Negative pole piece and lithium ion battery

A technology of negative pole piece and conductive agent, which is applied in the field of negative pole piece and lithium-ion battery, can solve the problems of large volume expansion, achieve the effects of inhibiting volume expansion, increasing battery capacity, and preventing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment is used to illustrate a negative electrode sheet and its preparation method disclosed in the present invention.

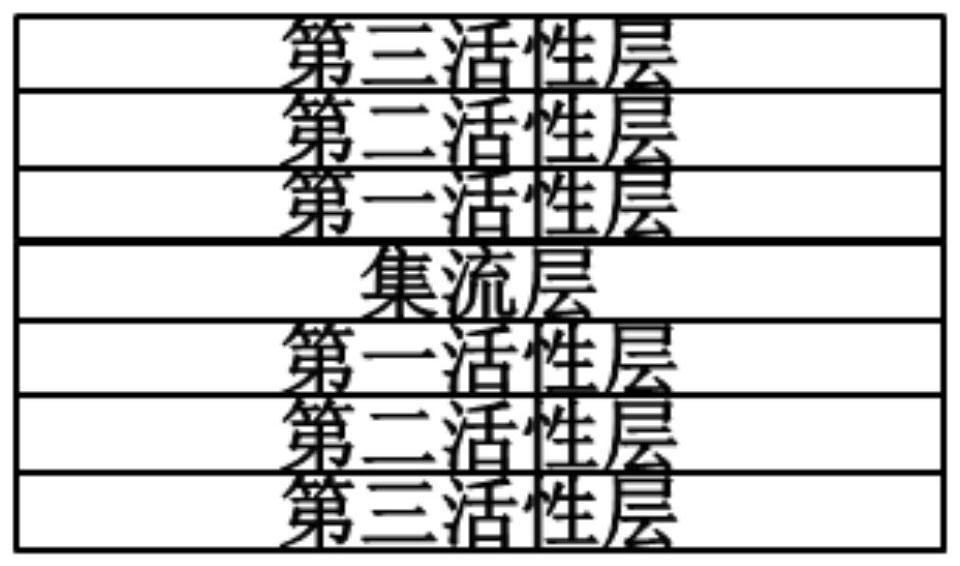

[0036] A mixture of silicon oxide as the first active material and graphite material as the second active material with a mass fraction of 80:20 is used as an active material material, and the active material material, the conductive material SP, and the binder material PAA are formulated according to The first negative electrode slurry L1 was prepared in parts by mass of 85:5:10. A mixture of silicon oxide as the first active material and natural graphite material as the second active material with a mass fraction of 50:50 is used as another active material, and the other active material is bonded to the conductive material SP, The agent material SBR and the thickener CMC were mixed according to the mass ratio of 95:5:2:3 to prepare the second negative electrode slurry L2. The first negative electrode slurry L1 is first coated on the curren...

Embodiment 2

[0038] This embodiment is used to illustrate another negative electrode sheet disclosed in the present invention and its preparation method.

[0039] The commercial 1200 silicon carbon as the first active material and the graphite mixture as the second active material with a weight ratio of 70:30 are used as an active material, and the active material and the conductive material SP and the binder material PAA are used according to 80 : 6.5: 13.5 mass ratio to make the first negative electrode slurry L1. The commercial 1200 silicon carbon as the first active material and the graphite mixture as the second active material with a weight ratio of 80:20 are used as another active material material, and the active material material is combined with the conductive material SP, the binder material SBR, The thickener CMC is used to make the second negative electrode slurry L2 according to the mass ratio of 95:5:2:3, and the first negative electrode slurry L1 is first coated on the copp...

Embodiment 3

[0041] This embodiment is used to illustrate another negative electrode sheet disclosed in the present invention and its preparation method.

[0042] The first active material commercial tin and the second active material graphite mixture with a weight ratio of 80:20 are used as an active material material, and the active material material, the conductive material SP, and the binder material PAA are used according to the mass ratio of 85:5:10 Compared with making the first negative electrode slurry L1, the artificial graphite material, the conductive material SP, the binder material SBR, and the thickener CMC are made into the second negative electrode slurry L2 according to the mass ratio of 95:5:2:3, and the first The negative electrode slurry L1 is first coated on the copper foil to obtain the first active material layer, after drying and pressing, the second negative electrode slurry L2 is coated on the first layer of active material layer, after drying and pressing, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com