Process method for preparing high-purity quartz sand by taking cobblestones as raw materials

A technology of high-purity quartz sand and process method, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of complex mineral composition, difficult separation and purification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

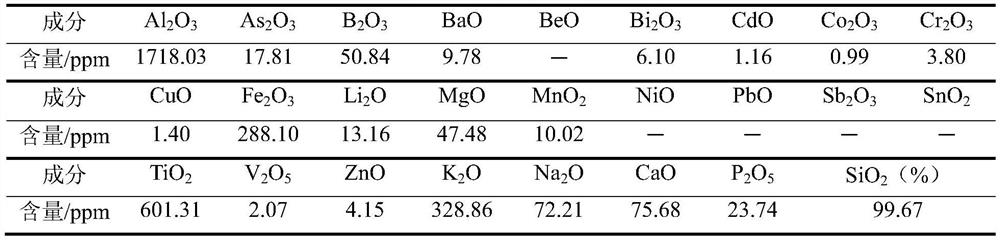

[0024] The No. 1 cobblestone ore from Beihai Hejing Mining Company was used as the raw material, and the ICP test results are shown in Table 1 below.

[0025] The ICP test result of table 1 embodiment 1 raw ore

[0026]

[0027] 1. Sand making: washing and screening the pebbles, manual sorting to remove impurities, crushing, drying, and color sorting to remove the pure white pebbles after removing the variegated stones. Then carry out high-temperature calcination, water quenching, and air drying, and then carry out manual hand selection or color selection to remove particles containing variegated colors, then carry out sand making, magnetic separation, classification, and collect 70-120 mesh quartz sand, and then dehydrate for future use. As raw material quartz sand.

[0028] 2. Pickling and impurity removal: Put the obtained quartz sand into the reaction kettle, and then add 30% hydrochloric acid solution by mass percentage (m / m) for heating and pickling to remove the mec...

Embodiment 2

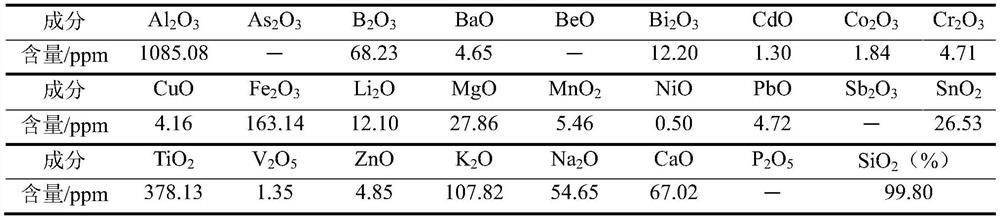

[0034] The No. 2 cobblestone ore from Beihai Hejing Mining Company was used as the raw material, and the ICP test results are shown in Table 2 below.

[0035] The ICP test result of table 2 embodiment 2 raw ore

[0036]

[0037] 1. Sand making: First wash, dry, and color-sort the pebbles to remove impurities, then crush, sand-making, magnetic separation, and classify to collect 40-70 mesh quartz sand, dry, and color-sort for later use.

[0038] 2. Pickling and impurity removal: send the obtained quartz sand into the pickling purification device, and then add (m / m) 31% hydrochloric acid acid solution for heating and pickling to remove the mechanical iron impurities brought in during the sand making process. When the acid solution is 85°C, start to keep warm for 3 hours, stop pickling and remove the acid solution, then raise the temperature in the container to 100°C, so that the hydrogen chloride gas in the acid solution remaining in the container can be quickly volatilized u...

Embodiment 3

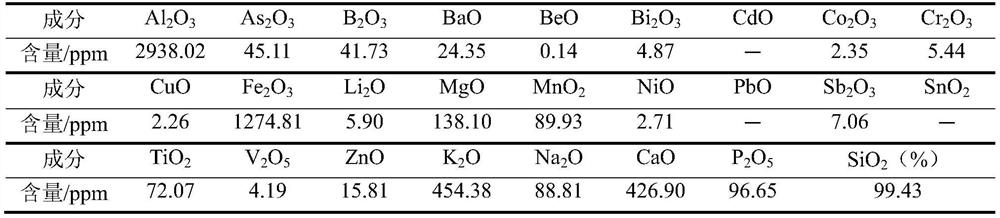

[0044] The No. 3 cobblestone ore from Beihai Hejing Mining Company was used as the raw material, and the ICP test results are shown in Table 3 below.

[0045] The ICP test result of table 3 embodiment 3 ore

[0046]

[0047] 1. Sand making: First wash, dry, and color-sort the pebbles to remove impurities, then crush, sand-making, magnetic separation, and classify and collect 20-40 mesh quartz sand, dry, and color-sort for later use.

[0048] 2. Pickling and impurity removal: Put the quartz sand into the pickling purification container, and then add (m / m) 30% hydrochloric acid acid solution for heating and pickling to remove impurities. After stopping pickling and removing the acid solution, the temperature is raised to 105°C, so that the hydrogen chloride gas in the acid solution remaining in the kettle is quickly volatilized under the suction of the vacuum acid mist absorption device, and then rinsed with acetol to recover the solvent for later use.

[0049] 3. Removal of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com