Ti-Al-Nb based composite material and preparation method thereof

A technology of ti-al-nb and composite materials, which is applied in the field of Ti-Al-Nb-based composite materials and its preparation, can solve the problems of poor reinforcement distribution uniformity, large deformation resistance, and reduced reinforcement benefits, and achieve process stability Controllable, heat-strength performance improvement, excellent enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

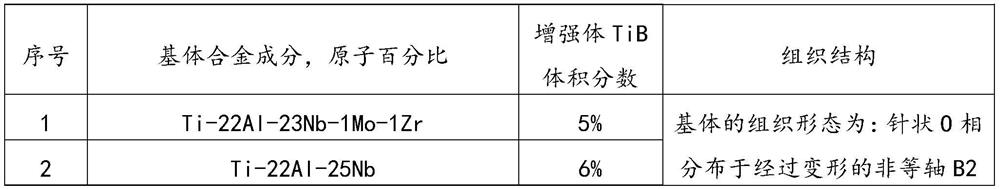

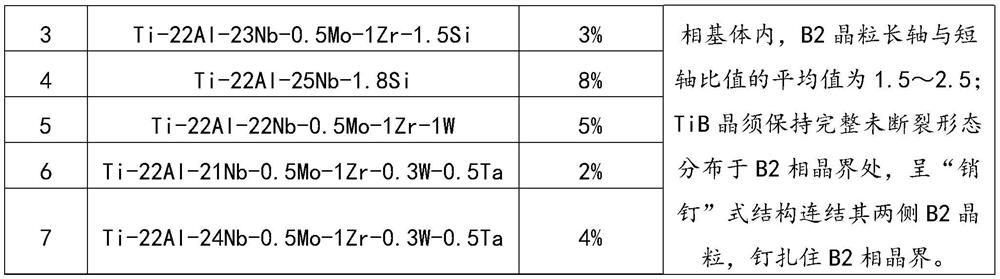

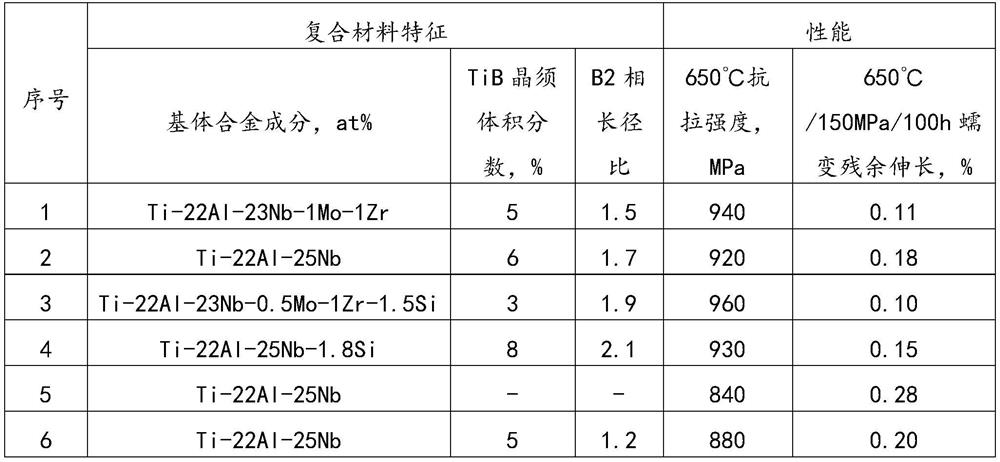

Examples

Embodiment 1

[0027] 1. Spherical Ti-22Al-23Nb-1Mo-1Zr powder and B powder are mixed and ball milled, the weight ratio of B in the mixed powder is 1.33%, the weight ratio of ball and material is 3:1, the ball milling time is 10h, and the speed is 150r / min , preparing a composite structure powder in which the B powder wraps the surface of the spherical Ti-Al-Nb powder;

[0028] 2. Put the composite structure powder obtained in step 1 into a rubber sheath, vacuumize and seal to obtain a soft sheath structure of the composite structure powder;

[0029] 3. The soft sheath structure obtained in step 2 is prefabricated and densified by isostatic pressing at room temperature, the pressure is 400 MPa, the pressure is kept for 2 hours, and the sheath is removed to obtain a semi-dense preform;

[0030] 4. Put the semi-dense preform obtained in step 3 into a red copper hard sheath, vacuumize and seal it to obtain the hard sheath structure of the composite powder preform;

[0031] 5. Warm deformation of...

specific Embodiment 2

[0034] 1. Spherical Ti-22Al-25Nb powder and TiB 2 Powder mixed ball milling, TiB in mixed powder 2 The weight ratio of the powder is 2.56%, the weight ratio of the ball and the material is 5:1, the ball milling time is 15h, and the rotation speed is 200r / min, and the composite structure powder with TiB2 powder wrapped on the surface of the spherical Ti-Al-Nb powder is prepared;

[0035] 2. Put the composite structure powder obtained in step 1 into a rubber sheath, vacuumize and seal to obtain a soft sheath structure of the composite structure powder;

[0036] 3. The soft sheath structure obtained in step 2 is prefabricated and densified by isostatic pressure at room temperature, the pressure is 400 MPa, the pressure is kept for 3 hours, and the sheath is removed to obtain a semi-dense preform;

[0037] 4. Put the semi-dense preform obtained in step 3 into a red copper hard sheath, vacuumize and seal it to obtain the hard sheath structure of the composite powder preform;

[0...

specific Embodiment 3

[0041] 1. Spherical Ti-22Al-23Nb-0.5Mo-1Zr-1.5Si powder and TiB2 powder are mixed and ball milled, the weight ratio of TiB2 in the mixed powder is 4.17%, the weight ratio of ball and material is 7:1, and the ball milling time is 20h. The rotation speed is 300r / min, and the composite structure powder in which the B powder wraps the surface of the spherical Ti-Al-Nb powder is prepared;

[0042] 2. Put the composite structure powder obtained in step 1 into a plastic sheath, vacuumize and seal it to obtain a soft sheath structure of the composite structure powder;

[0043] 3. The soft sheath structure obtained in step 2 is prefabricated and densified by isostatic pressure at room temperature, the pressure is 400 MPa, the pressure is kept for 3 hours, and the sheath is removed to obtain a semi-dense preform;

[0044] 4. Put the semi-dense preform obtained in step 3 into a stainless steel hard cover, vacuumize and seal it, and obtain the hard cover structure of the composite powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com