Manufacturing method of semiconductor structure and semiconductor structure

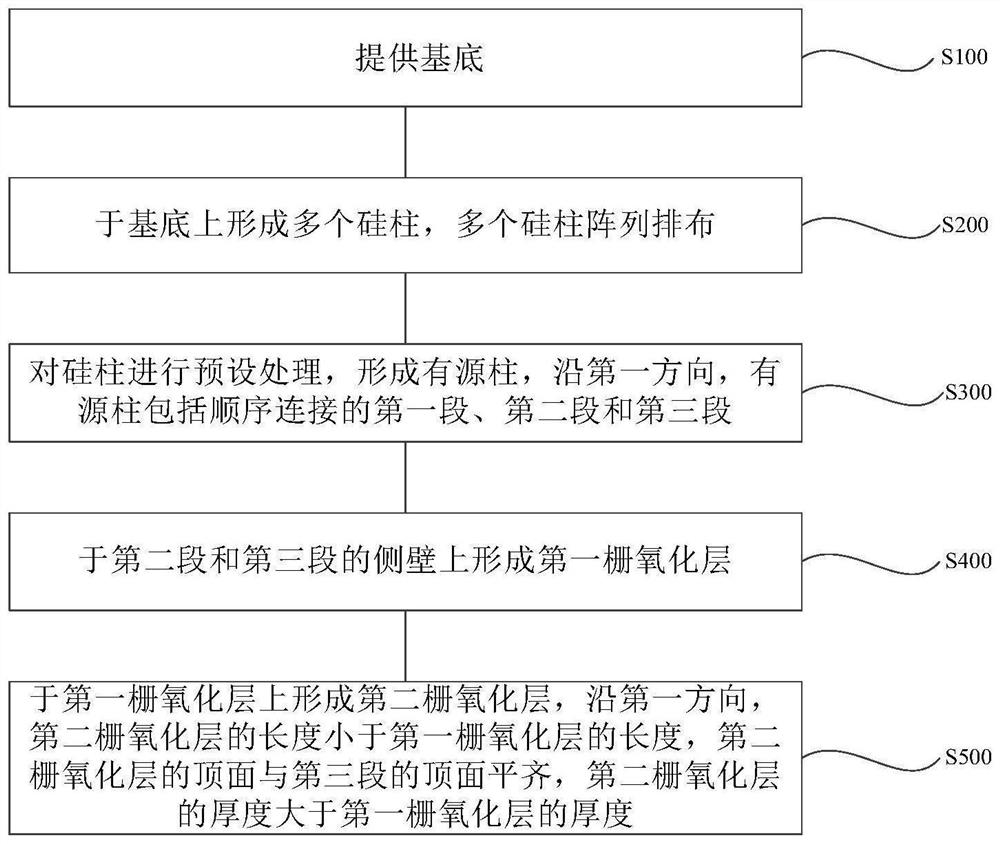

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, transistors, etc., can solve the problems of reducing semiconductor structure performance and yield, leakage, etc., to reduce leakage current, control shutdown current, improve performance and good rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

