Preparation method and application of organic-inorganic hybrid lead-free piezoelectric crystal

A lead-free piezoelectric and inorganic technology, applied in the field of piezoelectric materials, can solve the problems of high production cost, low piezoelectric performance, high preparation temperature, etc., and achieve the effects of low cost, improved piezoelectric performance, and excellent crystalline performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

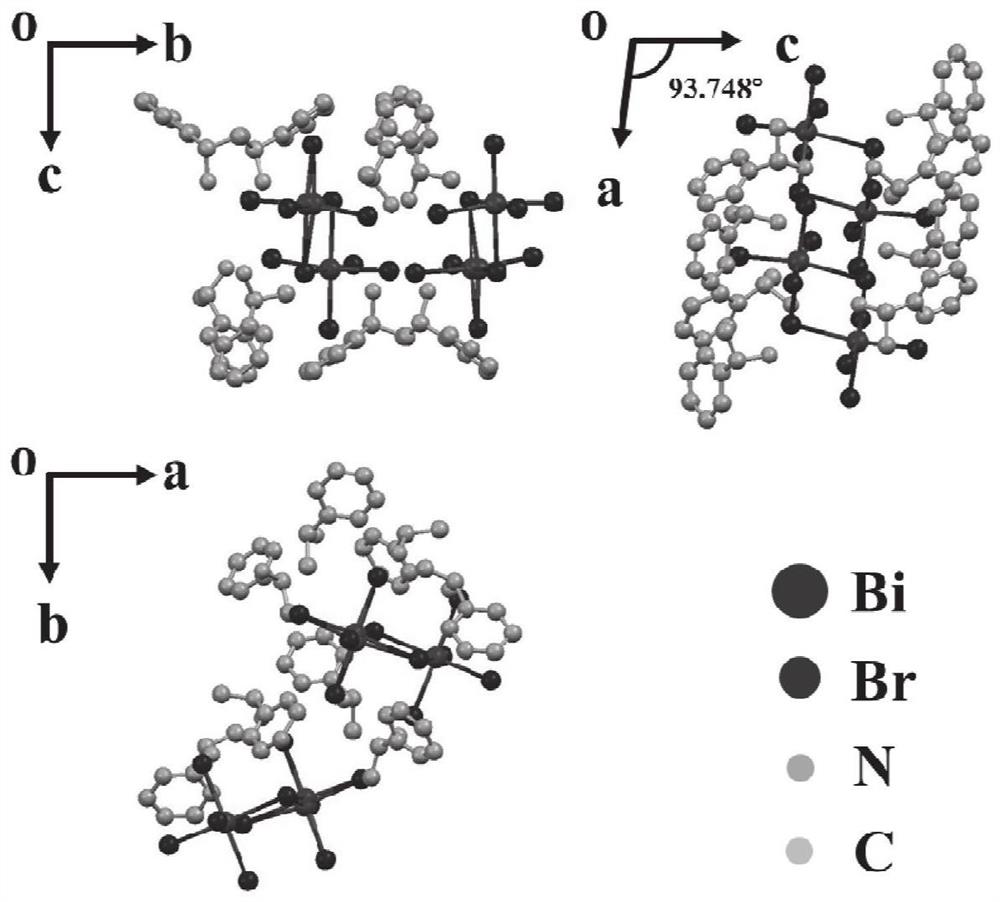

[0025] The first aspect of the present invention provides a method for preparing an organic-inorganic hybrid lead-free piezoelectric crystal, comprising the following steps: uniformly mixing bismuth oxide, hydrobromic acid and R(+)-alpha-methylbenzylamine in an oven The organic-inorganic hybrid lead-free piezoelectric crystal can be prepared by carrying out two temperature-lowering processes after medium heating.

[0026] In a typical implementation, after the temperature is raised to 90-120° C., the temperature is lowered, and the temperature is lowered to 35-50° C. to prepare an organic-inorganic hybrid lead-free piezoelectric crystal.

[0027] In a typical implementation, the molar ratio of the bismuth oxide powder to R(+)-alpha-methylbenzylamine is (0.3-0.6):(0.7-1.2), preferably 0.5:1.

[0028] In a typical implementation, the ratio of the volume of the hydrobromic acid solution to the mass of the bismuth oxide powder is (10.56-14.32) ml: (0.5-1.3) g, preferably 11.45 ml:...

