Dry-mixed adhesive mortar prepared from coal gangue and fly ash and preparation method of dry-mixed adhesive mortar

A technology for bonding mortar and coal gangue, which is applied in the field of dry-mixed bonding mortar and its preparation, can solve the problems of limited usage of coal gangue, achieve important ecological and environmental benefits, improve tensile performance, and reduce mining steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

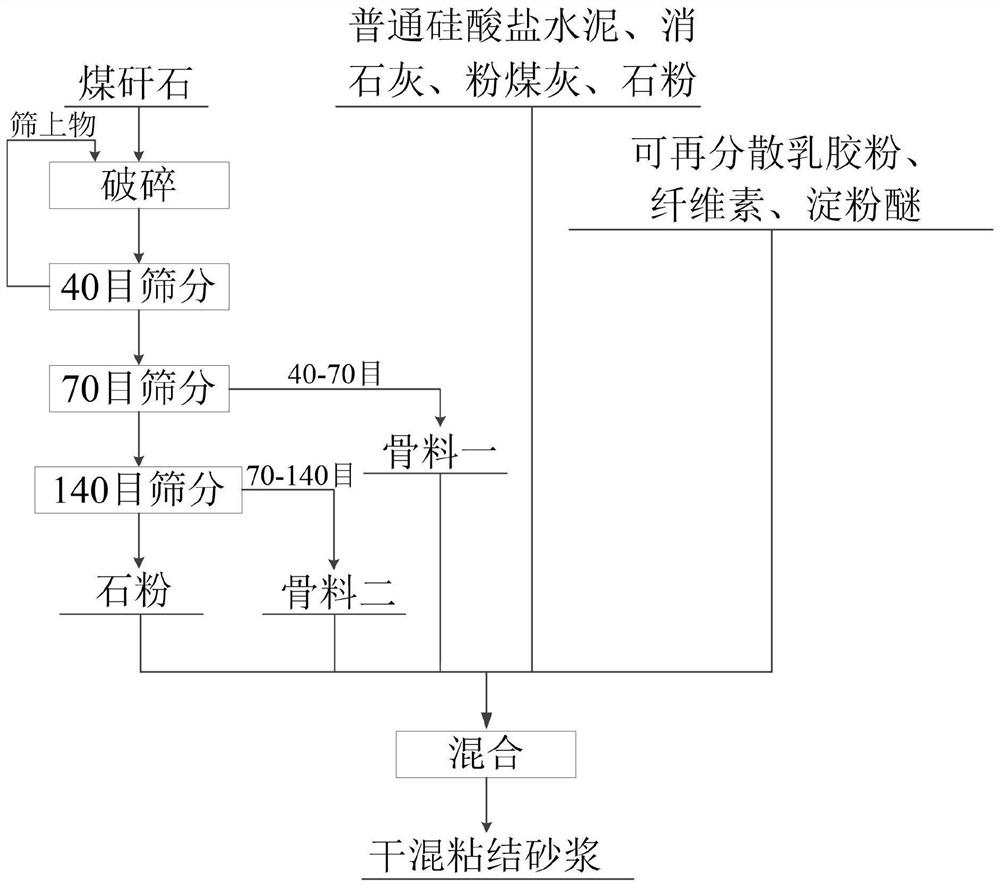

[0029] The present invention also provides a preparation method for the above-mentioned dry-mixed adhesive mortar, comprising the following steps:

[0030] Mix gangue aggregate, stone powder, ordinary portland cement, slaked lime, fly ash, redispersible latex powder, cellulose, and starch ether to obtain a dry-mixed adhesive mortar prepared with coal gangue and fly ash.

Embodiment 1

[0033] The coal gangue is crushed with an impact crusher, screened and classified with 40 mesh, 70 mesh, and 140 mesh square hole screens, the particle size of aggregate 1 is less than or equal to 40 mesh and greater than 70 mesh, and the particle size of aggregate 2 is less than or equal to 70 mesh is greater than or equal to 140 mesh, and below 140 mesh is stone powder. Mix Aggregate 1, Aggregate 2, ordinary Portland cement, slaked lime, fly ash, stone powder, redispersible latex powder, cellulose, and starch ether according to the parts by mass in Table 1.

