Silicon carbide single crystal and growth device and preparation method thereof

A silicon carbide single crystal and growth device technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve problems such as the appearance of large steps at the interface, stacking fault polytype inclusions, etc., and achieve reduction Defects, avoid condensation, inhibit growth effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

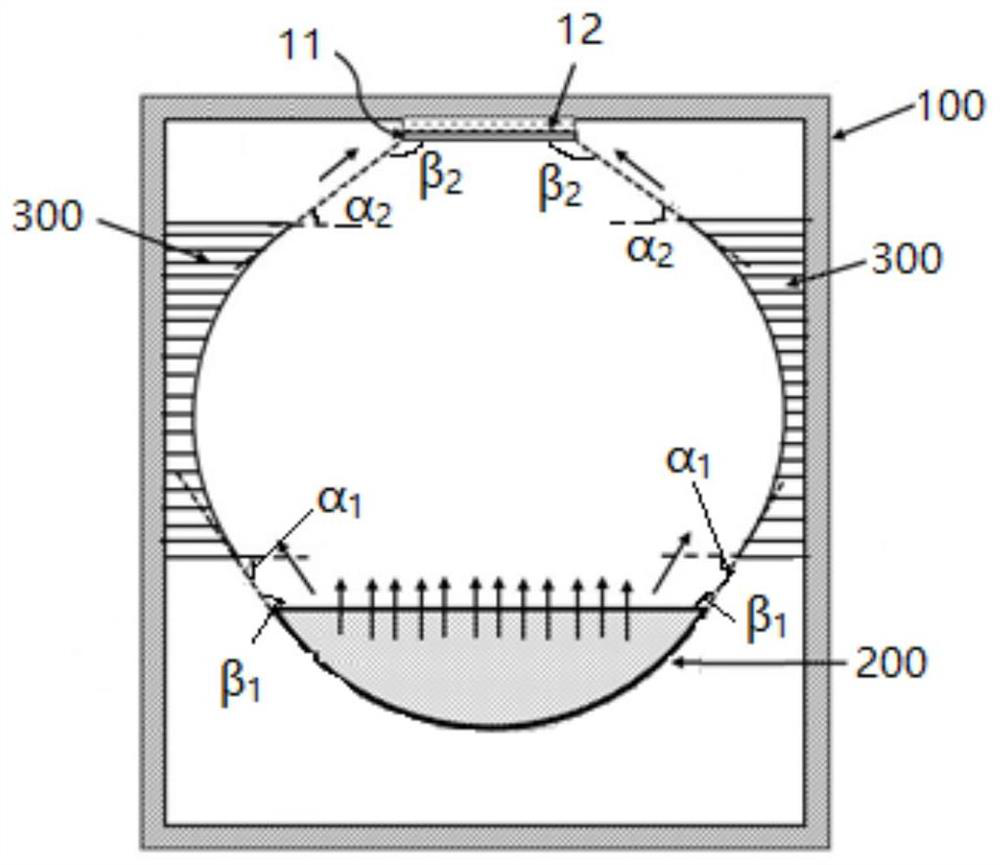

[0072] refer to Figure 5 , The silicon carbide single crystal growth device comprises a growth crucible 100, an inner crucible 200 (made of graphite), a guide tube 300 (made of graphite), an inner crucible base 400 (made of graphite) and a rotating shaft 500 (made of graphite) , the inner crucible 200 adopts a pot-like wide-caliber, the seed crystal 11 is fixed on the top center of the growth crucible 100 through the seed crystal base 12, silicon carbide powder is placed in the inner crucible 200, and the outer wall of the inner crucible 200 is close to and fixed on On the inner wall of the inner crucible base 400, the guide tube 300 is arranged between the seed crystal 11 and the inner crucible 200 and surrounds the inner wall of the growth crucible 100, and the inner wall of the guide tube 300 is in the shape of a smooth arc, and the inner crucible 200 and the guide The flow tube 300 cooperates to form a gas transmission and drainage channel, the tangent line of the lower e...

Embodiment 2

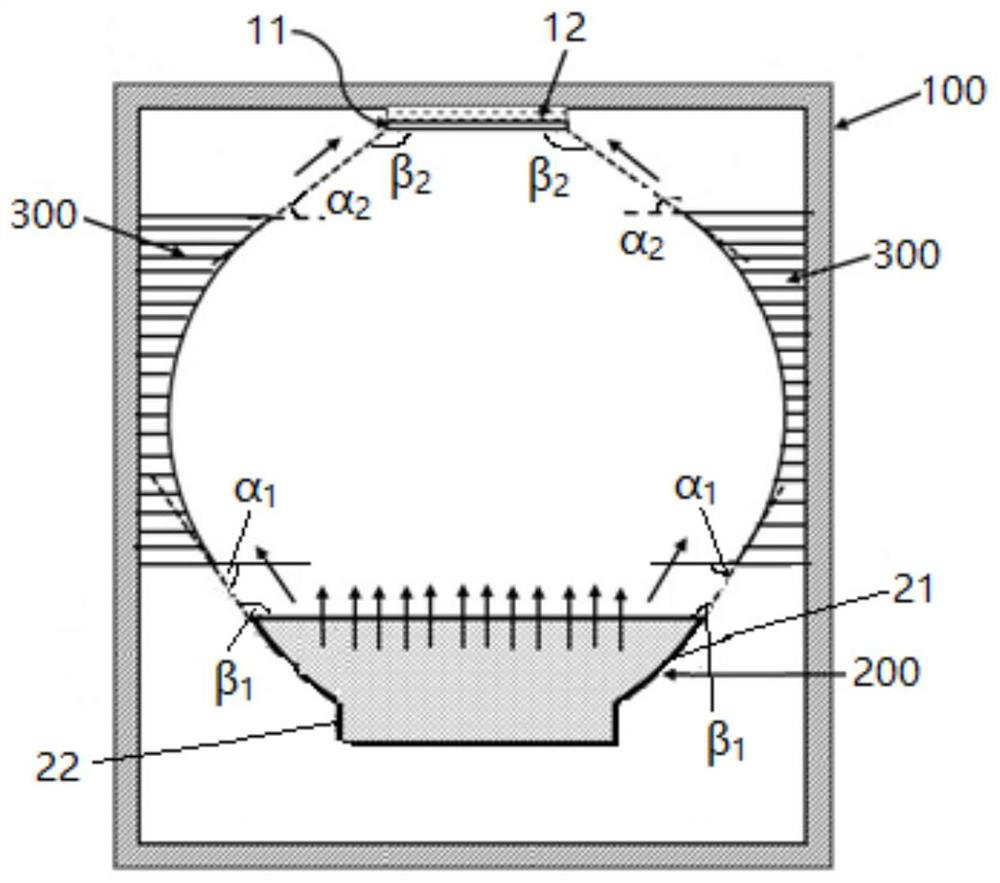

[0074] refer to Image 6 , the inner crucible 200 is adopted from top to bottom and includes a reduced diameter portion 21 and an equal diameter portion 22, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com