High-strength antioxidant tin bronze alloy and preparation method thereof

A tin bronze, high-strength technology, applied in the field of high-strength anti-oxidant tin bronze alloy and its preparation, can solve problems such as affecting the service life of equipment, being easy to oxidize but not resistant to pitting corrosion, and affecting use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

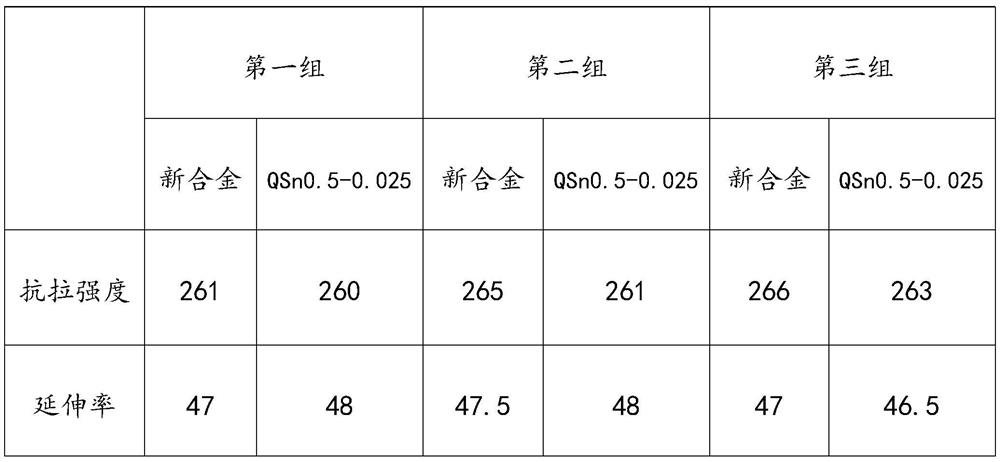

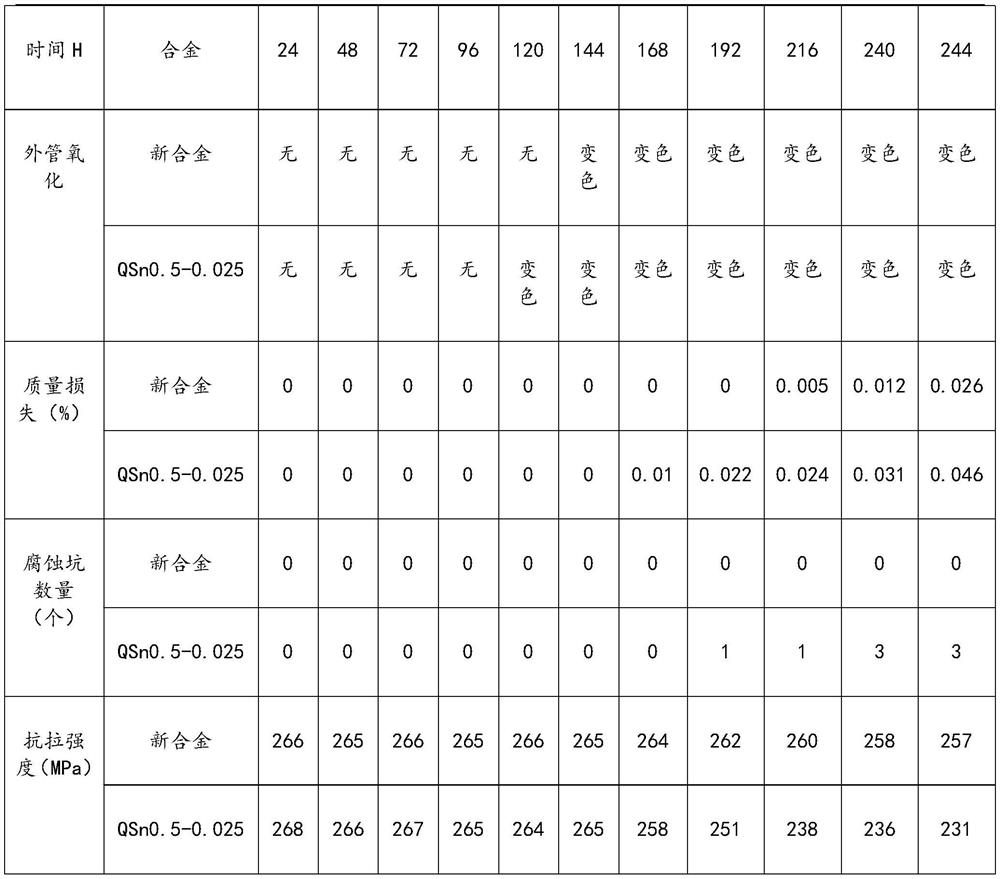

[0022] The technical solutions of the embodiments of the present invention are explained and described below, but the following embodiments are only preferred embodiments of the present invention, not all of them. Based on the examples in the implementation manners, other examples obtained by those skilled in the art without making creative efforts all belong to the protection scope of the present invention.

[0023] The invention discloses a high-strength oxygen-resistant tin bronze alloy, which contains 98% to 99.7% of copper (Cu), 0.01% to 1% of aluminum (Al), 0 to 0.01% of iron (Fe), 0.05% ˜1% tin (Sn), 0.006%˜0.025% phosphorus (P), and the rest are impurities not greater than 0.05%.

[0024] The copper alloy disclosed by the present invention adopts the strengthening method of adding trace elements, adding a trace amount of elements such as Sn to the matrix Cu to form a solid solution, and the influence of a trace amount of Sn element on the grain boundary increases the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com