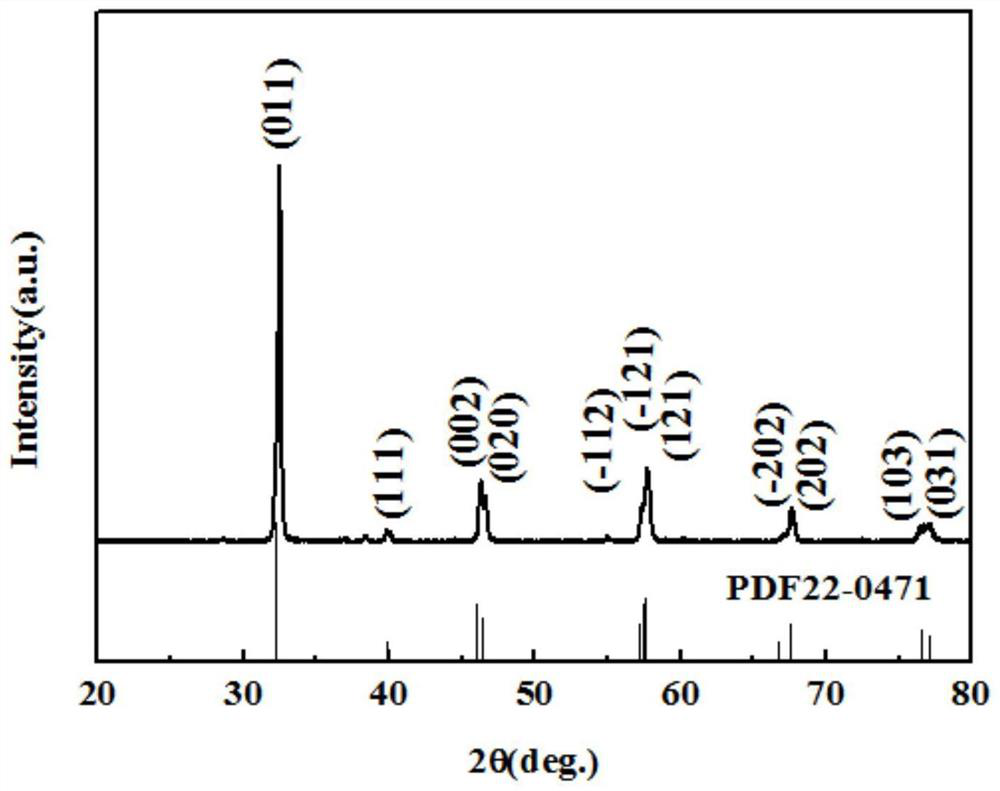

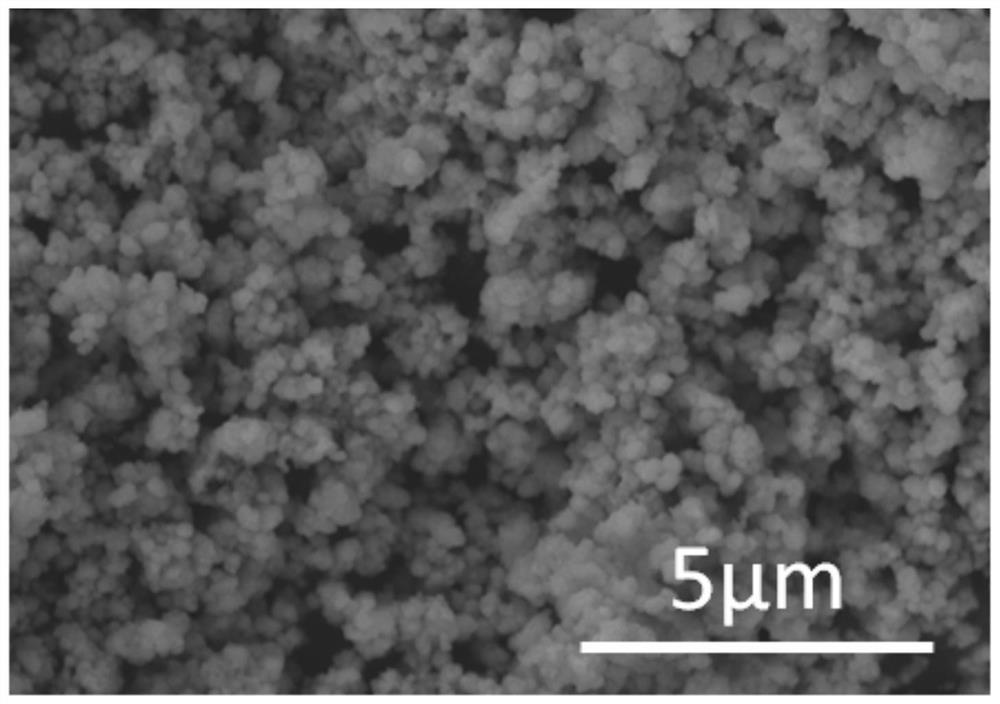

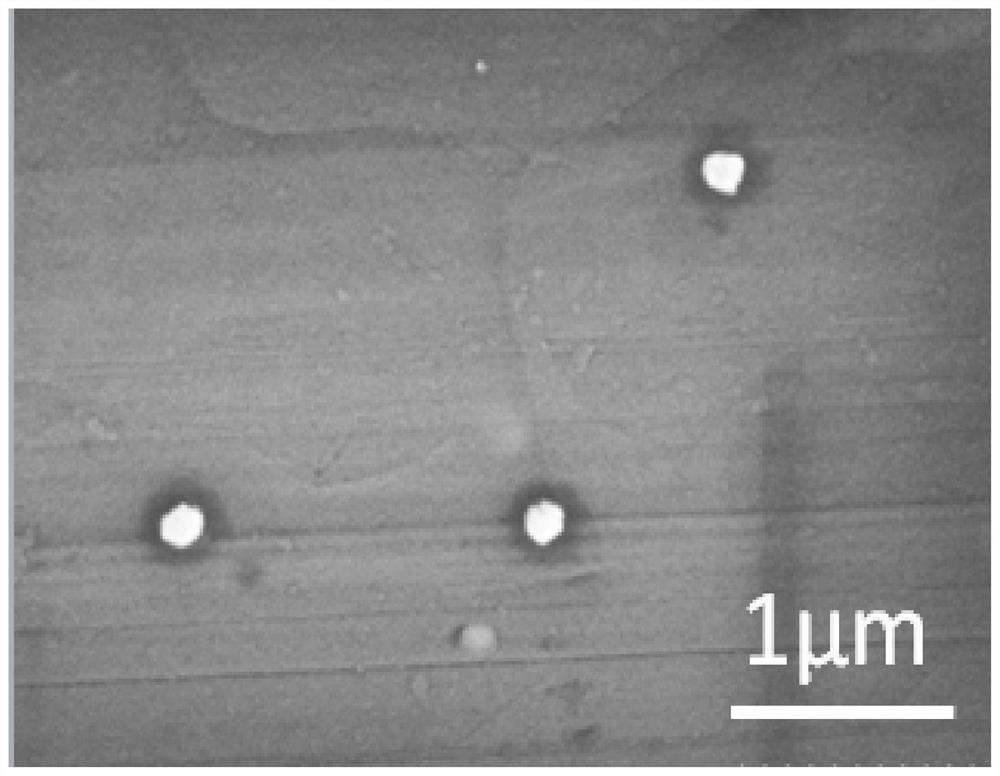

Nano silver niobate powder prepared by coprecipitation method and method

A co-precipitation method, silver niobate technology, applied in chemical instruments and methods, niobium compounds, inorganic chemistry, etc., can solve the problems of powder not fine enough, high energy consumption, difficult to control the powder size, etc., to achieve easy preparation conditions The effect of control, simple preparation process and short synthesis cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of co-precipitation method of the present invention prepares the method for nano-silver niobate powder, comprises the following steps:

[0036] (1) Press Nb 2 o 5 :AgNO 3 =1:2, Nb 2 o 5 :C 2 h 2 o 4 =1:2, AgNO 3 :C 2 h 2 o 4 =1:2 molar ratio weighs 9g and 18g of C 2 h 2 o 4 Soluble in deionized water at 60°C, the concentration is 0.07mol / L;

[0037] (2) Press Nb 2 o5 :AgNO 3 =1:2 molar ratio weighs 13.3g of Nb 2 o 5 and 17g of AgNO 3 , and then add C in step (1) respectively 2 h 2 o 4 In the solution, stir for 2 hours with a magnetic stirrer;

[0038] (3) AgNO 3 C 2 h 2 o 4 The solution was added dropwise to Nb 2 o 5 C 2 h 2 o 4 In solution, obtain mixed solution, stir 4 hours with magnetic stirrer;

[0039] (4) Adjust the pH value of the mixed solution to 2 with ammonia water and keep it stable for 15 minutes. Press C 2 h 2 o 4 :(CH 2 Oh) 2 =1:2 molar ratio takes by weighing 37.2g (CH 2 Oh) 2 Adding to the mixed solution, ...

Embodiment 2

[0045] A kind of co-precipitation method of the present invention prepares the method for nano-silver niobate powder, comprises the following steps:

[0046] (1) Press Nb 2 o 5 :AgNO 3 =1:2, Nb 2 o 5 :C 2 h 2 o 4 =1:2, AgNO 3 :C 2 h 2 o 4 =1:2 molar ratio weighs 1.8g and 3.6g of C 2 h 2 o 4 Soluble in deionized water at 30°C, the concentration is 0.05mol / L;

[0047] (2) Press Nb 2 o 5 :AgNO 3 =1:2 molar ratio weighs 2.66g of Nb 2 o 5 and 3.4g of AgNO 3 , and then add C in step (1) respectively 2 h 2 o 4 In the solution, stir for 2 hours with a magnetic stirrer;

[0048] (3) AgNO 3 C 2 h 2 o 4 The solution was added dropwise to Nb 2 o 5 C 2 h 2 o 4 In solution, obtain mixed solution, stir 4 hours with magnetic stirrer;

[0049] (4) Adjust the pH value of the mixed solution to 2 with ammonia water and keep it stable for 15 minutes. Press C 2 h 2 o 4 :(CH 2 Oh) 2 =1:2 molar ratio takes by weighing 7.44g (CH 2 Oh) 2 Adding to the mixed solu...

Embodiment 3

[0053] A kind of co-precipitation method of the present invention prepares the method for nano-silver niobate powder, comprises the following steps:

[0054] (1) Press Nb 2 o 5 :AgNO 3 =1:2, Nb 2 o 5 :C 2 h 2 o 4 =1:2, AgNO 3 :C 2 h 2 o 4 =1:2 molar ratio weighs 3.6g and 7.2g of C 2 h 2 o 4 Soluble in deionized water at 45°C, the concentration is 0.05mol / L;

[0055] (2) Press Nb 2 o 5 :AgNO 3 =1:2 molar ratio weighs 5.32g of Nb 2 o 5 and 6.8g of AgNO 3 , and then add C in step (1) respectively 2 h 2 o 4 In the solution, stir for 2 hours with a magnetic stirrer;

[0056] (3) AgNO 3 C 2 h 2 o 4 The solution was added dropwise to Nb 2 o 5 C 2 h 2 o 4 In solution, obtain mixed solution, stir 4 hours with magnetic stirrer;

[0057] (4) Adjust the pH value of the mixed solution to 2 with ammonia water and keep it stable for 15 minutes. Press C 2 h 2 o 4 :(CH 2 Oh) 2 =1:2 molar ratio takes by weighing 14.88g (CH 2 Oh) 2 Adding to the mixed sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com