High-strength TC4-BN alloy containing isometric crystal and columnar crystal mixed structure and preparation method of high-strength TC4-BN alloy

A TC4-BN, columnar crystal technology, applied in the field of additive manufacturing, can solve the problem of insignificant increase in the strength of titanium alloys, and achieve the effects of wide application range, expansion of application fields, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

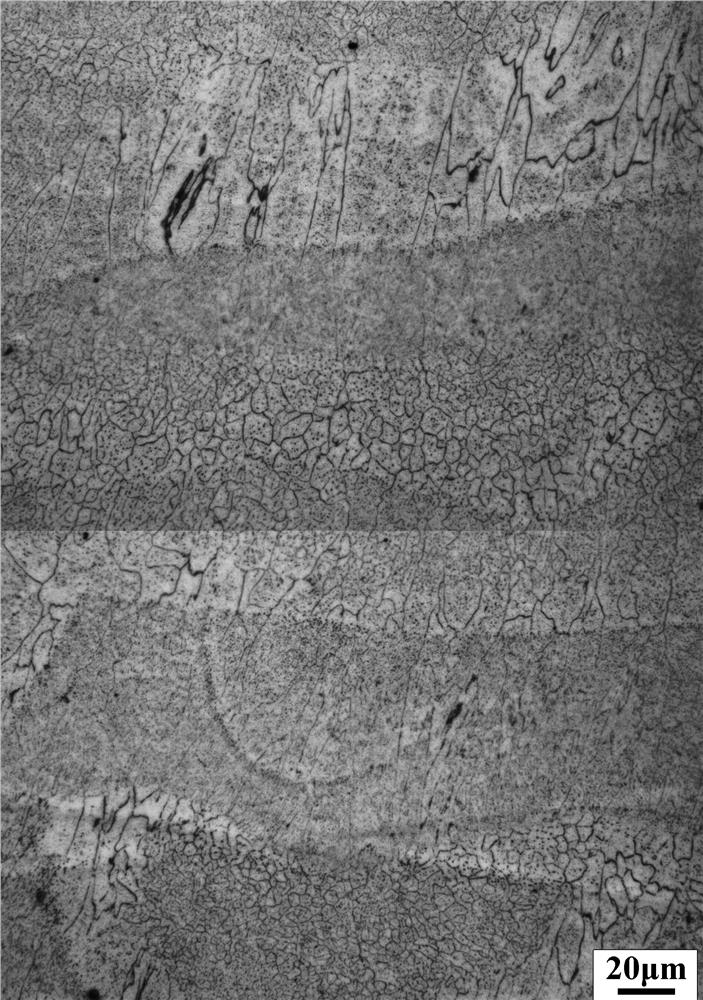

[0028] A high-strength TC4-BN alloy containing a mixed structure of equiaxed crystals and columnar crystals and a preparation method thereof, comprising the following steps:

