Polydicyclopentadiene resin as well as preparation method and application thereof

A technology of polydicyclopentadiene and dicyclopentadiene, which is applied in the field of polydicyclopentadiene resin and its preparation, can solve the problems of influence on mechanical properties of materials, reduction of material strength, short reaction time, etc., so as to improve mechanical properties, Expand the scope of use and reduce the effect of monomer residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with specific examples and comparative examples.

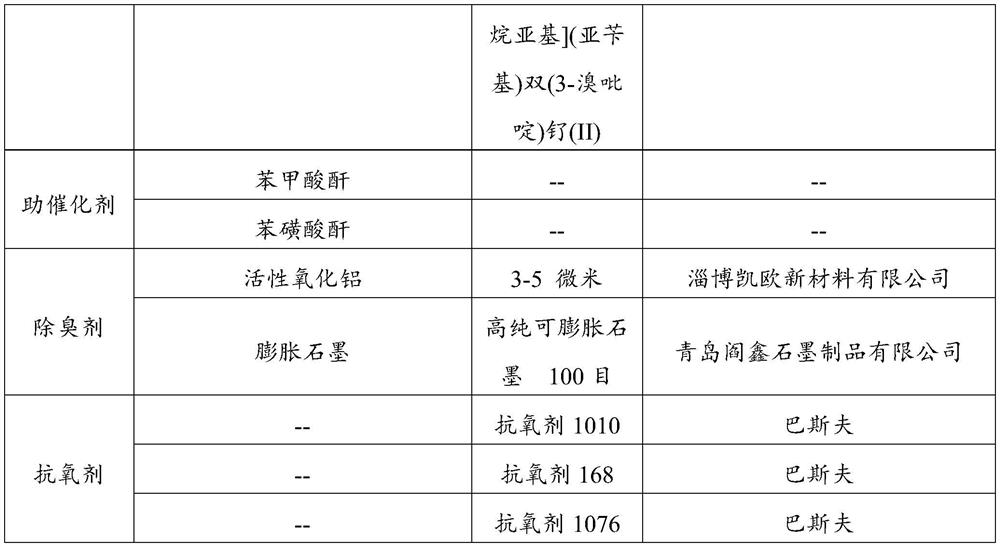

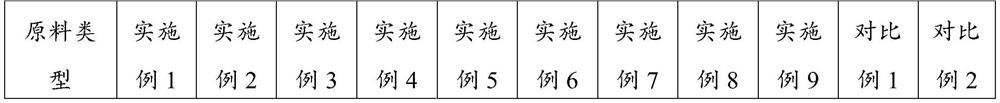

[0026] The raw material information adopted in the examples of the present invention and the comparative examples are shown in Table 1.

[0027] The raw material information of table 1 embodiment 1-9 and comparative example 1-2

[0028]

[0029]

[0030] The brominated styrene-butadiene-styrene block copolymer (brominated SBS) used in the present invention is self-made, and concrete preparation method is: earlier SBS is dissolved in the mixed solution of dichloromethane and methyl alcohol and makes Solution A, and then dissolve tetraethylammonium tribromide into a mixed solution of dichloromethane and methanol to prepare solution B, then slowly add solution B to solution A at a temperature of 10°C, and then add the catalyst tin tetrachloride. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com