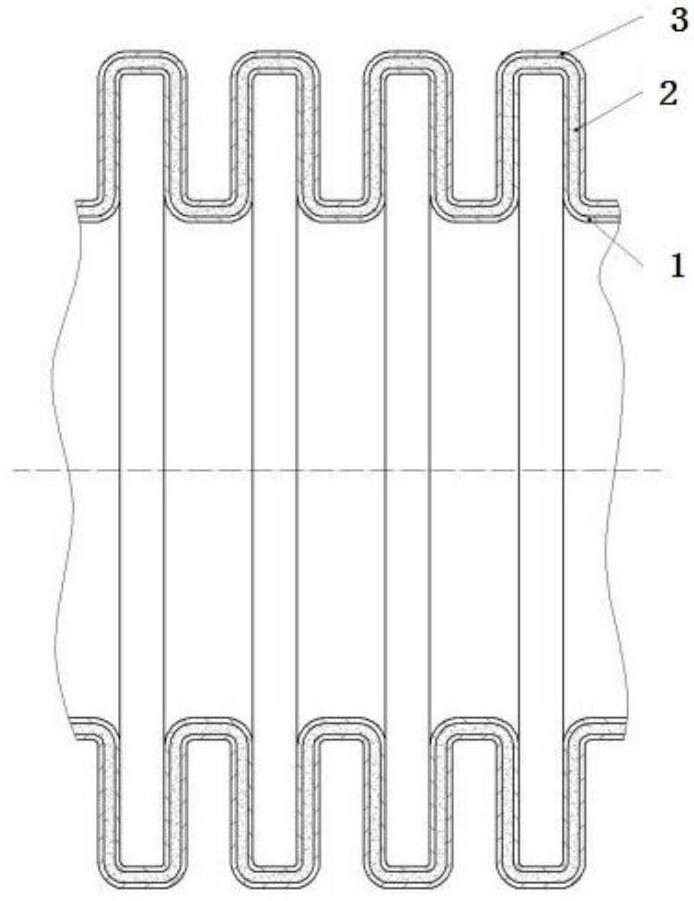

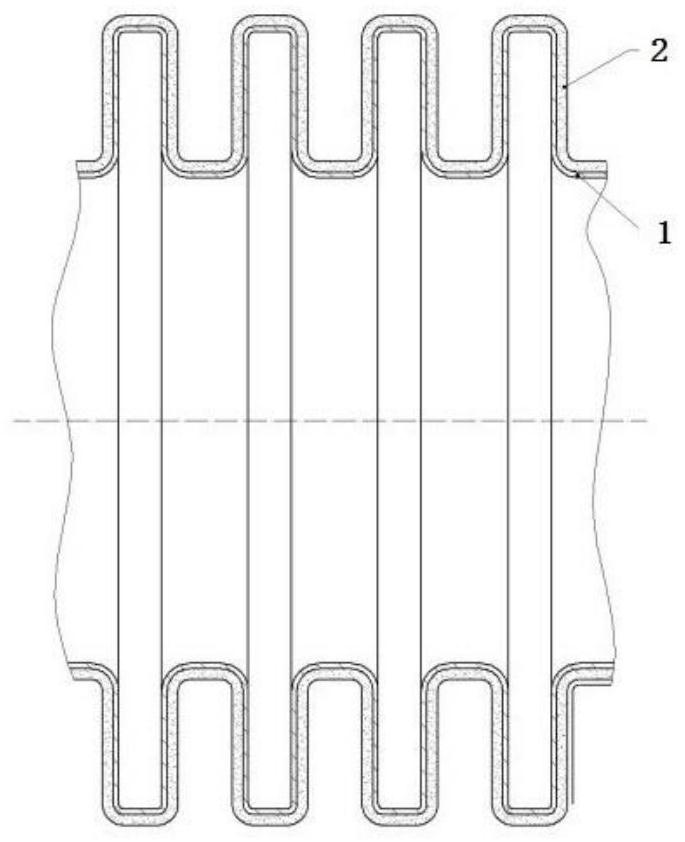

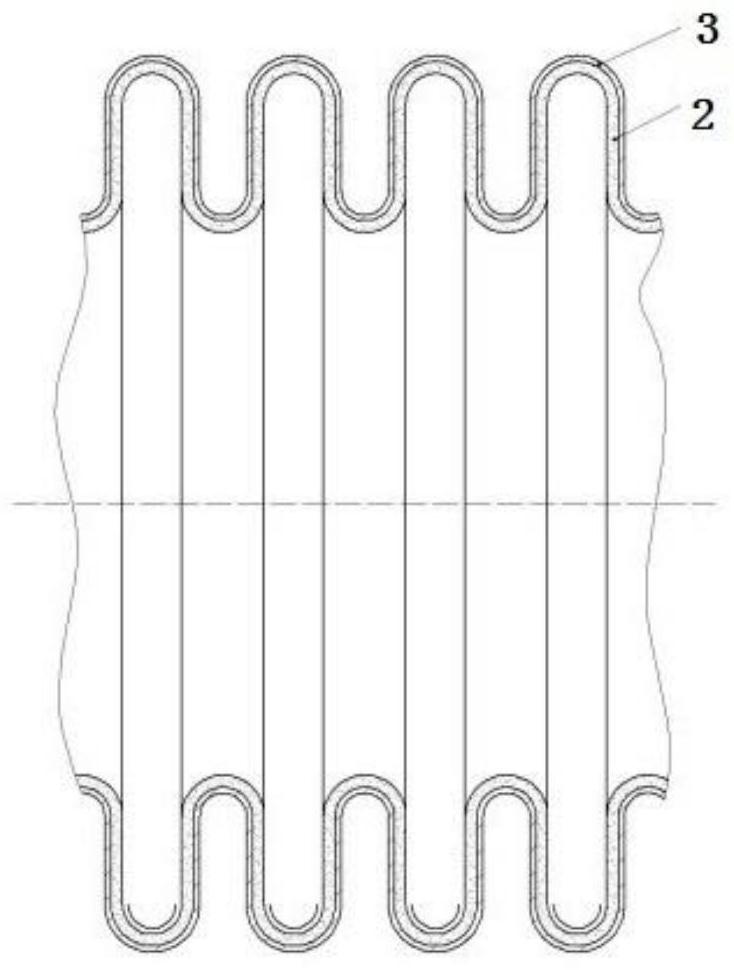

Multi-layer co-extrusion electromagnetic shielding fluoroplastic electric insulation corrugated pipe and preparation method thereof

An electromagnetic shielding and multi-layer co-extrusion technology, which is applied in the direction of magnetic/electric field shielding, insulators, insulators, etc., can solve the urgent demand for high-performance electromagnetic shielding plastic bellows, affect the performance of equipment and electrical appliances, and improve the electromagnetic shielding effect , Improve the effect of strengthening and preventing volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032]In one embodiment according to the present invention, the preparation method of maleic anhydride grafted meltable hydrogen-containing fluoroplastics comprises the following steps: dissolving maleic anhydride in absolute ethanol to prepare a solution with a mass concentration of 30-50%; spraying the solution Pour in the meltable hydrogen-containing fluoroplastics in a high-speed mixer, stir evenly at a high speed, dry in a blast drying oven at 90-100°C for 2-5h, and then irradiate with gamma rays at a temperature of 80-90°C. According to the dose of 1-2 Mrad, the pre-grafting mixture is obtained; the pre-grafting mixture is extruded and granulated by a different-rotational meshing twin-screw extruder to obtain a maleic anhydride grafted meltable hydrogen-containing fluoroplastic.

[0033] Next, the preparation method of the multi-layer co-extrusion electromagnetic shielding fluoroplastic electrical insulation corrugated pipe according to the second aspect of the present in...

Embodiment 1

