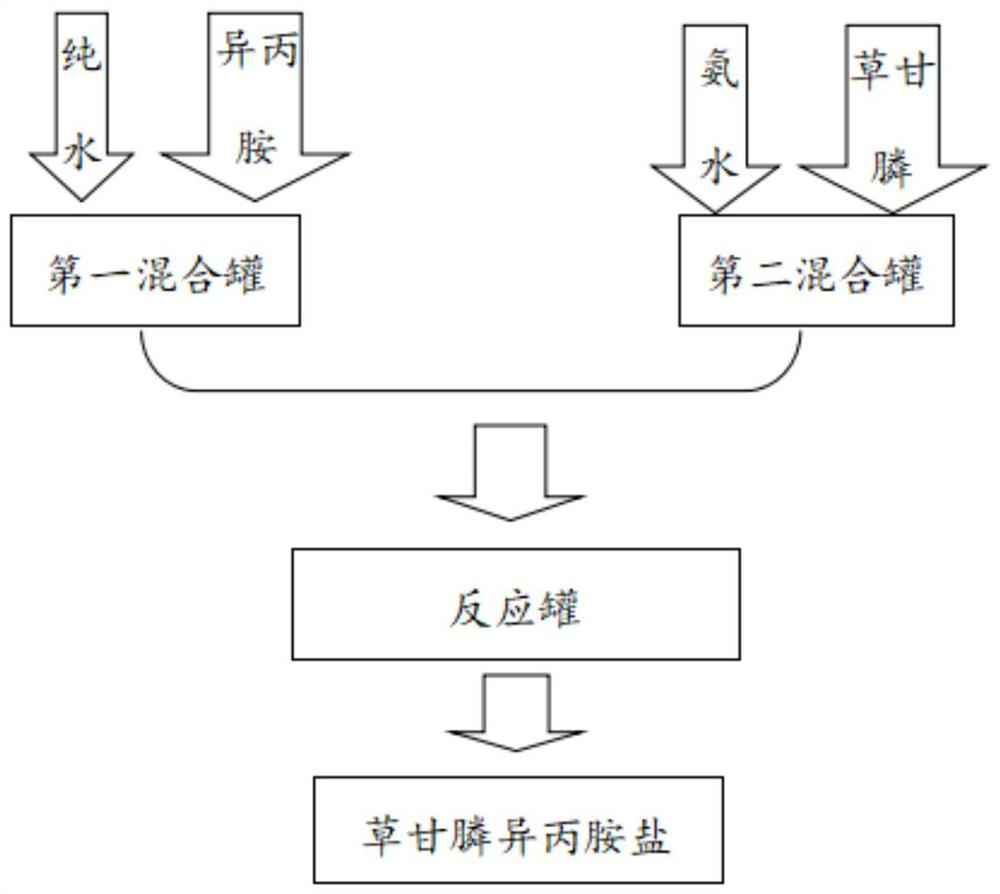

Production process for continuously producing glyphosate isopropylamine salt

A glyphosate isopropylamine salt and production process technology, which is applied in the field of continuous production of glyphosate isopropylamine salt, can solve problems such as explosion, low labor intensity, and easy combustion, so as to improve the safety factor and ensure continuous production. Production and the effect of reducing the risk of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