Embodiment 1

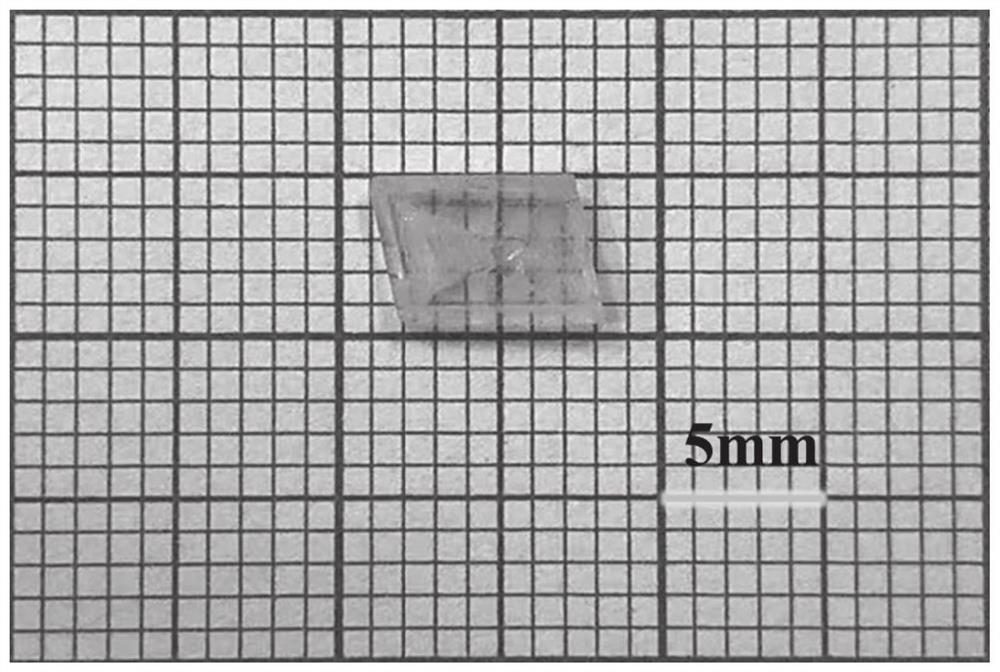

[0039]Weigh 3.4947g of bismuth oxide powder and pour it into a 100ml wide-mouth glass bottle, measure 40ml of hydrobromic acid solution, pour it into the wide-mouth bottle and cover it, and use a pipette to draw 1.92ml of R(+)-alpha-formazan benzylamine, add to the jar and cap it promptly. Put the jar into a programmed temperature-controlled oven and set the heating and cooling program: it takes 4 hours to rise from ambient temperature to 100°C, keep at 100°C for 2 hours, cool down from 100°C to 50°C, and take 24 hours to cool from 50°C to 40°C It took 48 hours, and then the temperature was maintained at 40°C. After the temperature of the oven was stabilized at 40°C, the jar was taken out, and a yellow transparent massive object was precipitated at the bottom of the bottle, which was an organic-inorganic hybrid lead-free piezoelectric crystal. The crystals were fished out and washed 4 times with n-hexane.

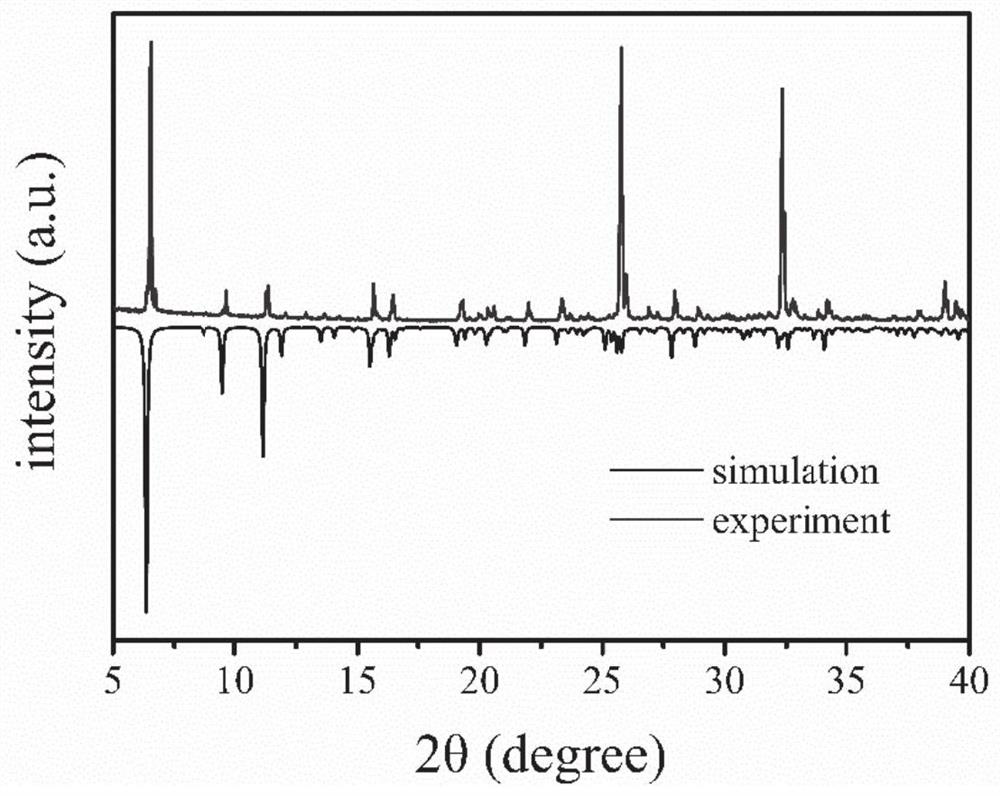

[0040] Table 1 below shows the unit cell parameters of the crystal p...

Embodiment 2

[0045] Weigh 2.5732g of bismuth oxide powder and pour it into a 100ml wide-mouth glass bottle, measure 54ml of hydrobromic acid solution, pour it into the wide-mouth bottle and cover it, and use a pipette to draw 2.32ml of R(+)-alpha-formazan benzylamine, add to the jar and cap it promptly. Put the jar into a programmed temperature-controlled oven, and set the heating and cooling program: it takes 3.5 hours to rise from ambient temperature to 95°C, keep at 95°C for 2.5 hours, cool down from 95°C to 55°C, and take 22 hours to cool from 55°C to It takes 48 hours at 35°C, and then maintains the temperature at 35°C. After the temperature of the oven was stabilized at 35°C, the jar was taken out, and a yellow transparent massive object was precipitated at the bottom of the bottle, which was an organic-inorganic hybrid lead-free piezoelectric crystal. The crystals were fished out and washed 4 times with n-hexane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com