[0050] First, prepare maleic anhydride grafted ethylene-tetrafluoroethylene (ETFE) copolymer: maleic anhydride is dissolved in absolute ethanol to prepare a solution with a mass concentration of 30%; the solution is sprayed on the ethylene-tetrafluoroethylene in a high-speed mixer In the copolymer (ETFE), stir evenly at a high speed, blow dry at 90° C. for 2 hours in a blast drying oven, and then irradiate with gamma rays at a temperature of 80° C. with a radiation dose of 1 Mrad to obtain a pre-grafted mixture; The pre-grafted mixture is extruded and granulated by a counter-intermeshing twin-screw extruder to obtain maleic anhydride grafted ethylene-tetrafluoroethylene copolymer (ETFE).

[0051] Next, prepare insulating masterbatch: (1) dissolve triallyl isocyanurate (TAIC) in absolute ethanol to prepare a solution with a mass concentration of 30%; (2) spray the solution on ethylene-tetrafluoroethylene in a high-speed mixer Ethylene fluoride copolymer (ETFE) and maleic anhydr...

Embodiment 2

[0055] First, maleic anhydride grafted polyvinylidene fluoride (PVDF): maleic anhydride was dissolved in absolute ethanol to prepare a solution with a mass concentration of 50%; the solution was sprayed in polyvinylidene fluoride (PVDF) in a high-speed mixer, Stir evenly at high speed, dry in a blast drying oven at 90°C for 2 hours, then irradiate with gamma rays at a temperature of 80°C, and the irradiation dose is 1 Mrad to obtain a pre-grafted mixture; the pre-grafted mixture is used Extrude and granulate to an intermeshing twin-screw extruder to obtain maleic anhydride grafted polyvinylidene fluoride (PVDF).

[0056] Next, prepare the insulation masterbatch: (1) dissolve triallyl cyanurate (TAC) in absolute ethanol to prepare a solution with a mass concentration of 50%; (2) spray the solution on polyvinylidene fluoride in a high-speed mixer Ethylene (PVDF) and maleic anhydride grafted polyvinylidene fluoride (PVDF), stirred evenly at high speed, dried in a blast drying ove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com