High-dispersivity silver tungsten carbide electrical contact material and preparation method thereof

A technology of electrical contact materials, silver tungsten carbide, applied in contacts, circuits, electric switches, etc., can solve problems such as limiting the breaking performance of electrical appliances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

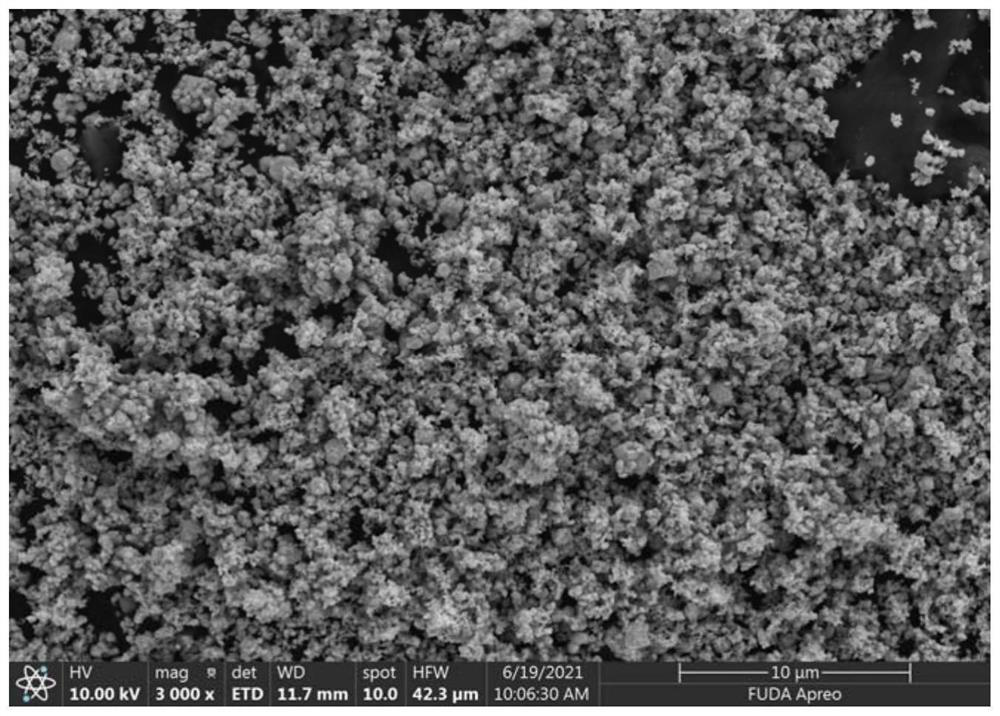

[0030] A preparation method of silver tungsten carbide contact material, comprising the steps of:

[0031] a. The proportion of tungsten carbide and additives is 98:2, and the composition of additives is Fe powder: 0.7-1.0%, Co powder: 0.3-0.5%, nickel powder: 0.3-0.5%;

[0032] b. Put tungsten carbide and additives into the ball mill, the ball milling time is 10H, the speed is 20 rpm, and the ratio of ball to material is 2:1;

[0033] c. Add 3.5kg of tungsten carbide additive pretreatment powder and silver nitrate solution into the reaction container, then add 0.015kg of polyacrylic acid and an appropriate amount of deionized water into the container, ultrasonicate and stir for 2 hours;

[0034] d. Maintain ultrasonication and stirring, gradually add hydrazine hydrate solution to the container until the pH value of the solution reaches 8-9, and maintain ultrasonication and stirring for 0.5 hours;

[0035] e. Keep ultrasonication and stirring, and gradually add glucose soluti...