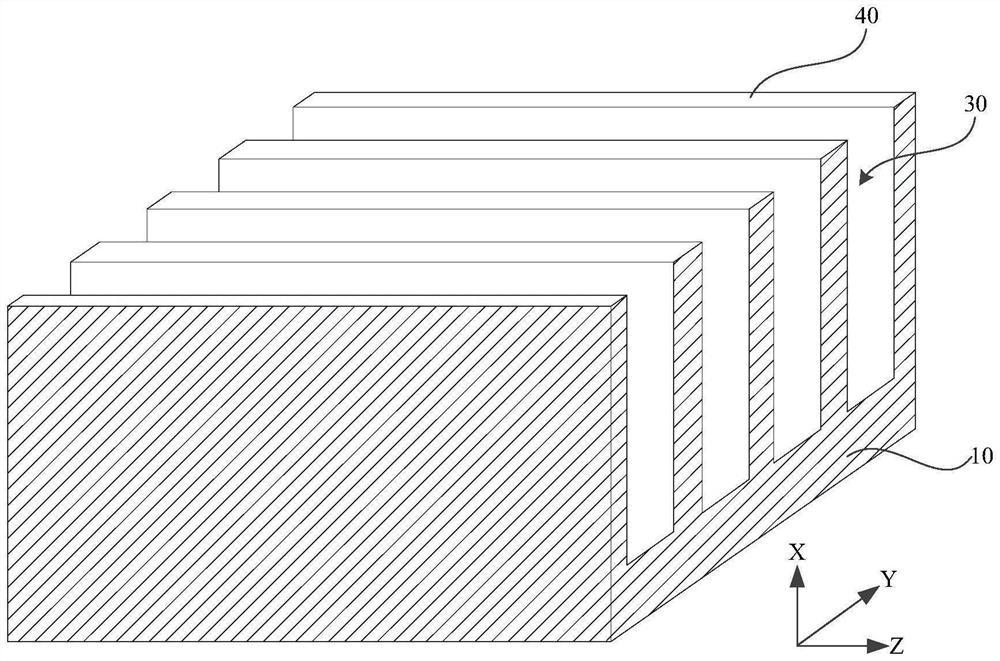

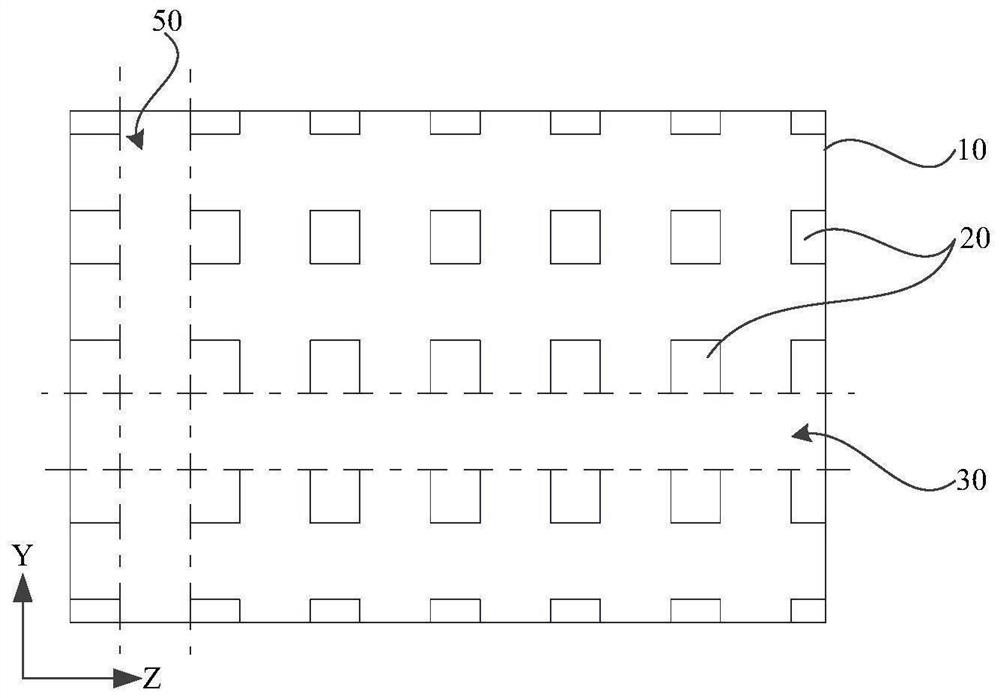

[0089] In order to make the purpose, technical solutions and advantages of the embodiments of the present disclosure clearer, the technical solutions in the disclosed embodiments will be clearly and completely described below in conjunction with the drawings in the embodiments of the present disclosure. Obviously, the described embodiments It is a part of the embodiments of the present disclosure, but not all of them. Based on the embodiments in the present disclosure, all other embodiments obtained by those skilled in the art without making creative efforts belong to the protection scope of the present disclosure. It should be noted that, in the case of no conflict, the embodiments in the present disclosure and the features in the embodiments can be combined arbitrarily with each other.

[0090] Dynamic random access memory (DRAM for short) is a semiconductor memory capable of writing and reading data at high speed and randomly, and is widely used in data storage devices or d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com