Photosensitive resin composition and printed wiring board coated with same

A technology of photosensitive resin and composition, applied in printed circuits, printed circuit parts, circuit substrate materials, etc., can solve the problems of decreased thermal shock resistance of insulating protective films, decreased thermal resistance of solders, etc. properties, obtaining thermal shock resistance, and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

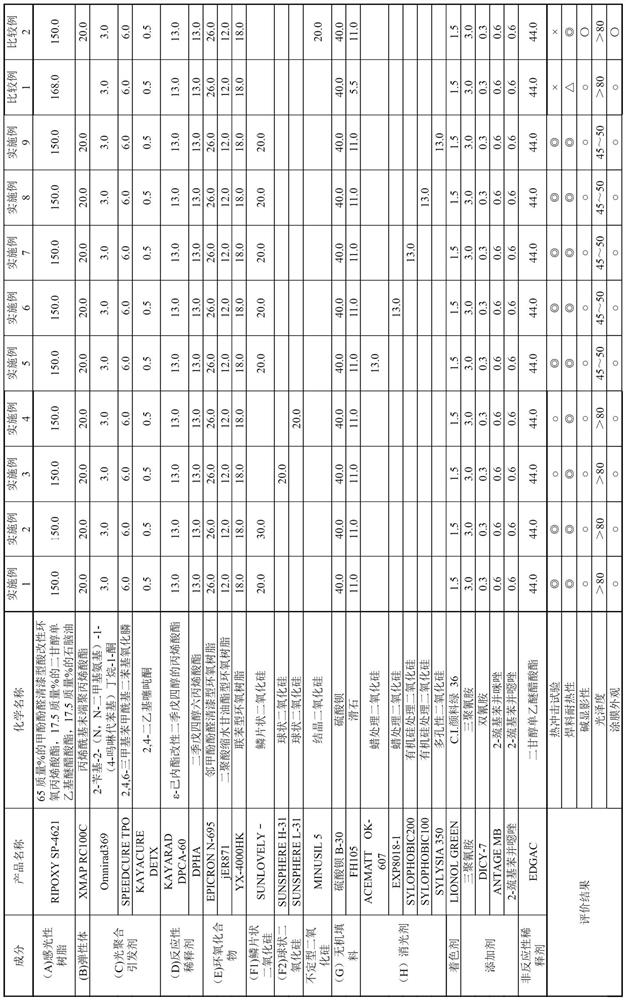

Embodiment 1~9、 comparative example 1~2

[0108] The components shown in the following Table 1 were blended according to the compounding ratio shown in the following Table 1, and mixed and dispersed at room temperature with a triple roll to prepare the photosensitive materials used in Examples 1-9 and Comparative Examples 1-2. resin composition. And the prepared photosensitive resin composition was applied as follows, and the test sample was produced. Unless otherwise stated, the numbers of the compounding quantity in following Table 1 represent a mass part. In addition, blank columns in Table 1 below indicate that the substance was not blended.

[0109] In addition, the detail of each component in following Table 1 is as follows.

[0110] (A) Photosensitive resin

[0111]●RIPOXY SP-4621: Polyacid-modified epoxy acrylate, which is obtained by reacting acrylic acid with at least a part of the epoxy group of cresol novolak type epoxy resin, and making polyacid and the generated epoxy acrylate The chemical structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com