A kind of silver-molybdenum electrical contact material with high dispersion degree and preparation method thereof

A technology of electrical contact materials and dispersion, applied in the direction of contacts, circuits, electric switches, etc., can solve the problems that the reinforcement phase aggregation cannot be completely eliminated, the silver and molybdenum cannot form a good combination, and the pores of the coating powder cannot be removed. , to achieve the effect of eliminating defects, improving infiltration and preventing holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

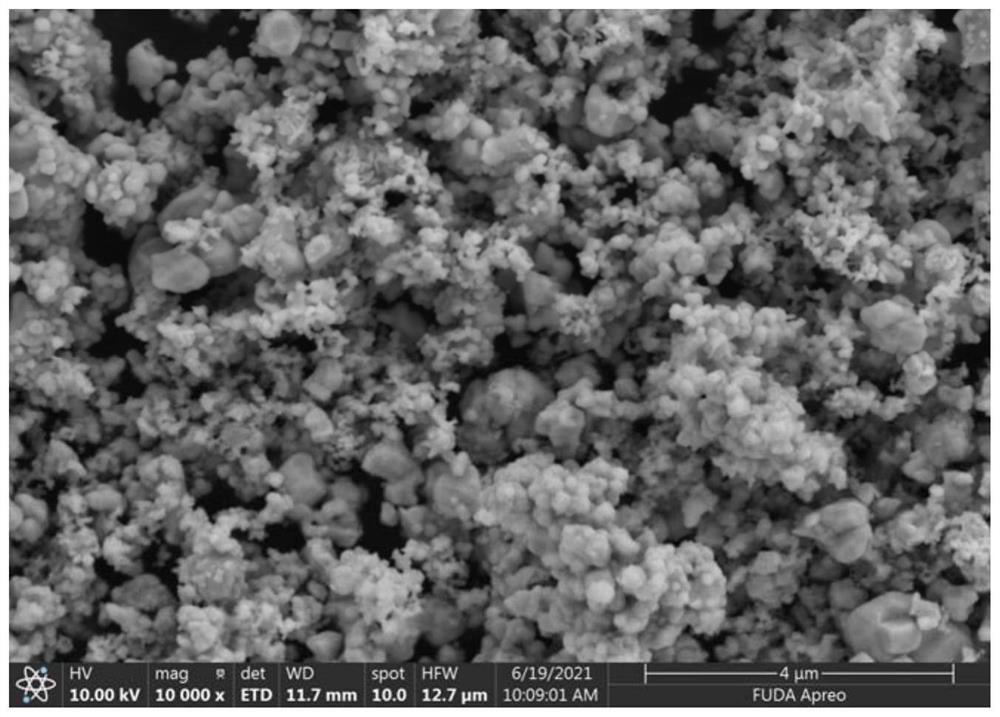

Image

Examples

Embodiment 1

[0032] A preparation method of silver-molybdenum contact material, comprising the following steps:

[0033] a. The proportion of molybdenum and additives is 98:2; the additive powder is composed of Co powder: 0.3-1.0%, nickel powder: 0.5-1.2%, copper powder: 0.1-0.3%;

[0034] b. Put the molybdenum and additives into the ball mill, the ball milling time is 10H, the rotation speed is 20 rev / min, and the ratio of ball to material is 2:1;

[0035] c, adding 3.5kg of molybdenum additive pretreatment powder and silver nitrate solution into the reaction vessel, then adding 0.015kg polyacrylic acid and an appropriate amount of deionized water to the vessel, ultrasonically and stirring for 2 hours;

[0036] d. Keep ultrasonication and stirring, gradually add hydrazine hydrate solution to the container, until the pH value of the solution reaches 8-9, keep ultrasonication and stirring for 0.5 hours;

[0037] e. Keep ultrasonication and stirring, gradually add glucose solution with a co...

