Activated carbon comprehensive utilization co-treatment method

A co-processing, activated carbon technology, applied in chemical instruments and methods, carbon compounds, climate sustainability, etc., can solve problems such as hindering the development of the industry, large equipment footprint, cumbersome and other problems, to increase the calorific value of pyrolysis carbon, The effect of improving energy efficiency and speeding up the response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

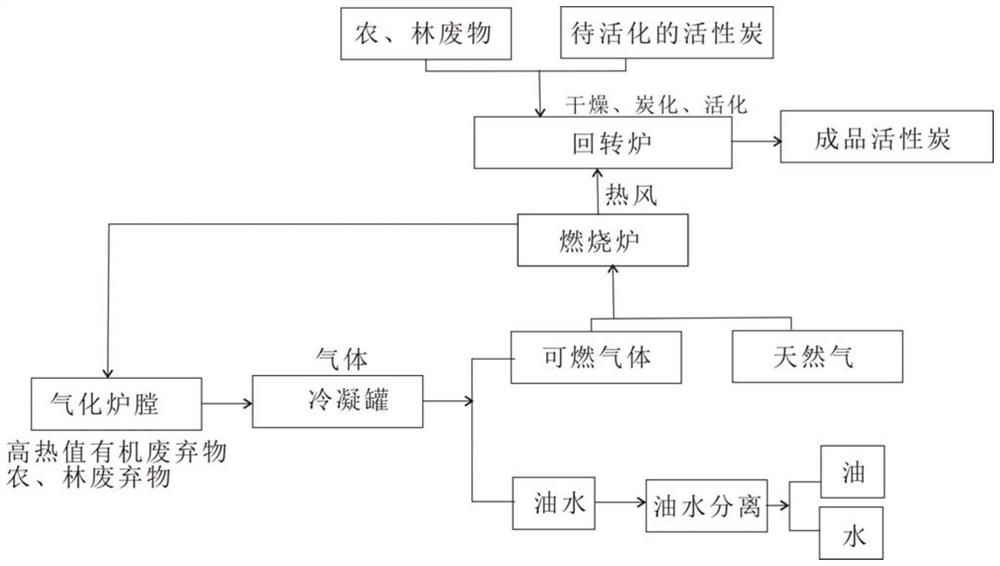

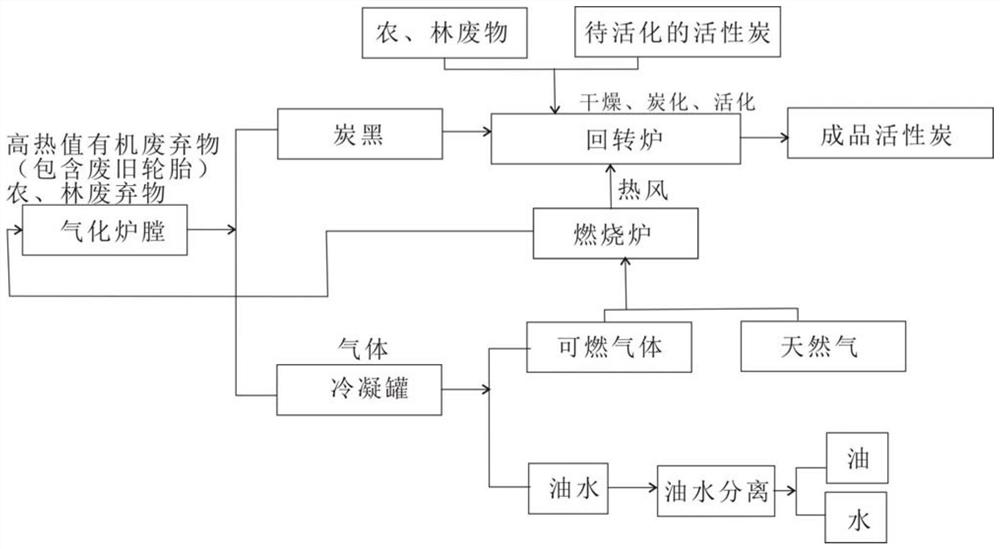

Method used

Image

Examples

Embodiment 1

[0051] A co-processing method for comprehensive utilization of activated carbon, the wastes to be processed include high calorific value organic wastes, agricultural and forestry wastes and special waste gas to be treated: activated carbon to be regenerated;

[0052] High calorific value organic wastes are used tires; agricultural and forestry wastes are walnut shells and corncobs;

[0053] The ratio of waste tires to walnut shells and corn cobs is 2:1:1;

[0054] The amount of waste tires added is 1t, and the total amount of walnut shells and corncobs added is 1t;

[0055] The disposal methods of the above waste are as follows:

[0056] Step 1: Pre-treatment of waste

[0057] Dehydrate high calorific value organic waste, agricultural and forestry waste, and activated carbon to be regenerated to reduce the moisture content to below 10%;

[0058] The dehydration method is to remove the moisture on the surface of the waste through mechanical and physical action;

[0059] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com