Foaming ceramic plate production equipment and production process thereof

A technology for foamed ceramic plates and production equipment, which is applied in ceramic molding machines, auxiliary molding equipment, manufacturing tools, etc., can solve the problems of cracking of foamed ceramic plates, insufficient crushing and mixing, and failure to cut in time, so as to reduce damage. , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

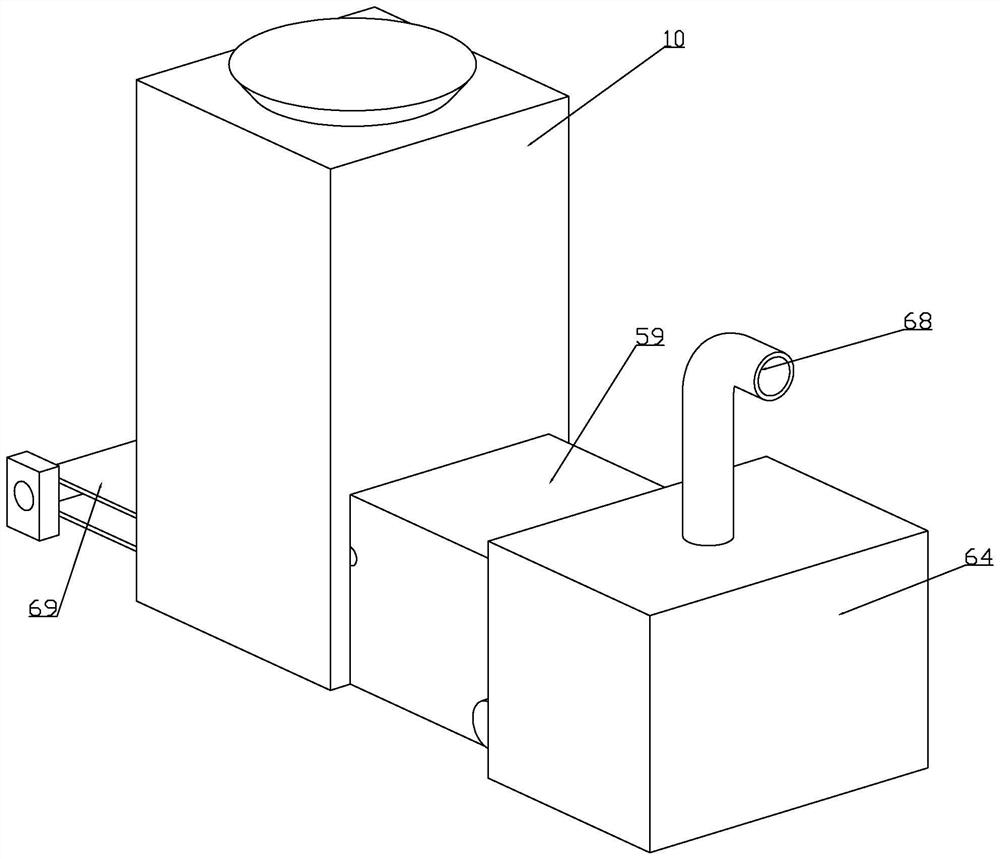

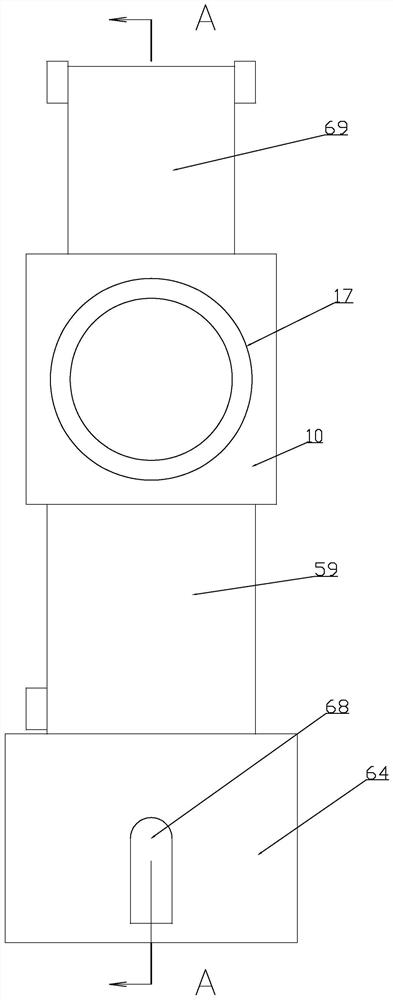

[0043] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

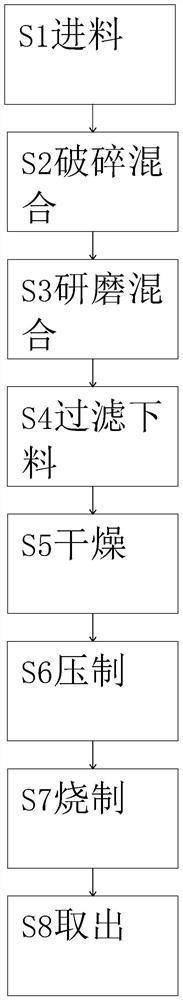

[0044] combine Figure 1-11 , a foamed ceramic plate production equipment and production process thereof, comprising the following steps:

[0045]S1: feeding, aluminum oxide, diatomaceous earth, silicon carbide, quartz sand, calcium carbonate, and kaolin are entered into the processing box through the feeding funnel;

[0046] S2: crushing and mixing, the material is fully crushed and filtered and fully mixed into mixture A;

[0047] S3: Grinding and mixing, adding foundry waste sand, nano-scale silicon micropowder, and modified graphene to the mixture A in sequence, and fully mixing and grinding to obtain the mixture B;

[0048] S4: Filtration and blanking, the mixture B is filtered and screened for blanking;

[0049] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com