Efficient heat increasing type compost self-heating particles as well as preparation method and application thereof

A heat-increasing, self-heating technology, applied in the preparation and application of organic fertilizers, other household appliances, etc., can solve the problems of long fermentation period and short duration of fermentation high temperature period, achieve accelerated decomposition and mineralization, and maintain high temperature Reaction time, effect of enhanced activity of thermophilic microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

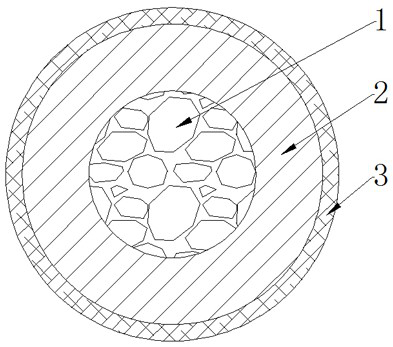

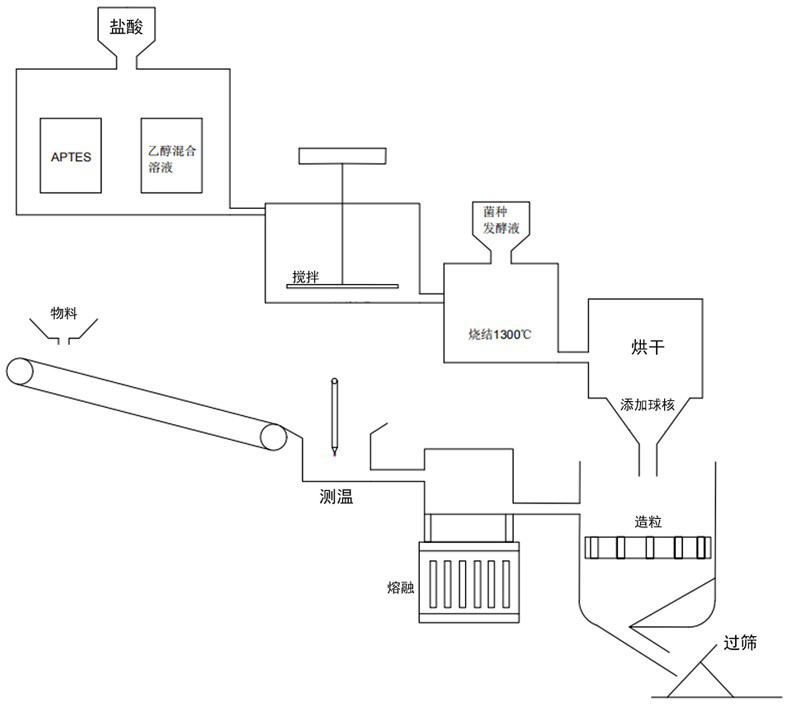

[0052] A high-efficiency heat-increasing compost self-heating particle, the core is a porous ceramic core, the outer wrapping shell of the core porous ceramic core, and the outer coating of the shell is coated with a film layer, and the particle size of the self-heating particle is 6 -10mm, with a total weight of 3g, wherein: the composition and weight ratio of the self-heating particles are as follows: 5 parts of NdFeB magnetic powder, 90 parts of biochar, 2 parts of cement, 40 parts of mesophilic bacteria agent, facultative 40 parts of thermophilic bacteria agent, 40 parts of modified pore-forming agent, 5 parts of gelling agent, 2 parts of coating material and 8 parts of kaolin base material, 0.015g for each part.

[0053] Further, the biochar is the product of the pyrolysis of the residual sludge of the sewage plant;

[0054] The cement is a mixed solution composed of acid-precipitated lignin and wood vinegar;

[0055] The mesophilic bacterial agent is a mesophilic bacter...

Embodiment 2

[0085] A high-efficiency heat-increasing compost self-heating particle, the core is a porous ceramic core, the outer wrapping shell of the core porous ceramic core, and the outer coating of the shell is coated with a film layer, and the particle size of the self-heating particle is 6 -10mm, the total weight is about 3g, wherein: the composition and weight ratio of the self-heating particles are as follows: 9 parts of NdFeB magnetic powder, 135 parts of biochar, 3 parts of cementing agent, 60 parts of mesophilic bacteria agent, and 60 parts of thermophilic bacteria agent, 60 parts of modified pore-forming agent, 7 parts of gelling agent, 3 parts of coating material and 11 parts of kaolin base material, 0.023g for each part.

[0086] Further, the biochar is the product of the pyrolysis of the residual sludge of the sewage plant;

[0087] The cement is a mixed solution composed of acid-precipitated lignin and wood vinegar;

[0088] The mesophilic bacterial agent is a mesophilic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com