Recyclable cellulose-based conductive self-repairing eutectic gel as well as preparation method and application thereof

A cellulose-based, self-healing technology, applied in the direction of using electric/magnetic devices to transmit sensing components, can solve the problems of time-consuming manufacturing process, complexity, and large-scale application limitations, so as to avoid structural damage and self-healing The effect of adjustable performance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

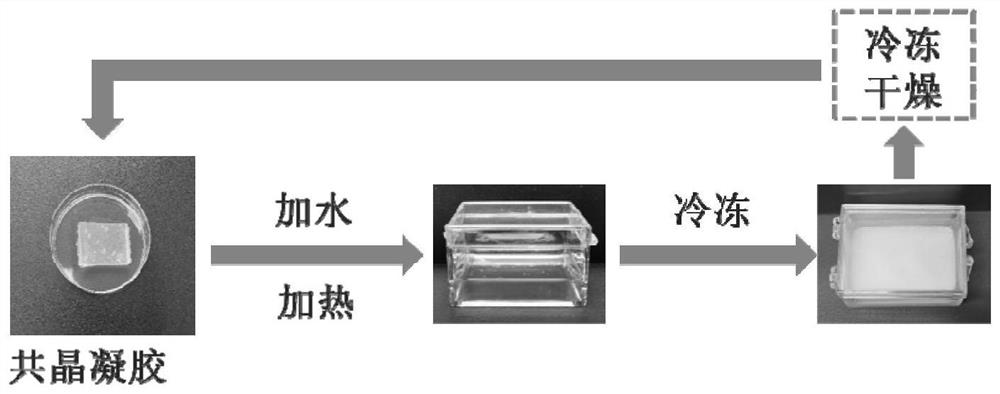

[0048] A method for preparing recyclable oriented cellulose-based conductive self-repairing eutectic gel, comprising the following steps:

[0049](1) Mix the PVA solution whose mass fraction range of PVA is 5.0wt% of System 3 with the gelatin solution whose mass fraction range of gelatin is 5.0wt% of System 3, and stir evenly to obtain System 1.

[0050] (2) Glycerol-choline chloride with a molar ratio of 3:1 was configured as DES, and 30 wt% of DES whose mass fraction range was System 3 was added to System 1, and stirred evenly to obtain System 2.

[0051] (3) Add 2.0wt% DCMC whose mass fraction is System 3 to System 2, and stir evenly to obtain System 3.

[0052] (4) Pour system 3 into a mold for directional freezing with liquid nitrogen, and after 3 directional freezing-thawing operations, system 4 is obtained.

[0053] (5) Freeze-drying the system 4 to obtain a recyclable oriented cellulose-based conductive self-healing eutectic gel.

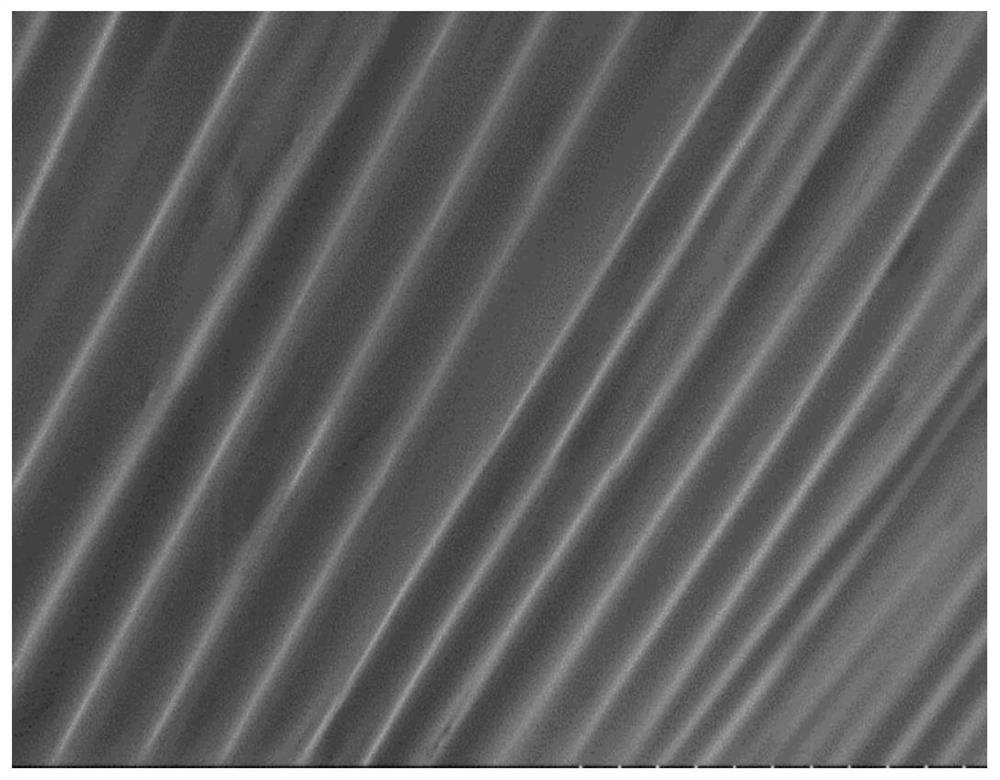

[0054] figure 2 It is a scanning ...

