Bioactive protein feed and processing device thereof

A bioactive protein and feed processing technology, which is applied in the field of bioactive protein feed and its processing equipment, can solve the problems of cumbersome discharging and mixing operations, low utilization rate, long preparation cycle, etc., and achieve a scientific overall structure design, The effect of reducing preparation cost and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

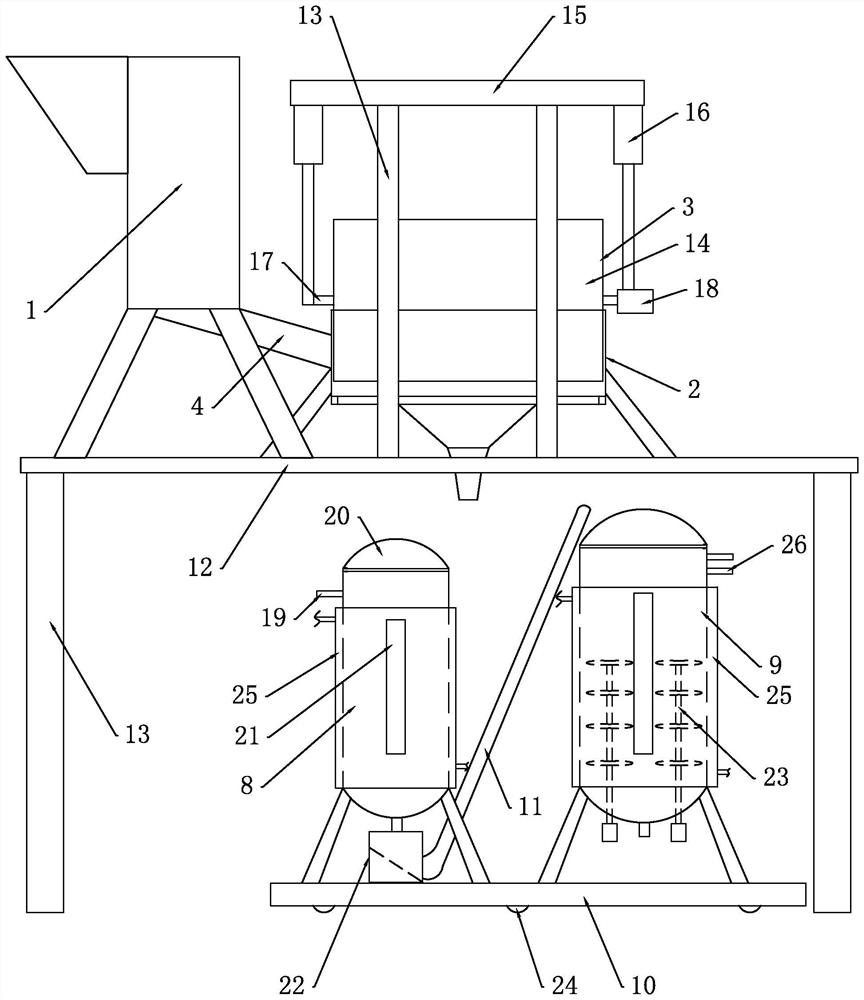

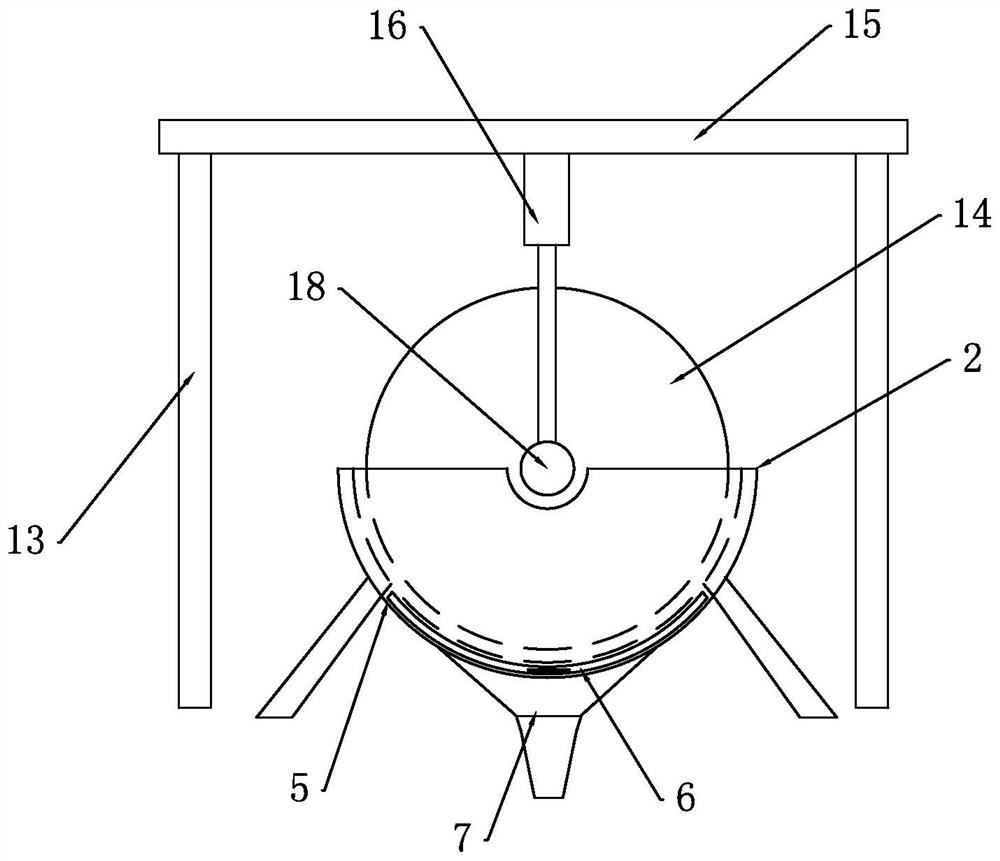

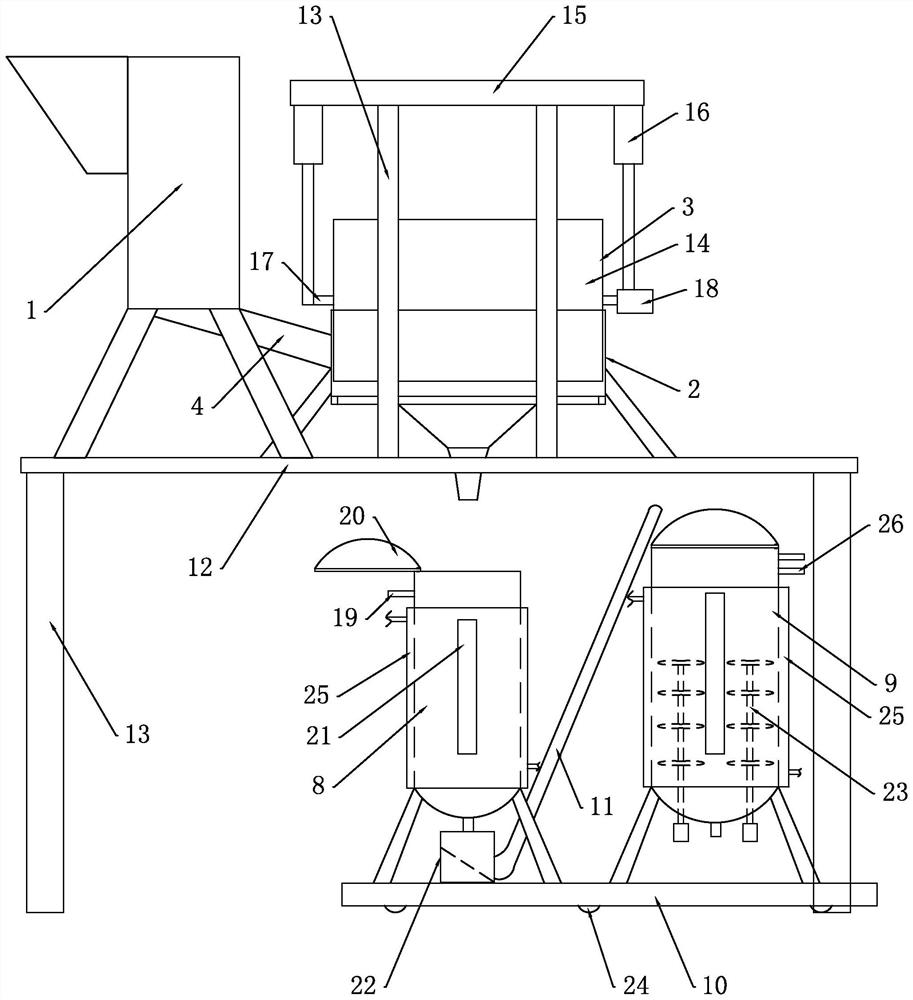

Method used

Image

Examples

Embodiment 1

[0046] A biologically active protein feed made from ingredients by weight of:

[0047] Fermented soybean meal 230Kg, rice bran 200Kg, marine bioactive protein components 10Kg, soybean oil 25Kg, salt 2Kg, compound fermented fungi 0.3Kg, corn flour 180Kg, stone powder 15Kg;

[0048] Wherein, the marine bioactive protein component is made of the following raw materials: mussel powder 200Kg, starfish 220Kg, kelp 125Kg, wakame 65Kg.

