Platinum-carbon catalyst as well as preparation method and application thereof

A platinum-carbon catalyst and carbon material technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of reduced catalytic performance of platinum meter, low catalytic activity, uneven dispersion of platinum nanoparticles, etc., to improve catalytic activity and its The effect of stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] A preparation method of platinum carbon catalyst, comprising:

[0074] (1) The step of manufacturing sulfur-doped conductive carbon black: mixing conductive carbon black with elemental sulfur, raising the temperature to 400°C-1500°C under an inert atmosphere, and then treating at a constant temperature for 0.5h-10h to obtain sulfur-doped conductive carbon black;

[0075] (2) Using the sulfur-doped conductive carbon black obtained in (1) as a carrier to support platinum.

[0076] According to the preparation method of the platinum-carbon catalyst of the present invention, the mass ratio of the conductive carbon black to sulfur is 20:1-2:1; preferably 10:1-4:1, more preferably 8:1-4:1.

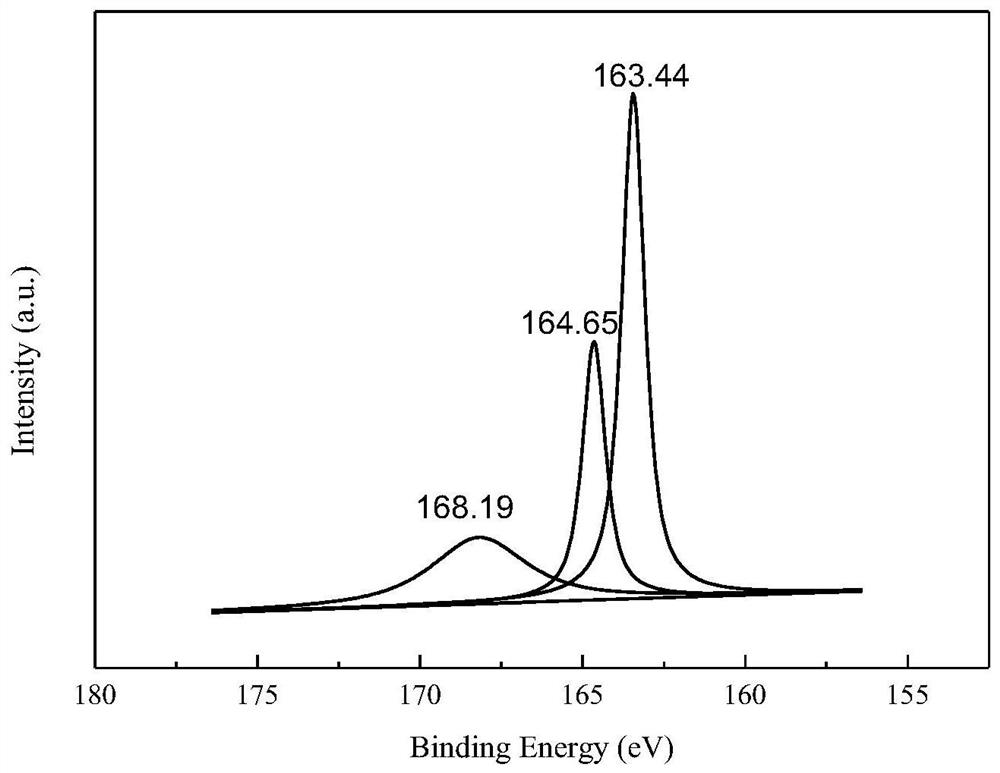

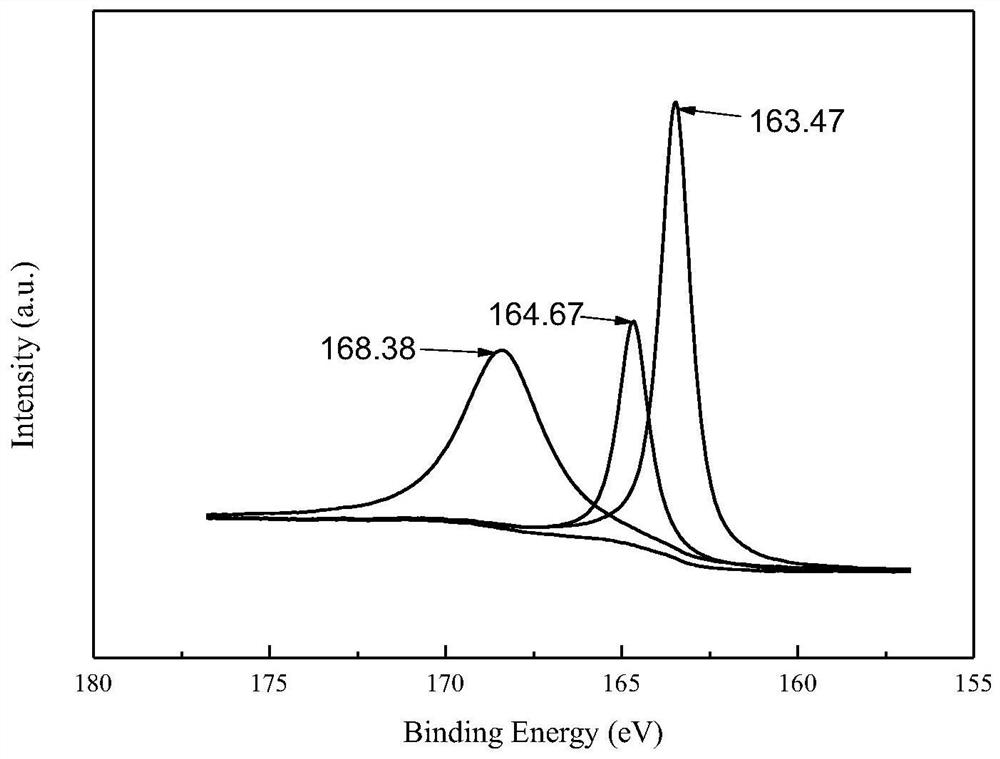

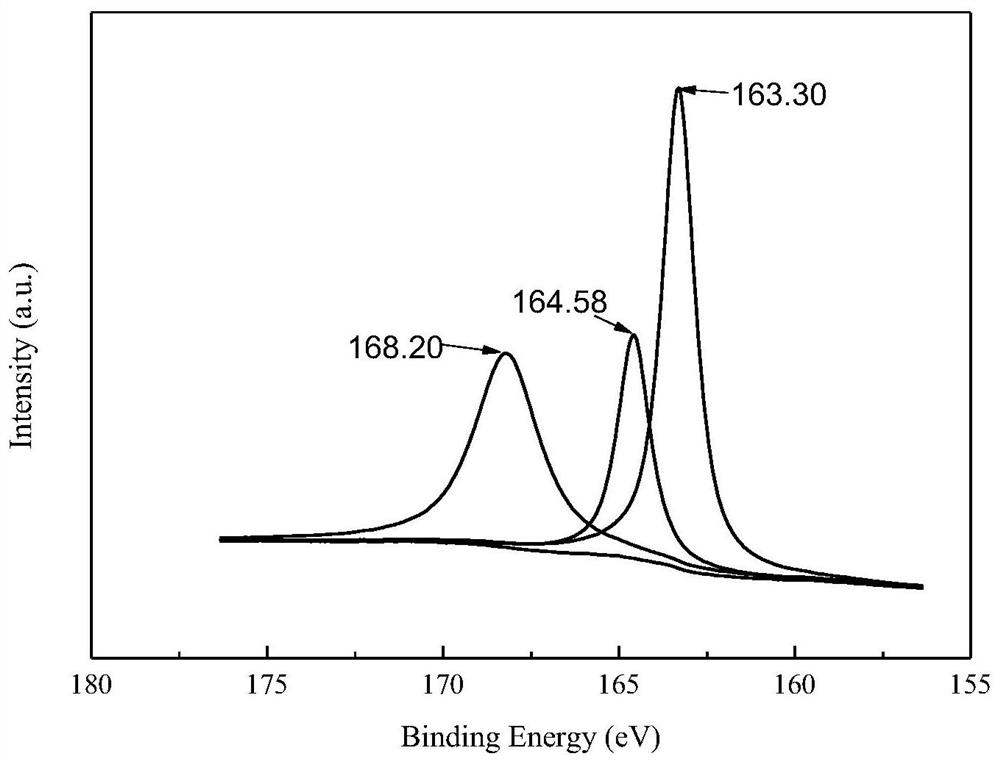

[0077] According to the preparation method of platinum-carbon catalyst of the present invention, the sulfur-doped conductive carbon black described in (1), in its XPS analyzed S 2P Among the spectral peaks, there are only characteristic peaks of thiophene sulfur between 162ev and 166ev, ...

Embodiment 1

