Zinc phytate@zeolite imidazate skeleton-8/molybdenum disulfide nanocomposite and preparation method and application thereof

A nano-composite material, molybdenum disulfide technology, applied in anti-corrosion coatings, coatings and other directions, can solve the problem of limited improvement of anti-corrosion performance of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

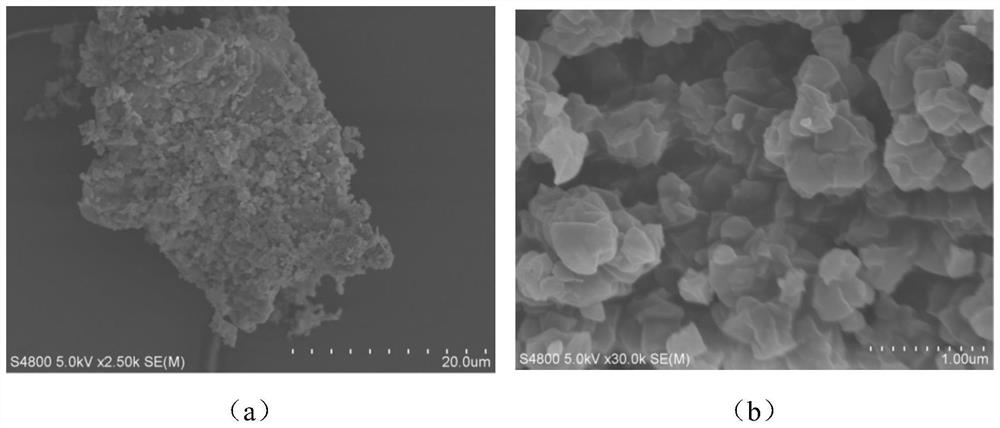

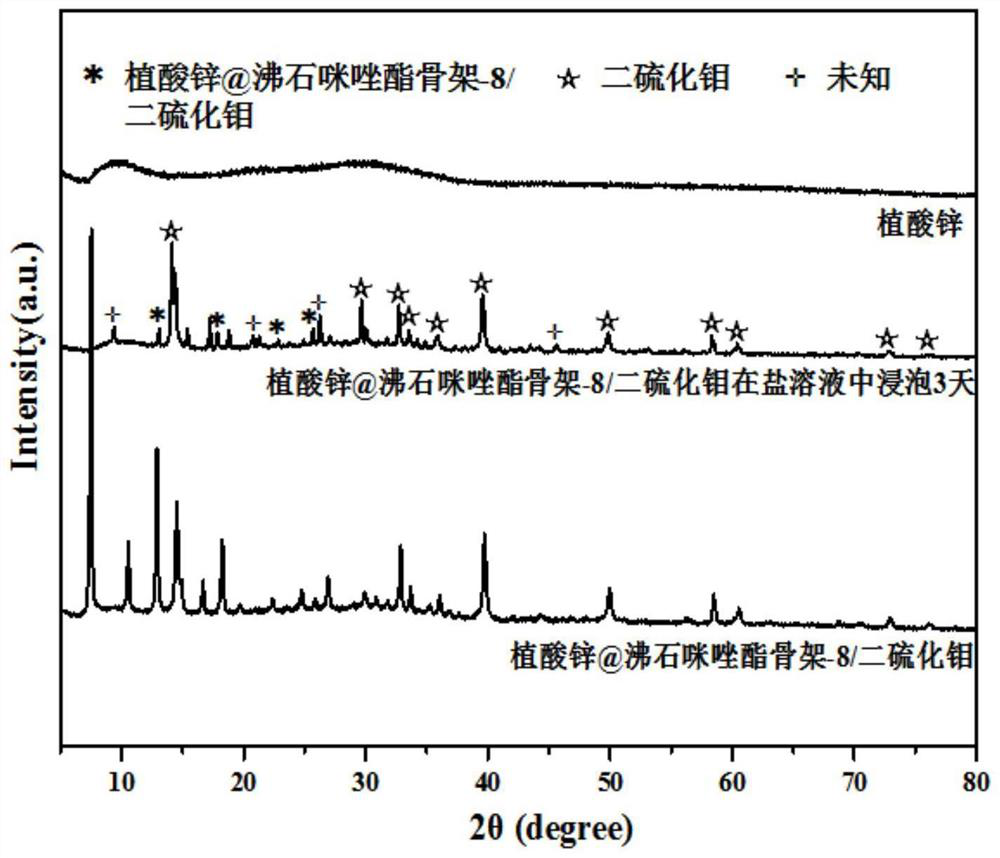

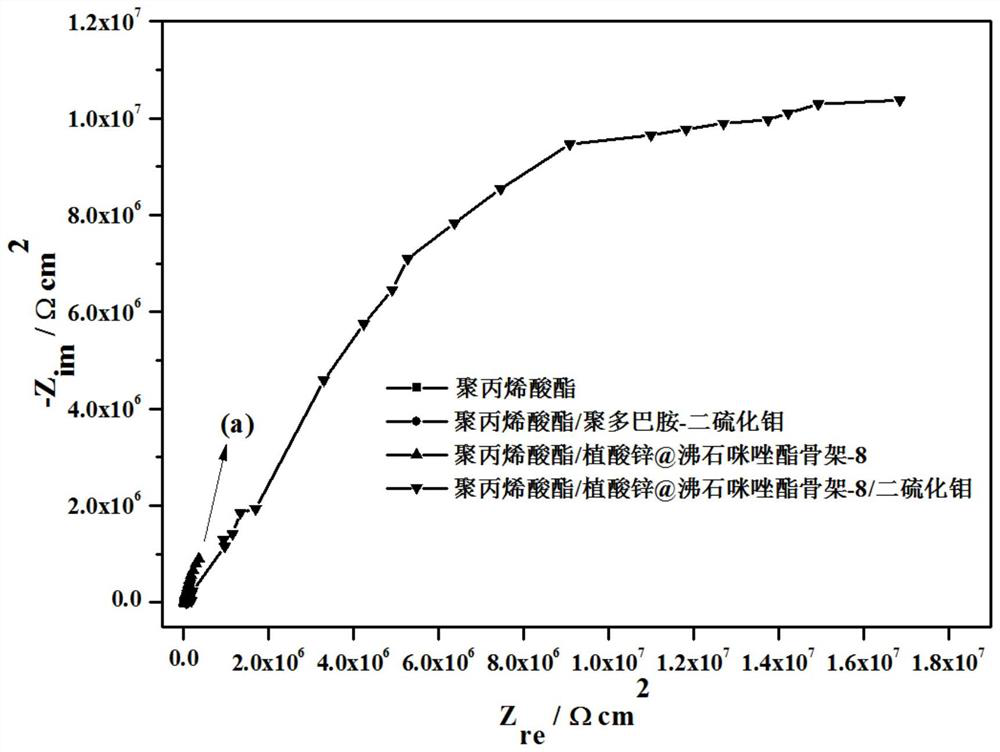

[0037] A preparation method of zinc phytic acid@zeolite imidazolate framework-8 / molybdenum disulfide nanocomposite material, comprising the following steps:

[0038] (1) Evenly disperse 0.5 g of molybdenum disulfide in a mixed solution of 50 mL of deionized water and absolute ethanol, and use an ultrasonic cell pulverizer to ultrasonically peel it for 6 h. After the sonication, centrifuge at 1500r / min, and collect the upper suspension. Then, the upper layer suspension was rotary evaporated at 40°C and freeze-dried to obtain few-layer molybdenum disulfide.

[0039] (2) ultrasonically disperse 0.06g of few-layer molybdenum disulfide in 10g of absolute ethanol for 0.5h, add 20g of Tris-buffer solution and then ultrasonically treat for 0.5h, then add 0.02g of dopamine hydrochloride, stir magnetically at room temperature for 12h, and finally, The product was collected by centrifugation, washed three times with ethanol, and dried in vacuum at 50° C. for 6 hours to obtain polydopami...

Embodiment 2

[0046] A preparation method of zinc phytic acid@zeolite imidazolate framework-8 / molybdenum disulfide nanocomposite material, comprising the following steps:

[0047] (1) Evenly disperse 0.8 g of molybdenum disulfide in a mixed solution of 80 mL of deionized water and absolute ethanol, and use an ultrasonic cell pulverizer to ultrasonically peel it for 8 h. After the sonication, centrifuge at 1800r / min, and collect the upper suspension. Then, the upper layer suspension was rotary evaporated at 45°C and freeze-dried to obtain few-layer molybdenum disulfide.

[0048] (2) ultrasonically disperse 0.08g of few-layer molybdenum disulfide in 12g of absolute ethanol for 0.6h, add 25g of Tris-buffer solution and then ultrasonically treat for 0.6h, then add 0.04g of dopamine hydrochloride, stir magnetically at room temperature for 20h, and finally, The product was collected by centrifugation, washed three times with ethanol, and dried in vacuum at 55° C. for 8 hours to obtain polydopami...

Embodiment 3

[0055] A preparation method of zinc phytic acid@zeolite imidazolate framework-8 / molybdenum disulfide nanocomposite material, comprising the following steps:

[0056] (1) Evenly disperse 1.2 g of molybdenum disulfide in a mixed solution of 120 mL of deionized water and absolute ethanol, and use an ultrasonic cell pulverizer to ultrasonically peel it for 10 h. After the sonication, centrifuge at 2000r / min, and collect the upper suspension. Then, the upper layer suspension was rotary evaporated at 50°C and freeze-dried to obtain few-layer molybdenum disulfide.

[0057] (2) ultrasonically disperse 0.10 g of few-layer molybdenum disulfide in 16 g of absolute ethanol for 0.7 h, add 30 g of Tris-buffer solution and then ultrasonically treat it for 0.8 h, then add 0.06 g of dopamine hydrochloride, stir magnetically at room temperature for 24 h, and finally, The product was collected by centrifugation, washed four times with ethanol, and dried in vacuum at 60° C. for 10 h to obtain po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com