Carbon nitride nanosheet-gold nanoparticle composite material as well as preparation method and application thereof

A gold nanoparticle and composite material technology, which is applied in the field of carbon nitride nanosheet-gold nanoparticle composite material and its preparation, can solve the problems of inability to carry out large-scale industrial application, difficult separation of products, high energy consumption, etc., and meet the reaction conditions Ease of control, easy separation of products, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A carbon nitride nanosheet-gold nanoparticle composite material, the preparation method of which comprises the following steps:

[0041] 1) Add 15g of ammonium chloride and 3g of dicyandiamide into 100mL of ultrapure water, stir in a sand bath at 80°C for 4h, then place in an oven, dry at 100°C for 48h, grind and place in a horse In a Furnace, heat at 550°C for 4h to obtain a calcined product (yellow solid);

[0042] 2) Grind 0.13 g of the calcined product and disperse it in ultrapure water, prepare it into a dispersion with a concentration of 1 mg / mL, ultrasonically crush it for 1 h, then add 1.47 mL of a chloroauric acid solution with a concentration of 25 mmol / L while stirring. Under the irradiation of full-band xenon lamp, reacted for 4h, filtered, and the filtered solid was washed and dried to obtain carbon nitride nanosheet-gold nanoparticle composite material (Au / g-C 3 N 4 ).

[0043] Performance Testing:

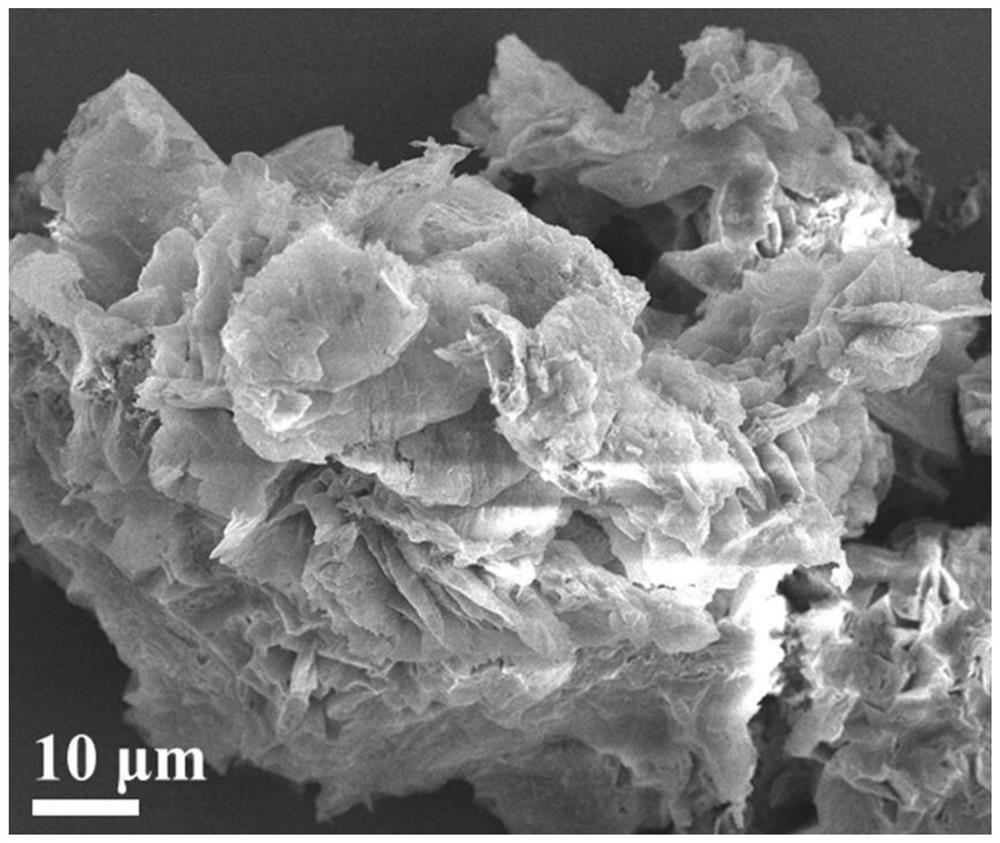

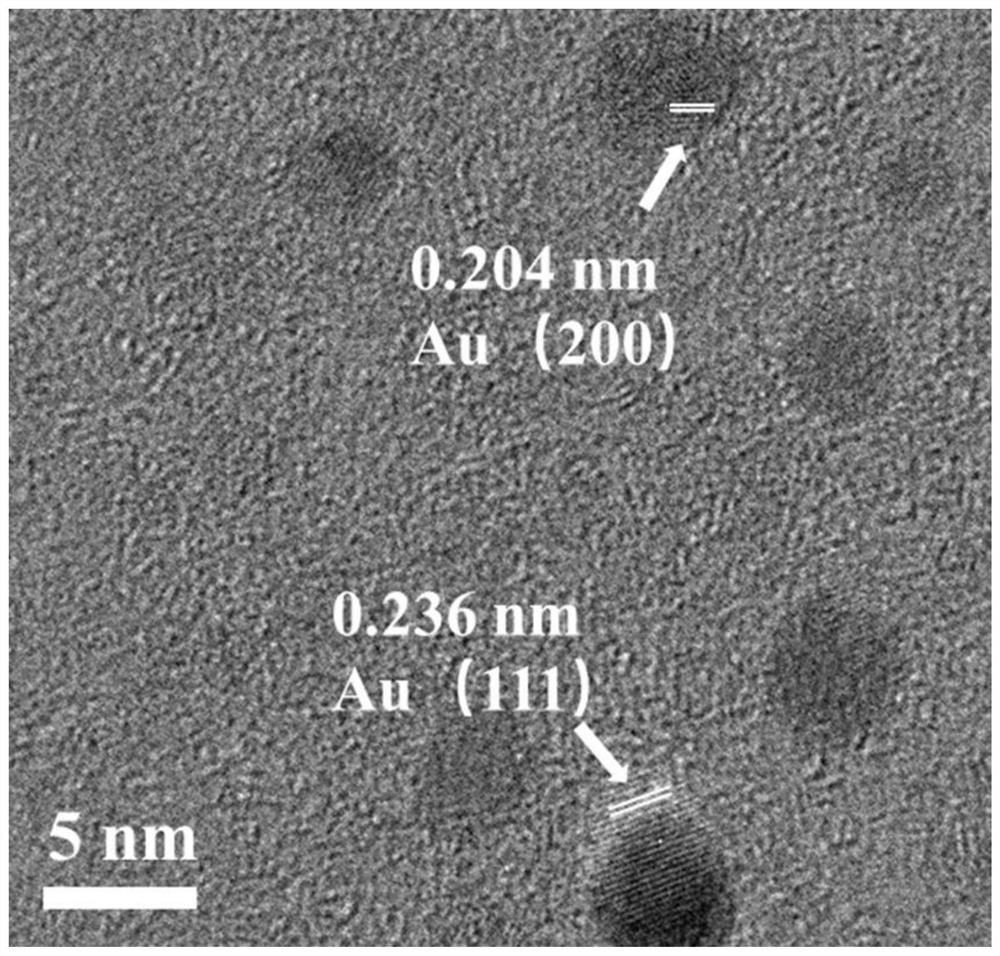

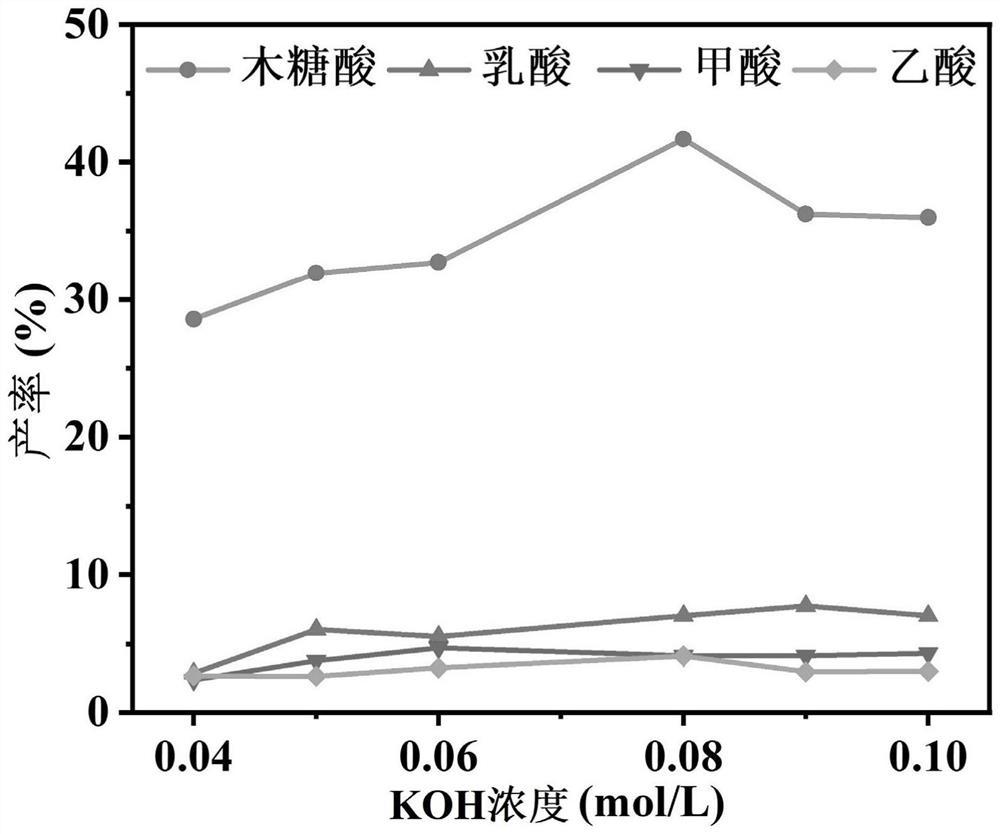

[0044] Au / g-C of this embodiment 3 N 4 The scannin...

Embodiment 2

[0048] A carbon nitride nanosheet-gold nanoparticle composite material, the preparation method of which comprises the following steps:

[0049] 1) Add 15g of ammonium chloride and 3g of dicyandiamide into 100mL of ultrapure water, stir in a sand bath at 80°C for 4h, then place in an oven, dry at 100°C for 48h, grind and place in a horse In a Furnace, heat at 550°C for 4h to obtain a calcined product (yellow solid);

[0050] 2) Grind 0.11 g of the calcined product and disperse it in ultrapure water, prepare a dispersion with a concentration of 1 mg / mL, ultrasonically crush it for 1 h, then add 0.5 mL of a chloroauric acid solution with a concentration of 25 mmol / L while stirring. React for 4 hours under the irradiation of a full-band xenon lamp, filter, and wash the filtered solid with water and dry to obtain a carbon nitride nanosheet-gold nanoparticle composite material.

[0051] Performance Testing:

[0052] After testing, the morphological features of the carbon nitride n...

Embodiment 3

[0054]A carbon nitride nanosheet-gold nanoparticle composite material, the preparation method of which comprises the following steps:

[0055] 1) Add 15g of ammonium chloride and 3g of dicyandiamide into 100mL of ultrapure water, stir in a sand bath at 80°C for 4h, then place in an oven, dry at 100°C for 48h, grind and place in a horse In a Furnace, heat at 550°C for 4h to obtain a calcined product (yellow solid);

[0056] 2) Grind 0.13 g of the calcined product and disperse it in ultrapure water, prepare a dispersion with a concentration of 1 mg / mL, ultrasonically crush it for 1 h, then add 2.94 mL of a chloroauric acid solution with a concentration of 25 mmol / L while stirring. React for 4 hours under the irradiation of a full-band xenon lamp, filter, and wash the filtered solid with water and dry to obtain a carbon nitride nanosheet-gold nanoparticle composite material.

[0057] Performance Testing:

[0058] After testing, the morphological features of the carbon nitride n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com