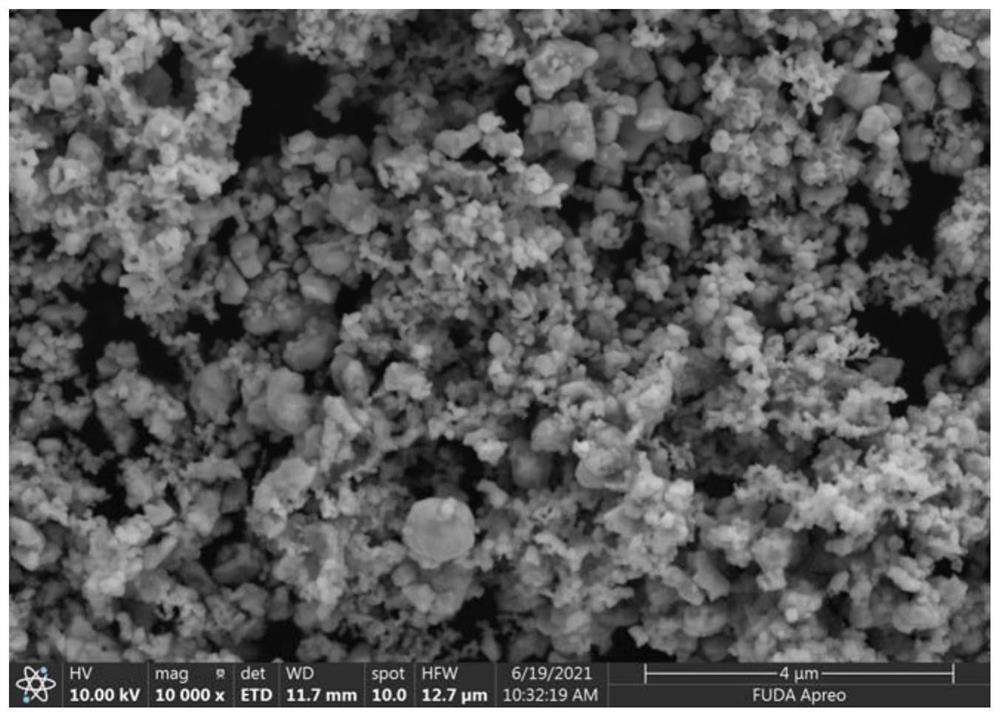

Embodiment 2

[0045] A preparation method of silver-molybdenum contact material, comprising the following steps:

[0046] a. The proportion of molybdenum and additives is 98:3, and the additive powder is composed of Co powder: 0.5-1.3%, nickel powder: 0.5-1.5%, copper powder: 0.1-0.3%;

[0047] b. Put molybdenum and additives into the ball mill, the ball milling time is 15H, the rotation speed is 40 rev / min, and the ball-to-material ratio is 5:1;

[0048]c, adding 3.5kg of molybdenum additive pretreatment powder and silver nitrate solution into the reaction vessel, then adding 0.015kg polyacrylic acid and an appropriate amount of deionized water to the vessel, ultrasonically and stirring for 2 hours;

[0049] d. Keep ultrasonication and stirring, gradually add hydrazine hydrate solution to the container, until the pH value of the solution reaches 8-9, keep ultrasonication and stirring for 0.5 hours;

[0050] e. Keep ultrasonication and stirring, gradually add glucose solution with a concen...

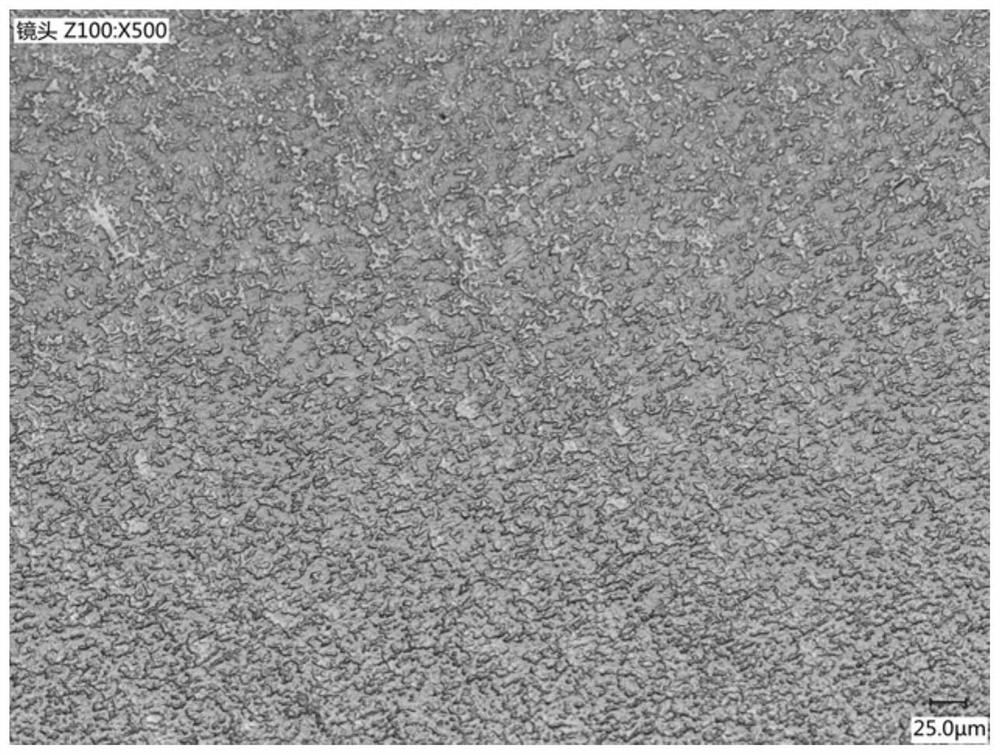

Embodiment 3

[0059] A preparation method of silver-molybdenum contact material, comprising the following steps:

[0060] a. The proportion of molybdenum and additives is 98:1; the additive powder is composed of nickel powder: 0.5-0.8%, copper powder: 0.1-0.3%;

[0061] b. Put molybdenum and additives into the ball mill, the ball milling time is 24H, the rotation speed is 60 rev / min, and the ratio of ball to material is 10:1;

[0062] c, adding 3.5kg of molybdenum additive pretreatment powder and silver nitrate solution into the reaction vessel, then adding 0.015kg polyacrylic acid and an appropriate amount of deionized water to the vessel, ultrasonically and stirring for 2 hours;

[0063] d. Keep ultrasonication and stirring, gradually add hydrazine hydrate solution to the container, until the pH value of the solution reaches 8-9, keep ultrasonication and stirring for 0.5 hours;

[0064] e. Keep ultrasonication and stirring, gradually add glucose solution with a concentration of 100g / L in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com