High-entropy alloy film for accident fault-tolerant nuclear fuel cladding and preparation method of high-entropy alloy film

A high-entropy alloy and nuclear fuel technology, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve unfavorable fuel cladding economy, reduce coating corrosion resistance, low hardness of metal coating, etc. problems, to achieve the effect of improving resistance to high temperature water vapor oxidation, high practical performance, reducing manufacturing process complexity and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

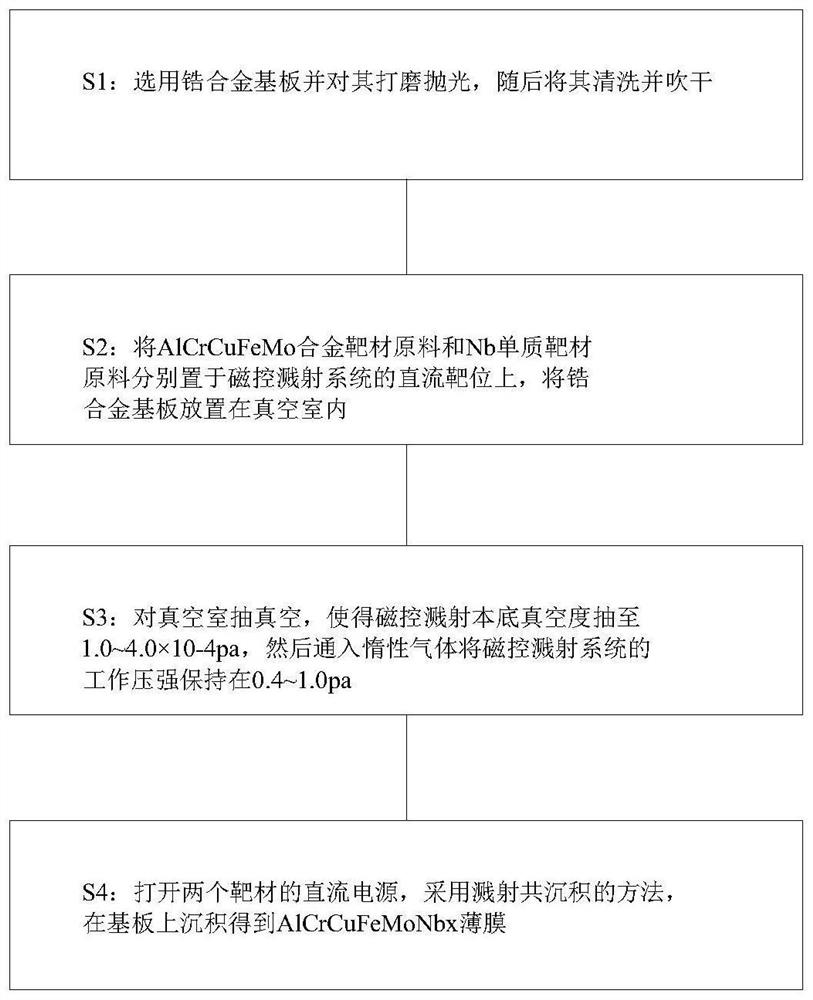

[0024] Embodiment 1: the preparation method of the high-entropy alloy film for the accident-tolerant nuclear fuel cladding, comprising the following steps:

[0025] S1: Select zirconium alloy substrate made of commercial nuclear fuel cladding zirconium alloy Zr-1Nb as raw material, use sandpaper to grind its surface to 2000# and polish to mirror surface, then put the polished substrate into acetone and alcohol for ultrasonic cleaning , and then blow dry with nitrogen;

[0026] S2: Select AlCrCuFeMo alloy target and Nb elemental target with a purity of 99.99% as raw materials, place them on the DC target position of the magnetron sputtering system, and then place the zirconium alloy substrate into the vacuum chamber;

[0027] S3: Evacuate the vacuum chamber, and evacuate the vacuum degree of the magnetron sputtering background to 1.0×10 -4 Pa, and then inert gas was introduced to keep the working pressure of the magnetron sputtering system at 0.5Pa;

[0028] S4: Turn on the D...

Embodiment 2

[0032] Embodiment 2: comprise the following steps:

[0033] S1: Select zirconium alloy substrate made of commercial nuclear fuel cladding zirconium alloy Zr-1Nb as raw material, use sandpaper to grind its surface to 2000# and polish to mirror surface, then put the polished substrate into acetone and alcohol for ultrasonic cleaning , and then blow dry with nitrogen;

[0034] S2: Select AlCrCuFeMo alloy target and Nb elemental target with a purity of 99.99% as raw materials, place them on the DC target position of the magnetron sputtering system, and then place the zirconium alloy substrate into the vacuum chamber;

[0035] S3: Evacuate the vacuum chamber, and evacuate the vacuum degree of the magnetron sputtering background to 1.0×10 -4 Pa, and then inert gas was introduced to keep the working pressure of the magnetron sputtering system at 0.5Pa;

[0036] S4: Turn on the DC power supply of the two targets, set the sputtering power of the AlCrCuFeMo target to 150W, and set the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com