Preparation method of modified silane defoaming agent for papermaking wastewater

A technology for papermaking wastewater and defoaming agent, applied in the field of silicone defoaming agent, can solve the problems of reducing defoaming efficiency or foam suppressing effect, etc., to improve emulsion stability, improve dispersibility and defoaming performance, and improve defoaming. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

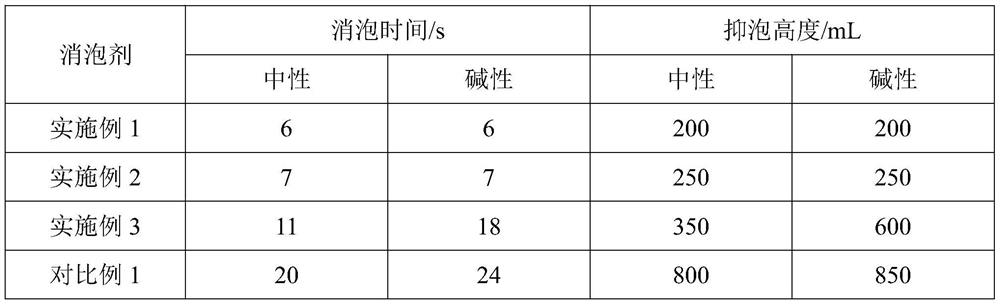

Examples

Embodiment 1

[0031] This embodiment relates to a modified silane paper wastewater foaming agent, and the preparation method thereof includes the following steps:

[0032] S1, respectively weigh the polyether modified organosiloxane and dispersant and mix, stir up to 100-150 ° C, stirring is stirred for 1-2 h, to be cooled to 70 ° C or less, add a composite emulsifier and thickener and mix , Then add water for stirring emulsification, and then cool after deposition to obtain the first emulsion;

[0033] Among them, the polyether modified organosiloxane with the dispersing agent, the composite emulsifier, the thickener, the mass ratio of the water of 40: 9: 11: 1.4: 55;

[0034] S2, respectively, called polysiloxane and dispersing agent, mix, stir up to 160-200 ° C, stir for 1-2 h, to cool to 70 ° C, add composite emulsifier and thickener and mix, add water The mixture is stirred, and the second emulsion is obtained after cooling.

[0035] Among them, the polysiloxane with the dispersing agent, ...

Embodiment 2

[0051] This embodiment relates to a modified silane paper wastewater foamer, and the preparation method is the same as in Example 1, and the difference is that the mixed mass ratio of the first emulsion and the second emulsion is 3: 1.

Embodiment 3

[0053] This embodiment relates to a modified silane paper wastewater foaming agent, and the method of preparing the same example in Example 1 is that the polyether modified organosiloxane is a mass ratio 25: 0 dual-end polyether modification Mixtures of silicone oil and silicone blocking polyclyoxane prepolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com