Method for detecting service life of steel plate chromium plating solution

A detection method and solution technology, applied in the direction of measuring devices, instruments, particle size analysis, etc., can solve the problems of manufacturers' difficulties, strict discharge requirements, and rising voltage of electroplating tanks, so as to improve the quality of surface coating, improve production quality, and reduce production loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

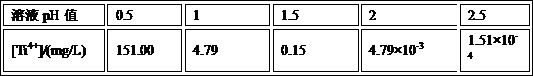

[0068] Take 1L of chrome-plating solution for metal chromium segment newly configured on site, check the pH value of the chrome-plating solution to be 0.7, and add 50mL of 30% hydrogen peroxide to obtain the first solution, using ammonia water with a mass concentration of 30% or sodium carbonate with a concentration of 20g / L Carry out pH value control, the pH value control of the first solution is 3, carry out particle size analysis to the first solution again and obtain the particle size and the frequency distribution of the impurity ion in the first solution, and adopt centrifugal sedimentation to obtain deposit, centrifugal sedimentation speed is 3000~5000rpm, the sediment is dried and weighed.

[0069] The test results are: when the pH value of the first solution is adjusted to 3, the frequency distribution of impurity ions with a particle size of 5.6-20.0 μm is 68.89%, which is less than 70%, and the corresponding sediment mass is less than 0.2g. A relational model obtain...

Embodiment 2

[0071] Take 1L of chrome-plating solution for the metal chromium section on site, detect that the pH value of the chrome-plating solution is 0.98, and add 50mL of 30% hydrogen peroxide to obtain the first solution, and use 30% ammonia water or 20g / L sodium carbonate to measure the pH value. value control, first adjust the pH value to 3, and then conduct particle size analysis on the first solution to obtain the particle size and frequency distribution of impurity ions in the first solution, and use centrifugal sedimentation to obtain sediment. The centrifugal sedimentation speed is 3000~5000rpm. The sediment was dried and weighed, and the obtained impurity ions with a particle size of 5.6-20.0 μm did not satisfy the conditions in the first relational model.

[0072] Sampling metal chromium section chrome plating solution 1L again from the spot, detects that the pH value of this chromium plating solution is 0.98, and adds 30% hydrogen peroxide 50mL to obtain the first solution, ...

Embodiment 3

[0074]Take 1L of the on-site chromium oxide section chromium plating solution as the first solution, detect that the pH value of the chromium plating solution is 1.08, and add 50mL of 30% hydrogen peroxide to obtain the first solution, using ammonia water with a mass concentration of 30% or a concentration of 20g / L Sodium carbonate is carried out pH value adjustment, and the pH value value adjustment range is 3~6, and the first solution is carried out particle size analysis to obtain the particle size and the frequency distribution of the impurity ion in the first solution after adjusting the pH value each time, and adopt centrifugal sedimentation to obtain For the sediment, the centrifugal sedimentation speed is 3000~5000rpm, and the sediment is dried and weighed. When the pH value is controlled at a certain value, if the frequency distribution of impurity ions of corresponding particle size in the first solution or the quality of the sediment do not meet the conditions in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com