Embodiment 2

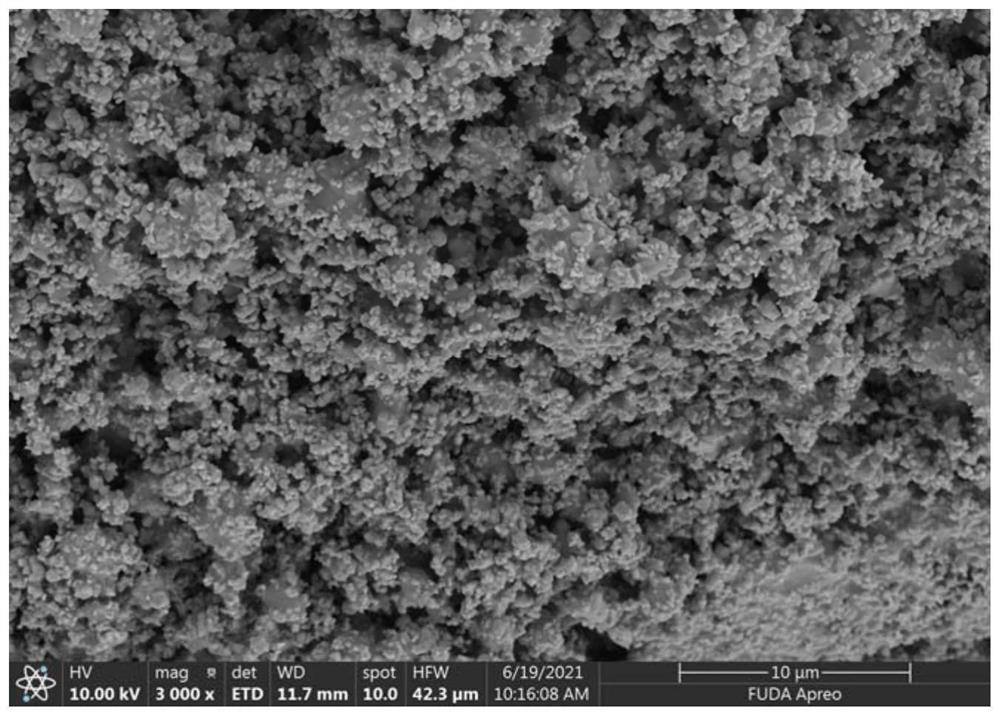

[0043] A preparation method of silver tungsten carbide contact material, comprising the steps of:

[0044] a. The proportion of tungsten carbide and additives is 98:3, and the composition of additives is Fe powder: 1-1.3%, Co powder: 1-1.3%, nickel powder: 0.6-1.0%, copper powder: 0.05-0.2% ;

[0045] b. Put tungsten carbide and additives into the ball mill, the ball milling time is 15H, the speed is 40 rpm, and the ratio of ball to material is 5:1;

[0046]c. Add 3.5kg of tungsten carbide additive pretreatment powder and silver nitrate solution into the reaction container, then add 0.015kg of polyacrylic acid and appropriate amount of deionized water into the container, ultrasonicate and stir for 2 hours;

[0047] d. Maintain ultrasonication and stirring, gradually add hydrazine hydrate solution to the container until the pH value of the solution reaches 8-9, and maintain ultrasonication and stirring for 0.5 hours;

[0048] e. Keep ultrasonication and stirring, and graduall...

Embodiment 3

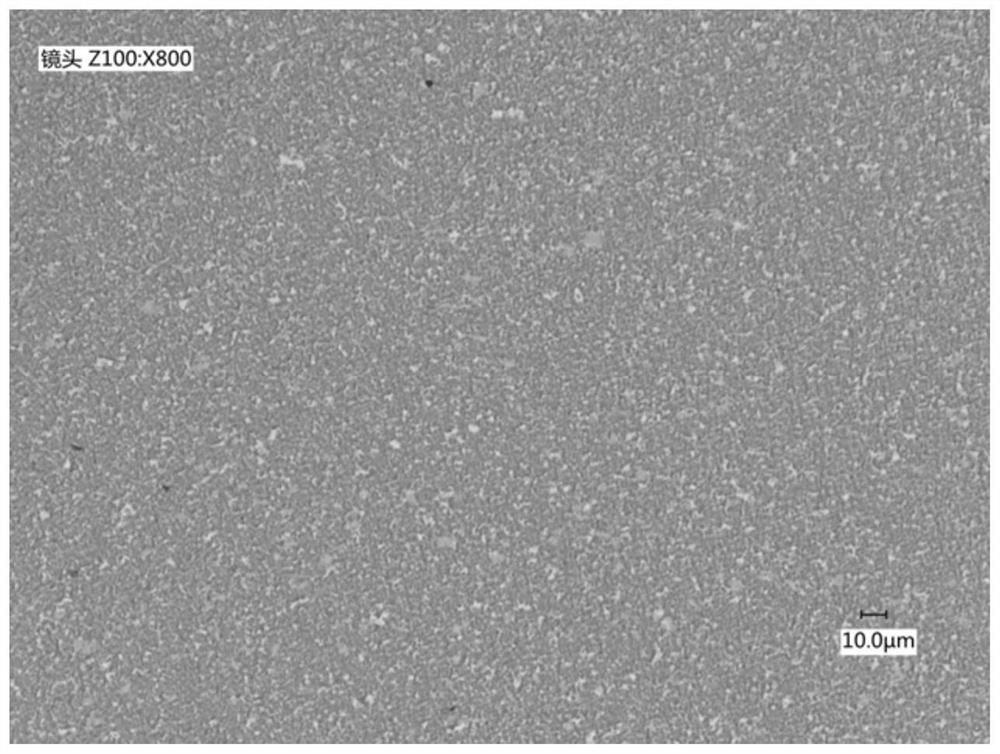

[0057] A preparation method of silver tungsten carbide contact material, comprising the steps of:

[0058] a. The ratio of tungsten carbide and additives is 98:1, and the additives are composed of Co powder: 0.1-0.3%, nickel powder: 0.4-0.7%, copper powder: 0.05-0.2%;

[0059] b. Put tungsten carbide and additives into the ball mill, the ball milling time is 24H, the speed is 60 rpm, and the ball-to-material ratio is 10:1;

[0060] c. Add 3.5kg of tungsten carbide additive pretreatment powder and silver nitrate solution into the reaction container, then add 0.015kg of polyacrylic acid and appropriate amount of deionized water into the container, ultrasonicate and stir for 2 hours;

[0061] d. Maintain ultrasonication and stirring, gradually add hydrazine hydrate solution to the container until the pH value of the solution reaches 8-9, and maintain ultrasonication and stirring for 0.5 hours;

[0062] e. Keep ultrasonication and stirring, and gradually add glucose solution with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com