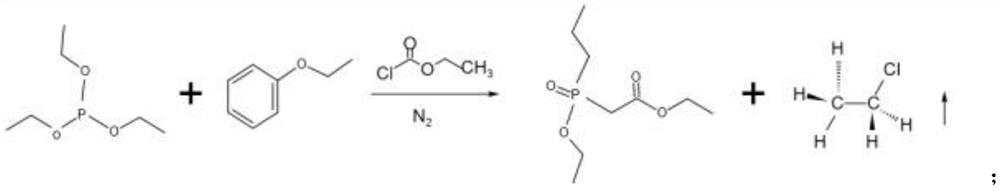

Preparation method of triethyl phosphonoacetate

A technology of triethyl phosphoroacetate and triethyl phosphite, which is applied in the field of preparation of triethyl phosphoroacetate, can solve the problems of low purity, high production cost, and low yield, and achieve high purity and low cost. Low, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 3mol phenethyl ether and 1mol triethyl phosphite into the reaction kettle, then raise the temperature to 120°C, slowly add 1mol ethyl chloroacetate dropwise, the released ethyl chloride will co-produce ethyl chloride in the absorption tank; add chloroacetic acid dropwise Ethyl ester was kept at 120°C for 3h. Nitrogen gas was introduced into the reaction kettle for 1h, and the ethyl chloride was driven off to make the reaction complete. The material is pumped into a distillation pot, and distilled under reduced pressure at 150°C. The first fraction is collected, mainly raw materials and phenetole, and the later fraction is collected at 500 Pa and 150°C, monitored by gas chromatography, and the finished product is obtained.

[0026] Add 3mol sodium phenoxide solution into the absorption kettle to capture ethyl chloride from the upper reaction kettle, keep the temperature of the absorption kettle at 80°C, cool and separate the layers after absorption, pump the oil laye...

Embodiment 2

[0028] Add 2mol phenethyl ether and 1mol triethyl phosphite into the reaction kettle, then raise the temperature to 130°C, slowly add 2mol ethyl chloroacetate dropwise, the released ethyl chloride will co-produce ethyl chloride in the absorption tank; add chloroacetic acid dropwise Ethyl ester was kept at 120°C for 3h. Nitrogen gas was introduced into the reaction kettle for 2h, and the ethyl chloride was driven out to make the reaction complete. The material is pumped into a distillation pot, and distilled under reduced pressure at 150°C. The first fraction is collected, mainly raw materials and phenetole, and the later fraction is collected at 500 Pa and 140°C, monitored by gas chromatography, and the finished product is obtained.

[0029] Add 4mol sodium phenoxide solution into the absorption kettle to capture the ethyl chloride escaped from the upper reaction kettle, keep the temperature of the absorption kettle at 75°C, cool and separate the layers after absorption, pump ...

Embodiment 3

[0031] Add 4mol phenethyl ether and 1mol triethyl phosphite into the reaction kettle, then raise the temperature to 130°C, slowly add 3mol ethyl chloroacetate dropwise, the released ethyl chloride will co-produce ethyl chloride in the absorption tank; add chloroacetic acid dropwise Ethyl ester was kept at 125°C for 4h. Nitrogen gas was introduced into the reaction kettle for 1h, and the ethyl chloride was driven off to make the reaction complete. The material is pumped into a distillation kettle, and distilled under reduced pressure at 150°C. The first fraction is collected, mainly raw materials and phenetole, and the later fraction is collected at 600 Pa and 150°C, monitored by gas chromatography, and the finished product is obtained.

[0032] Add 6mol sodium phenoxide solution into the absorption kettle to capture the ethyl chloride escaped from the upper reaction kettle, keep the temperature of the absorption kettle at 75°C, cool and separate the layers after absorption, pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com