[0132] This example is used to illustrate the preparation of the sulfur-doped carbon support of the present invention.

[0133] Mix Ketjenblack ECP600JD and elemental sulfur evenly, the mass ratio of the two is 4:1, put it in a tube furnace, raise the temperature of the tube furnace to 1000 °C at a rate of 5 °C / min, and then treat it at a constant temperature for 2 hours. After cooling down naturally The obtained sulfur-doped conductive carbon black is coded as carbon carrier A.

[0134] Sample Characterization and Testing

[0135] The sulfur mass fraction analyzed by XPS is 0.72%; the oxygen mass fraction analyzed by XPS is 12.7%; the specific surface area is 1373m 2 / g, the pore volume is 2.31mL / g; the resistivity is 1.38Ω·m.

Embodiment 2

[0137] This example is used to illustrate the preparation of the sulfur-doped carbon support of the present invention.

[0138] Mix Vulcan XC72 and elemental sulfur evenly, the mass ratio of the two is 6:1, put it in a tube furnace, raise the temperature of the tube furnace to 400 °C at a rate of 8 °C / min, and then treat it at a constant temperature for 3 hours. After cooling down naturally Obtain sulfur-doped conductive carbon black, coded as carbon carrier B.

[0139] Sample Characterization and Testing

[0140] The sulfur mass fraction analyzed by XPS is 1.21%; the oxygen mass fraction analyzed by XPS is 8.53%; the specific surface area is 247m 2 / g, the pore volume is 0.47mL / g; the resistivity is 1.29Ω·m.

[0141] figure 1 It is the XPS spectrogram of the carbon carrier of embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com