Lead paste additive for lead-carbon battery and lead-carbon battery

A lead-carbon battery and additive technology, applied in battery electrodes, lead-acid batteries, secondary batteries, etc., can solve the problems of weakened bonding strength between active materials, large structural differences, large volume changes, etc., to improve charge acceptance , The effect of reducing the softening rate and improving the strength of the plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

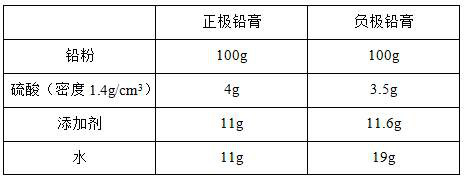

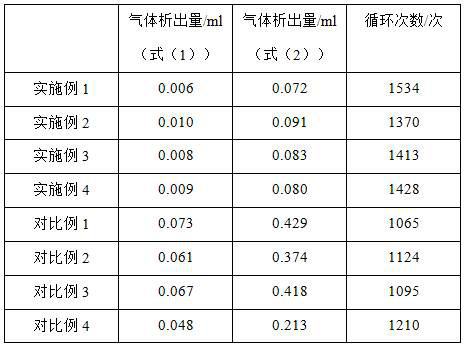

Examples

Embodiment 1

[0029] A lead paste additive for a lead-carbon battery, comprising a positive lead paste additive and a negative lead paste additive; the positive lead paste additive comprises, in parts by weight: 10 parts of graphene, 25 parts of modified diatomite, 65 parts of conductive glue.

[0030] Adopting the above-mentioned positive electrode paste additive can effectively improve the cycle life and reduce the amount of gas evolution. The above-mentioned positive electrode paste additive can be strongly adsorbed on the active material of the positive plate, so that a conductive network is formed between the fine active materials, not only Greatly enhance the conductivity between the active materials, and at the same time enhance the connection strength between the active materials, so that the softening rate of the active materials of the positive plate is greatly reduced, effectively improve the strength of the plate, and improve the charge acceptance of the battery And reduce the p...

Embodiment 2

[0042] A lead paste additive for lead-carbon batteries, including a positive lead paste additive and a negative lead paste additive;

[0043] The positive electrode paste additive includes, in parts by weight: 6 parts of graphene, 30 parts of modified diatomaceous earth, and 64 parts of conductive glue.

[0044] The conductive adhesive is prepared from 30 parts by weight of N-methylpyrrolidone, 4 parts by weight of polyvinylidene fluoride, and 1 part by weight of conductive carbon black.

[0045] The preparation method of described modified diatomite is:

[0046] S1. Add 6 parts by weight of diatomite and 0.5 parts by weight of humic acid to 30 parts by weight of citric acid aqueous solution with a mass fraction of 10%, stir at 200 rpm for 20 minutes, filter, and dry to obtain pretreated diatomite;

[0047] S2. Add 6 parts by weight of triethylamine and 6 parts by weight of bromoalkyldiphenylphosphine oxide to 30 parts by weight of tetrahydrofuran, stir at 80°C at 200rpm for ...

Embodiment 3

[0051] A lead paste additive for lead-carbon batteries, including a positive lead paste additive and a negative lead paste additive;

[0052] The positive electrode paste additive includes, by weight, 15 parts of graphene, 15 parts of modified diatomite, and 70 parts of conductive glue.

[0053] The conductive adhesive is prepared from 50 parts by weight of N-methylpyrrolidone, 1 part by weight of polyvinylidene fluoride, and 5 parts by weight of conductive carbon black.

[0054] The preparation method of described modified diatomite is:

[0055] S1. Add 12 parts by weight of diatomite and 2 parts by weight of humic acid to 50 parts by weight of an 8% citric acid aqueous solution, stir at 400 rpm for 18 minutes, filter, and dry to obtain pretreated diatomite;

[0056] S2. Add 4 parts by weight of triethylamine and 4 parts by weight of bromoalkyldiphenylphosphine oxide to 50 parts by weight of tetrahydrofuran, stir at 80°C at 600rpm for 2h, and at 75°C under a pressure of 0.1P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com