[0049] The above-mentioned compound fermentation fungus is a mixed fungus of Bacillus subtilis, plant lactic acid bacteria and Bacillus licheniformis. Bacillus subtilis ≥ 1.00*10 per part by weight of compound fermentation bacteria 13 CFU, plant lactic acid bacteria ≥1.00*10 11 CFU and Bacillus licheniformis ≥1.00*10 12 CFU.

[0050] The preparation method of above-mentioned bioactive protein feed comprises the steps:

[0051] (1) Preparation of marine bioactive protein components: select raw mussels, boil and shell them, dehydrate and dry the mu...

Embodiment 2

[0069] A biologically active protein feed made from ingredients by weight of:

[0070] Fermented soybean meal 200Kg, rice bran 220Kg, marine bioactive protein components 5Kg, soybean oil 20Kg, salt 1Kg, compound fermented fungi 0.4Kg, corn flour 120Kg, stone powder 10Kg;

[0071] Wherein, the marine bioactive protein component is made of the following raw materials: mussel powder 150Kg, starfish 200Kg, kelp 100Kg, wakame 50Kg;

[0072] The composite fermentation fungus is a mixed fungus composed of bacillus subtilis, plant lactic acid bacteria and bacillus licheniformis.

[0073] The preparation method of the above bioactive protein feed is the same as the preparation method of Example 1, except that step (2) fermentation temperature is 32° C.; step (4) fermentation temperature is 35° C., and fermentation is 30 h.

[0074] The processing device is the same as that in Example 1.

Embodiment 3

[0076] A biologically active protein feed made from ingredients by weight of:

[0077] Fermented soybean meal 250Kg, rice bran 160Kg, marine bioactive protein components 15Kg, soybean oil 30Kg, salt 1Kg, compound fermented fungi 0.4Kg, corn flour 240Kg, stone powder 20Kg;

[0078] Wherein, the marine bioactive protein component is made of the following raw materials: mussel powder 300Kg, starfish 250Kg, kelp 150Kg, wakame 80Kg;

[0079] The composite fermentation fungus is a mixed fungus composed of bacillus subtilis, plant lactic acid bacteria and bacillus licheniformis.

[0080] The preparation method is the same as the preparation method of Example 1, except that step (2) fermentation temperature is 33° C.; step (4) fermentation temperature is 30° C., and fermentation is 48 hours.

[0081] The processing device is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com