Marine shellfish amino acid chelated fertilizer and preparation method thereof

A technology of amino acid and shellfish, applied in the direction of nitrate fertilizer, ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, etc., can solve the problem that leftovers cannot be directly fermented and applied to feed, so as to prolong the fertilizer effect and storage time, calcium salt Low content, the effect of preventing pollution damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

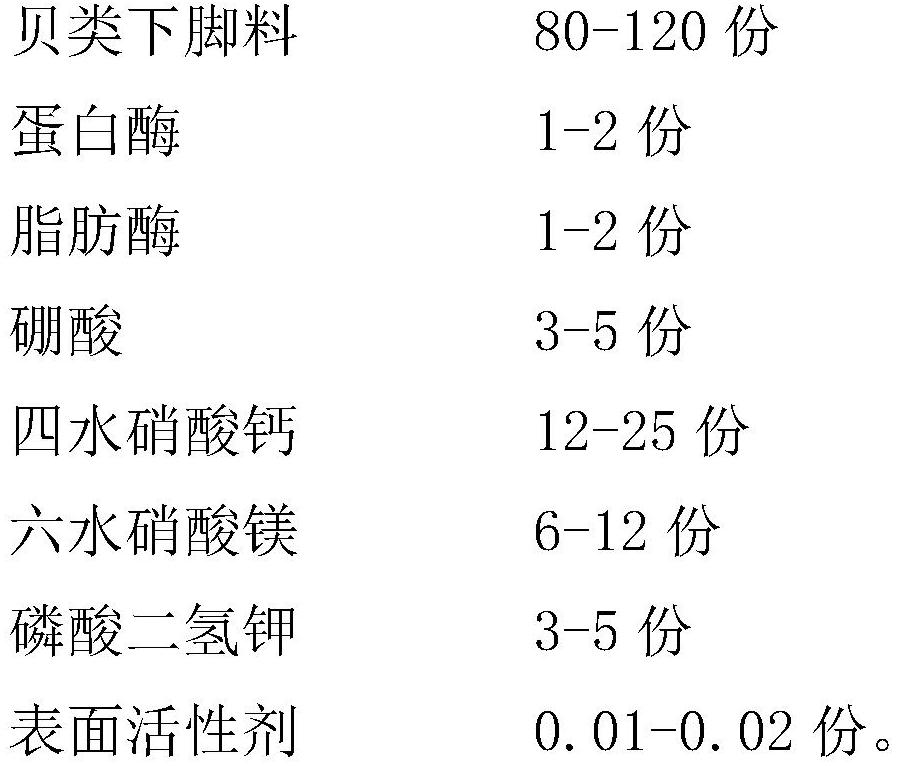

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 A kind of preparation method of marine shellfish amino acid chelate fertilizer, concrete steps are as follows:

[0027] (1) Add 800 parts of clear water to 800 parts of shellfish scraps, and make a slurry.

[0028] (2) Add 10 parts of protease and 10 parts of lipase to the slurry in step (1), stir and enzymolyze at 40°C for 6 hours to obtain the first enzymolysis solution.

[0029] (3) Raise the temperature of the first enzymolysis solution to 80°C for 10 minutes, then lower the temperature to 60°C, and stir for 1 hour to fully react the heavy metal ions with free protein carboxyl groups. Then cool to room temperature, centrifuge at 3000rpm / min for 10min, and the supernatant is the second enzymolysis solution.

[0030] (4) Add 30 parts of boric acid, 120 parts of calcium nitrate tetrahydrate, 60 parts of magnesium nitrate hexahydrate, and 30 parts of potassium dihydrogen phosphate to the second enzymolysis solution for chelation. The temperature is 60 ° C ...

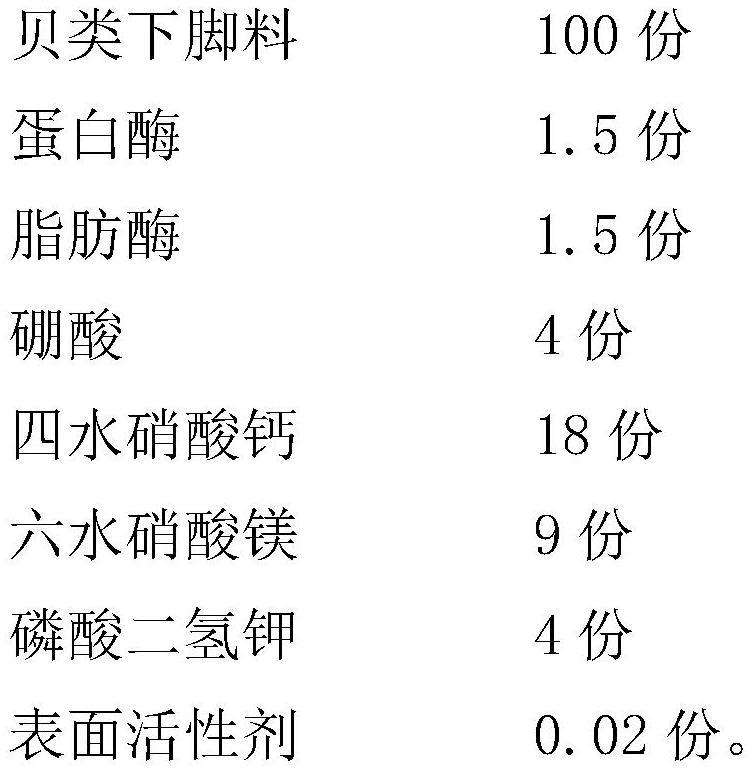

Embodiment 2

[0032] Embodiment 2 A kind of preparation method of marine shellfish amino acid chelate fertilizer, concrete steps are as follows:

[0033] (1) Add 1000 parts of clear water to 1000 parts of shellfish scraps, and make a slurry.

[0034] (2) Add 15 parts of protease and 15 parts of lipase to the slurry in step (1), stir and enzymolyze at 45°C for 7 hours to obtain the first enzymolysis solution.

[0035] (3) Raise the temperature of the first enzymolysis solution to 85°C for 15 minutes, then lower the temperature to 65°C, and stir for 1.5 hours to fully react the heavy metal ions with free protein carboxyl groups. Then cool to room temperature, centrifuge at 4000rpm / min for 15min, and the supernatant is the second enzymolysis solution.

[0036] (4) Add 40 parts of boric acid, 180 parts of calcium nitrate tetrahydrate, 9 parts of magnesium nitrate hexahydrate, and 40 parts of potassium dihydrogen phosphate to the second enzymolysis solution for chelation. The temperature is 65 ...

Embodiment 3

[0038] Embodiment 3 A kind of preparation method of marine shellfish amino acid chelate fertilizer, concrete steps are as follows;

[0039] (1) Add 1200 parts of clear water to 1200 parts of shellfish scraps, and make a slurry.

[0040] (2) Add 20 parts of protease and 20 parts of lipase to the slurry in step (1), stir and enzymolyze at 50°C for 8 hours to obtain the first enzymolysis solution.

[0041] (3) Raise the temperature of the first enzymolysis solution to 90°C for 20 minutes, then lower the temperature to 70°C, and stir for 2 hours to fully react the heavy metal ions with free protein carboxyl groups. Then cool to room temperature, centrifuge at 5000rpm / min for 20min, and the supernatant is the second enzymolysis solution.

[0042] (4) Add 50 parts of boric acid, 250 parts of calcium nitrate tetrahydrate, 120 parts of magnesium nitrate hexahydrate, and 50 parts of potassium dihydrogen phosphate to the second enzymolysis solution for chelation. The temperature is 70°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com