Forming method of semi-embedded thick copper fine circuit of flexible packaging substrate

A flexible packaging and fine circuit technology, applied in chemical/electrolytic methods to remove conductive materials, printed circuits, printed circuit manufacturing, etc., can solve the difficulty in controlling the shape of copper-plated circuits, the decline in the exposure resolution of photosensitive materials, and affect product quality and other problems, to achieve the effect of easy ink overflow precision control, reduce the occurrence of line peeling, and small ink capillary effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

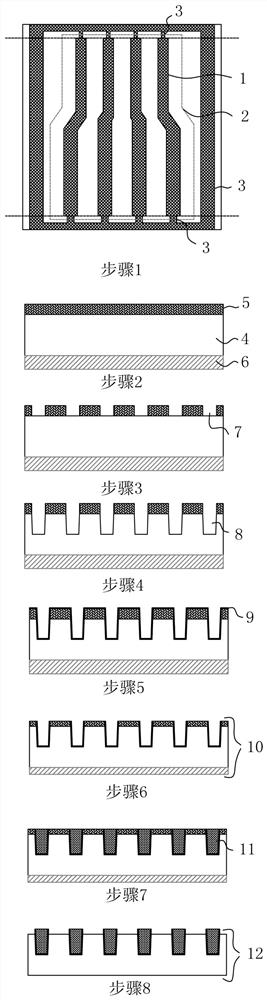

[0034] like figure 1 A method for forming a semi-embedded thick copper fine circuit of a flexible packaging substrate is characterized in that it includes the steps:

[0035] Step 1: In the product design stage, connect the product line 1 to the electroplating wire 3 outside the product outline line 2 to realize electrical conduction during copper electroplating;

[0036] Step 2: Coating a layer of photosensitive material I5 on the upper surface of the polyimide film 4, laminating a layer of photosensitive material II6 on the lower surface of the polyimide film 4;

[0037] Step 3: Exposing the photosensitive material I5 on the upper surface, transferring the circuit pattern to the photosensitive material I5, and developing 7 after the exposure is completed, that is, using the developer to remove the photosensitive material I5 that has decomposed, exposing the polymer. imide film 4;

[0038] Step 4: using an acidic PI etching solution to perform PI etching on the exposed poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com