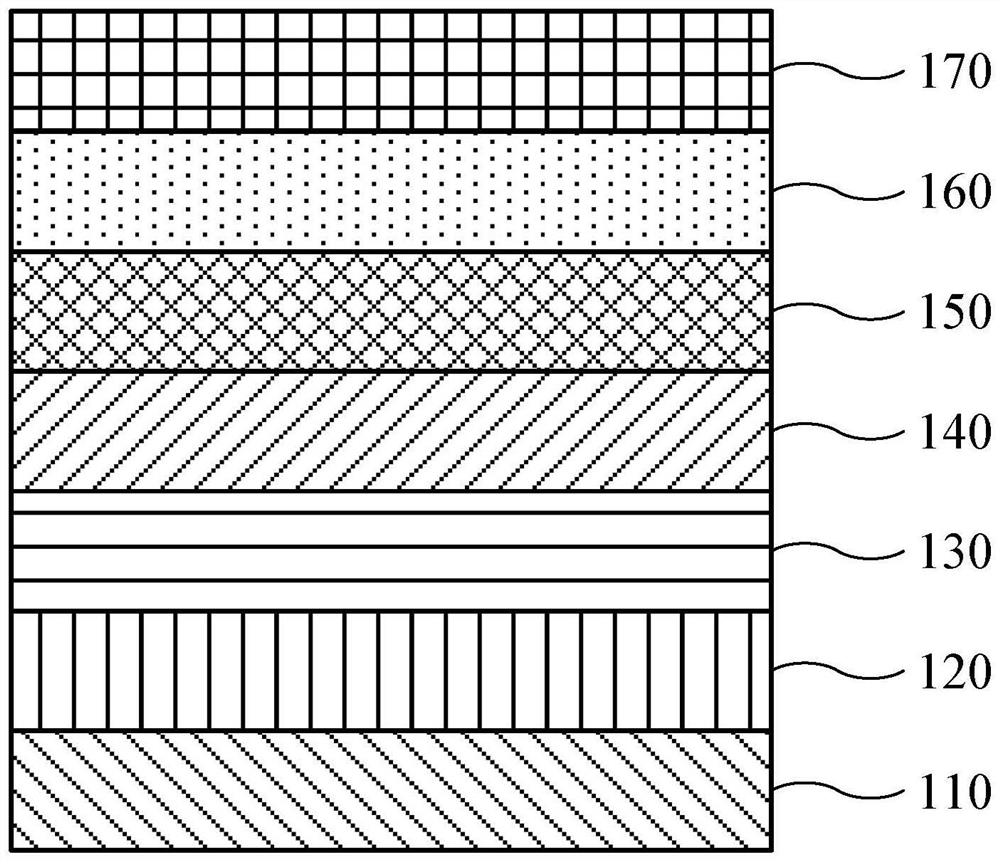

[0059] On the other hand, the present invention also provides a method for preparing an electroluminescent diode, which includes the following steps.

[0060] Step S1, preparing an anode on the substrate.

[0061] In a specific example, the material of the anode can be selected from silver, magnesium-silver alloy, gold, indium zinc oxide conductive film or indium tin oxide conductive film. The thickness of the anode 120 can be 20nm-100nm, for example, the thickness of the anode 120 is 20nm, 30nm, 40nm, 50nm, 60nm, 70nm, 80nm, 90nm, 100nm, or a range between the above thicknesses.

[0062] In a specific example, the substrate and the anode can be an integrated conductive glass, for example, glass is used as the substrate, and an indium tin oxide conductive film is used as the anode.

[0063] Step S2, depositing a hole injection layer on the anode.

[0064] In a specific example, the material of the hole injection layer is selected from materials with hole injection capability...