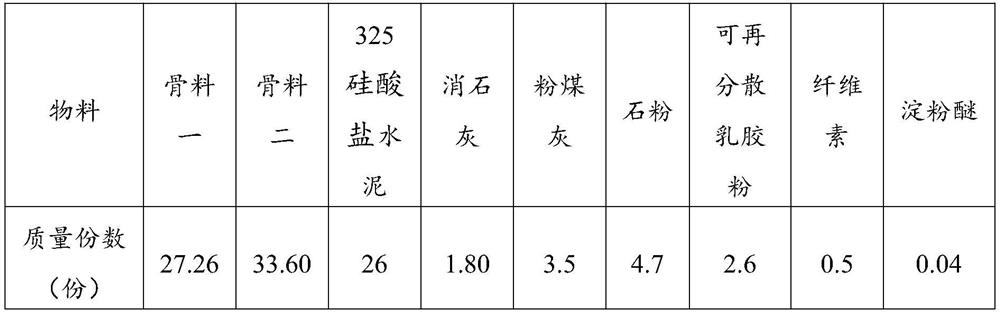

[0034] Table 1 embodiment 1 each material adds mass parts

[0035]

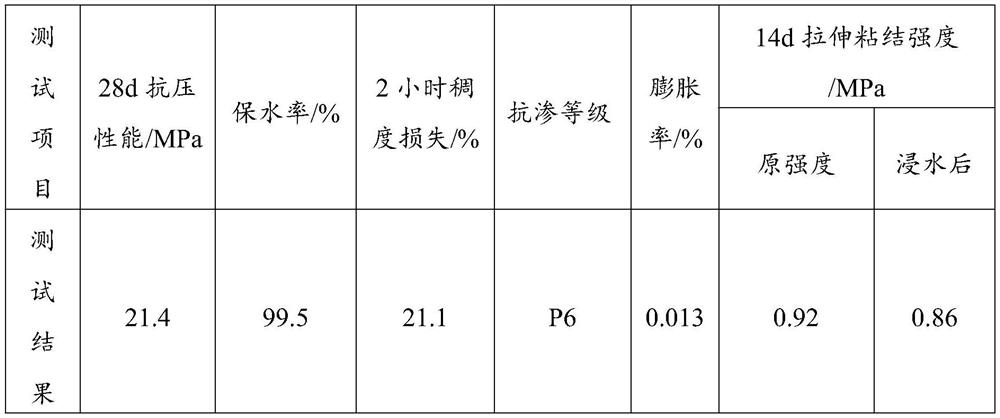

[0036] According to JGJ / T70-2009 "Standard for Test Methods of Basic Properties of Building Mortar", various performance tests were carried out, and the results are shown in Table 2.

[0037] Table 2 embodiment 1 mortar performance test result

[0038]

Embodiment 2

[0040] The coal gangue is crushed with an impact crusher, screened and classified with 40 mesh, 70 mesh, and 140 mesh square hole screens, the particle size of aggregate 1 is less than or equal to 40 mesh and greater than 70 mesh, and the particle size of aggregate 2 is less than or equal to 70 mesh is greater than or equal to 140 mesh, and below 140 mesh is stone powder. Mix Aggregate 1, Aggregate 2, ordinary Portland cement, slaked lime, fly ash, stone powder, redispersible latex powder, cellulose, and starch ether according to the parts by mass in Table 3.

[0041] Table 3 embodiment 2 each material adds mass parts

[0042]

[0043] According to JGJ / T70-2009 "Standard for Test Methods of Basic Properties of Building Mortar", various performance tests were carried out, and the results are shown in Table 4.

[0044] Table 4 embodiment 2 mortar performance test result

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com