Embodiment 2

[0057] A method for preparing recyclable oriented cellulose-based conductive self-repairing eutectic gel, comprising the following steps:

[0058] (1) Mix the PVA solution whose mass fraction range of PVA is 2.5wt% of System 3 with the gelatin solution whose mass fraction range of gelatin is 5.0wt% of System 3, and stir evenly to obtain System 1.

[0059] (2) Glycerol-choline chloride with a molar ratio of 3:1 was configured as DES, and 30 wt% of DES whose mass fraction range was System 3 was added to System 1, and stirred evenly to obtain System 2.

[0060] (3) Add 2.0wt% DCMC whose mass fraction is System 3 to System 2, and stir evenly to obtain System 3.

[0061] (4) Pour system 3 into a mold for directional freezing with liquid nitrogen, and after 3 directional freezing-thawing operations, system 4 is obtained.

[0062] (5) Freeze-drying the system 4 to obtain a recyclable oriented cellulose-based conductive self-healing eutectic gel.

Embodiment 3

[0064] A method for preparing recyclable oriented cellulose-based conductive self-repairing eutectic gel, comprising the following steps:

[0065] (1) Mix the 10.0wt% PVA solution whose mass fraction range of PVA is System 3 and the 5.0wt% gelatin solution whose mass fraction range is System 3, and stir evenly to obtain System 1.

[0066] (2) Glycerol-choline chloride with a molar ratio of 3:1 was configured as DES, and 30 wt% of DES whose mass fraction range was System 3 was added to System 1, and stirred evenly to obtain System 2.

[0067] (3) Add 2.0wt% DCMC whose mass fraction is System 3 to System 2, and stir evenly to obtain System 3.

[0068] (4) Pour system 3 into a mold for directional freezing with liquid nitrogen, and after 3 directional freezing-thawing operations, system 4 is obtained.

[0069] (5) Freeze-drying the system 4 to obtain a recyclable oriented cellulose-based conductive self-healing eutectic gel.

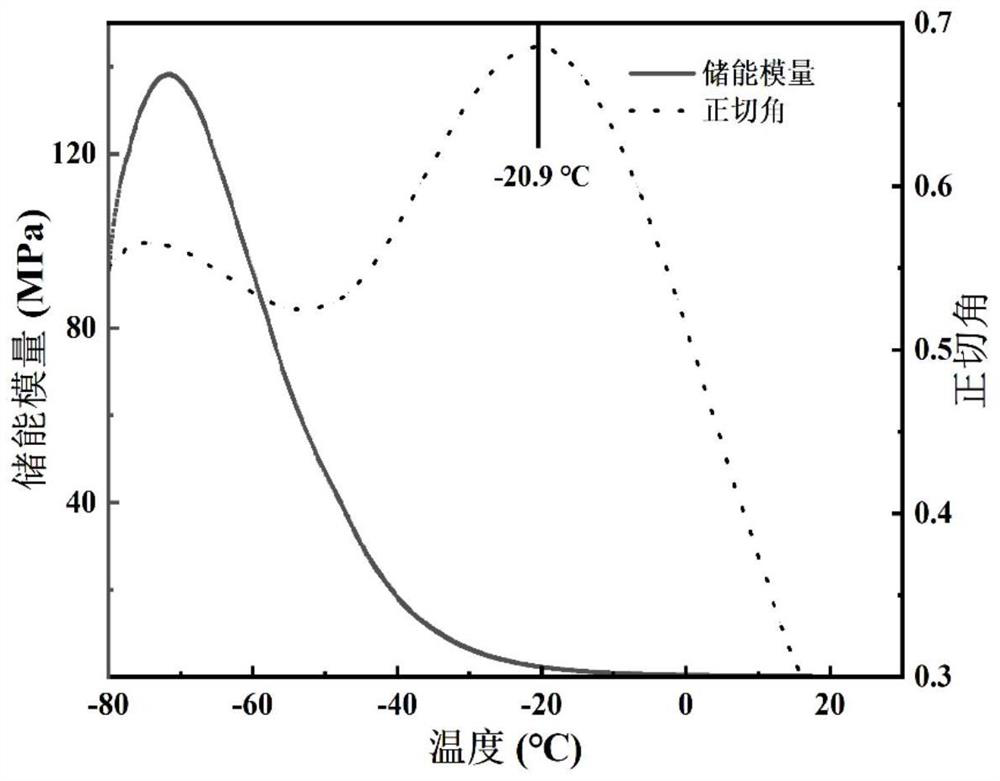

[0070] Figure 4 and Figure 5 Respectively, in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com