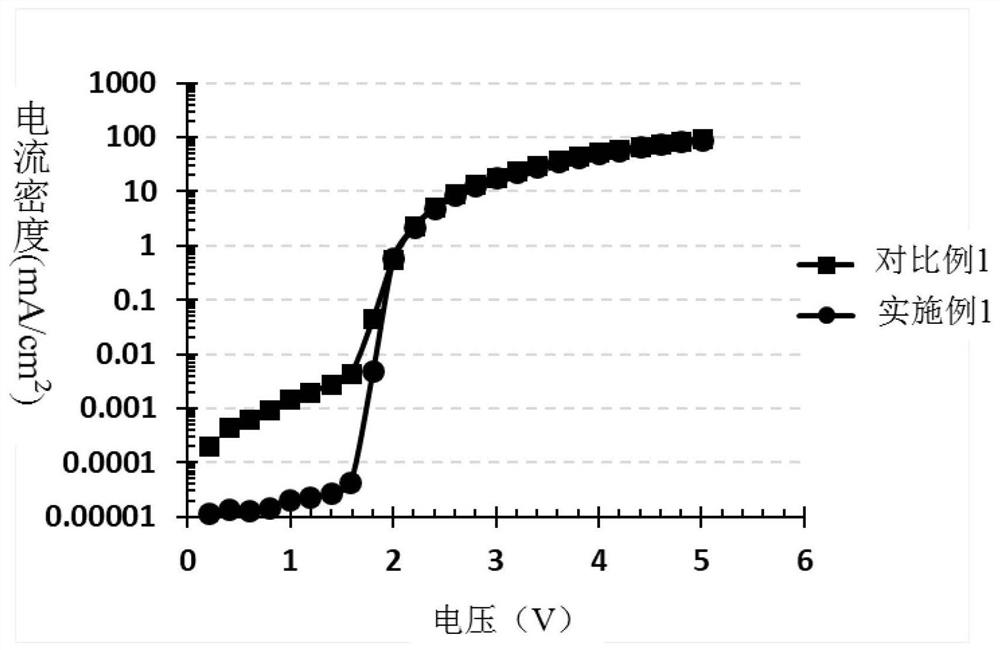

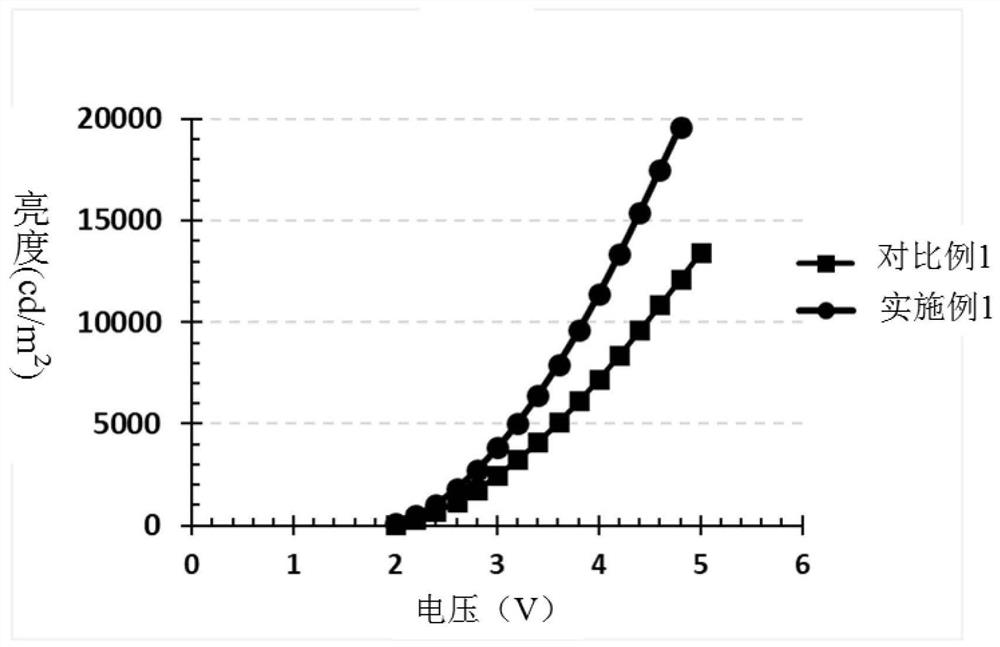

Embodiment 1

[0094] (1) Using transparent conductive film ITO as the anode, the thickness is 50nm;

[0095] (2) Deposit PEDOT by solution method on the anode: PSS is used as a hole injection layer with a thickness of 40nm;

[0096] (3) Utilizing solution method to deposit TFB on the hole injection layer as the hole transport layer, the thickness is 30nm;

[0097] (4) Deposit CdSe / ZnSe as a quantum dot luminescent layer on the hole transport layer by solution method, with a thickness of 15nm;

[0098] (5) Simultaneous deposition of SnO on the quantum dot light-emitting layer by solution method 2 Nanoparticles and HAT-CN as electron transport layer with a thickness of 50nm, in which HAT-CN and SnO 2 The mass ratio of 0.1:100;

[0099] (6) Depositing Ag as a cathode on the electron transport layer by evaporation method, with a thickness of 120 nm.

Embodiment 2

[0101] (1) Using transparent conductive film ITO as the anode, the thickness is 50nm;

[0102] (2) Deposit PEDOT by solution method on the anode: PSS is used as a hole injection layer with a thickness of 40nm;

[0103] (3) Utilizing solution method to deposit TFB on the hole injection layer as the hole transport layer, the thickness is 30nm;

[0104] (4) Deposit CdSe / ZnSe as a quantum dot luminescent layer on the hole transport layer by solution method, with a thickness of 15nm;

[0105] (5) Simultaneous deposition of SnO on the quantum dot light-emitting layer by solution method 2 Nanoparticles and HAT-CN as electron transport layer with a thickness of 50nm, in which HAT-CN and SnO 2 The mass ratio of 0.07:100;

[0106] (6) Depositing Ag as a cathode on the electron transport layer by evaporation method, with a thickness of 120 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com