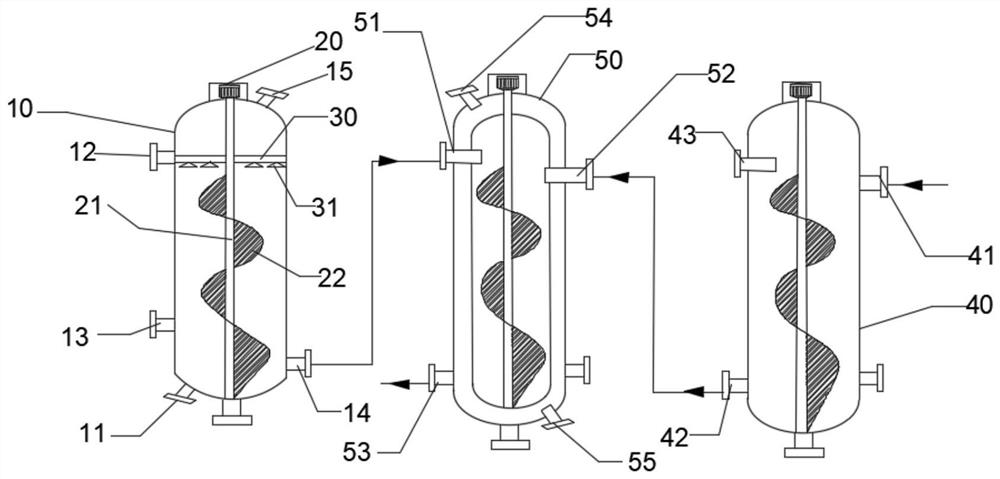

[0039] A production technique for continuous production of glyphosate isopropylamine salt, comprising the steps of:

[0040] Step 1. Replace the air in the first mixing tank 10 with nitrogen for 2 times, turn on the rotating motor 20, control the flow ratio of the inlet 12 of isopropylamine and the inlet 13 of pure water to 4:1, add isopropylamine and pure water, and stir , to obtain isopropylamine aqueous solution;

[0041] Step 2, turn on the rotating motor 20, and at 28° C., add glyphosate and ammonia water with a mass fraction of 28% into the second mixing tank 40 through the glyphosate inlet 41 and the ammonia water inlet 43 to control the flow rate ratio of 1:2, Stir until the pH of the glyphosate ammonia solution at the outlet of the second mixing tank 40 is 6.4;

[0042] Step 3, turn on the rotary motor 20, and at 26°C, control the flow rate ratio of 2.6:2 through the isopropylamine aqueous solution inlet 51 and the glyphosate ammonia solution inlet 52, and add the is...

Embodiment 2

[0044] On the basis of Embodiment 1, the rotating electrical machine 20 is kept running normally, the condensed water continues to flow back, and the following operations are performed:

[0045] Step 1, through the isopropylamine inlet 12 and the pure water inlet 13, control the incoming flow ratio to be 4.5:1, add isopropylamine and pure water, and stir to obtain an aqueous solution of isopropylamine;

[0046] Step 2, through the glyphosate inlet 41 and the ammonia water inlet 43, control the inlet flow ratio to be 1.5:3.2, add glyphosate and ammonia water with a mass fraction of 28% in the second mixing tank 40, and stir until the grass at the outlet of the second mixing tank 40 The pH of the ammonia solution of glyphosate is 6.7;

[0047] Step 3: At 28°C, through the inlet 51 of the aqueous solution of isopropylamine and the inlet 52 of the aqueous solution of glyphosate ammonia, the flow ratio of the inlet is controlled to be 2.7:2.2, and the aqueous solution of isopropyla...

Embodiment 3

[0049] On the basis of Embodiment 2, the rotating electrical machine 20 is kept running normally, the condensed water continues to flow back, and the following operations are performed:

[0050] Step 1, through the isopropylamine inlet 12 and the pure water inlet 13, control the incoming flow ratio to be 5:1, add isopropylamine and pure water, and stir to obtain an aqueous solution of isopropylamine;

[0051] Step 2, through the glyphosate inlet 41 and the ammonia water inlet 43, control the flow rate ratio of 2.3:4, add glyphosate and ammonia water with a mass fraction of 28% in the second mixing tank 40, stir until the second mixing tank 40 exits the grass The pH of the ammonia solution of glyphosate is 6.5;

[0052] Step 3: At 28°C, through the inlet 51 of the aqueous solution of isopropylamine and the inlet 52 of the aqueous solution of glyphosate ammonia, the ratio of the incoming flow is controlled to be 3:2.5. Add the aqueous solution of isopropylamine and the aqueous s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com