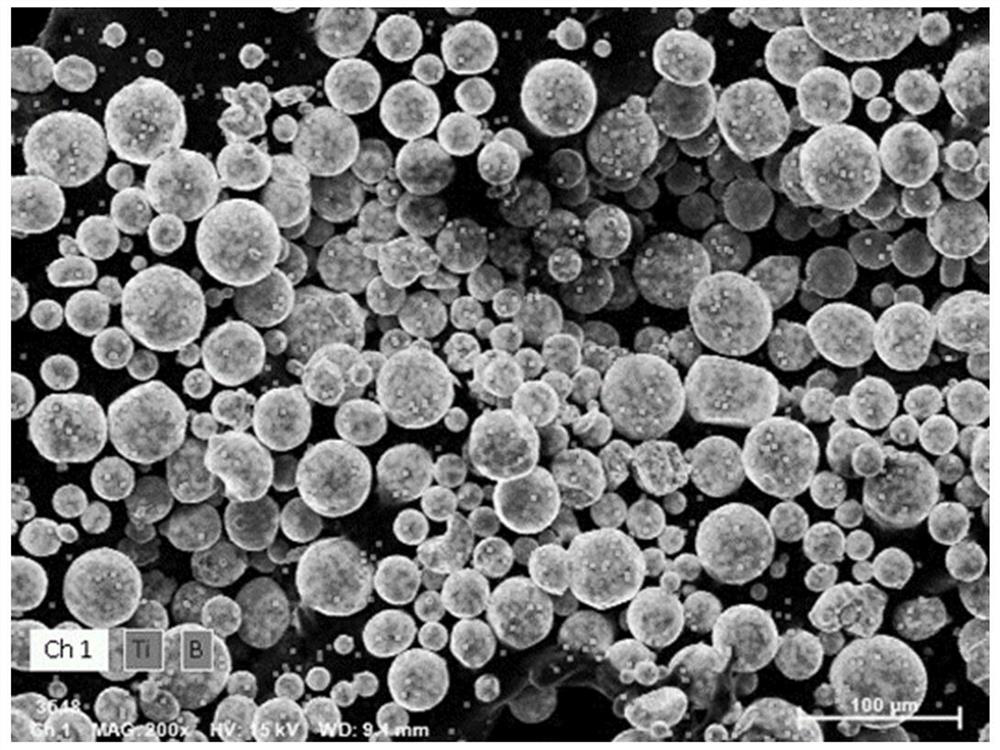

[0029] (1) Sieve the BN powder and TC4 alloy powder separately, and mix the obtained BN powder with a particle size of 1-3 μm, TC4 alloy powder with a particle size of 15-53 μm and stainless steel balls with a diameter of 3 mm in proportion and place them in a ball mill Inside, the amount of BN added is 0.5wt%, the mass ratio of stainless steel balls to powder is 4:1, and then the ball mill tank is evacuated to make the pressure inside the tank reach below 0.05MPa.

[0030] (2) Fix the ball mill jar in the planetary ball mill for ball milling, the rotation speed is 250r / min, the ball milling time is 3 hours, the start-stop time ratio of the ball mill is 2:1, so that the two powders are evenly mixed, and then the obtained powder is subjected to vacuum Package preservation.

[0031] (3) TC4-0.5wt%BN mixed...

Embodiment 2

[0035] A high-strength TC4-BN alloy containing a mixed structure of equiaxed crystals and columnar crystals and a preparation method thereof, comprising the following steps:

[0036] (1) Sieve the BN powder and TC4 alloy powder separately, and mix the obtained BN powder with a particle size of 1-3 μm, TC4 alloy powder with a particle size of 15-53 μm and stainless steel balls with a diameter of 3 mm in proportion and place them in a ball mill Inside, the amount of BN added is 0.3wt%, the mass ratio of stainless steel balls to powder is 3:1, and then the ball mill tank is evacuated to make the pressure inside the tank reach below 0.05MPa.

[0037](2) Fix the ball mill tank in the planetary ball mill for ball milling, the speed of which is 300r / min, the ball milling time is 2 hours, and the start-stop time ratio of the ball mill is 2:1, so that the two powders are evenly mixed, and then the obtained powder is subjected to vacuum Package preservation.

[0038] (3) Using TC4-0.3w...

Embodiment 3

[0042] A high-strength TC4-BN alloy containing a mixed structure of equiaxed crystals and columnar crystals and a preparation method thereof, comprising the following steps:

[0043] (1) Sieve the BN powder and TC4 alloy powder separately, and mix the obtained BN powder with a particle size of 1-3 μm, TC4 alloy powder with a particle size of 15-53 μm and stainless steel balls with a diameter of 3 mm in proportion and place them in a ball mill Inside, the amount of BN added is 0.8wt%, the mass ratio of stainless steel balls to powder is 8:1, and then the ball mill tank is evacuated to make the pressure inside the tank reach below 0.05MPa.

[0044] (2) Fix the ball mill jar in the planetary ball mill for ball milling, the rotation speed is 200r / min, the ball milling time is 4 hours, the start-stop time ratio of the ball mill is 1:1, so that the two powders are evenly mixed, and then the obtained powder is subjected to vacuum Package preservation.

[0045] (3) Using TC4-0.8wt%BN...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com