Perovskite quantum dot with core-shell filling layer, preparation method and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

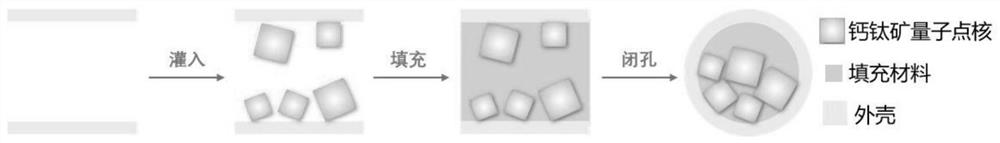

[0054] This embodiment provides a method for preparing perovskite quantum dots with a core-shell filling layer, such as figure 1 Shown, described preparation method comprises:

[0055] (I) Dissolve 0.1g potassium bromide in 25ml deionized water to form a slump agent solution, stir and heat 0.2g MCM-41 molecular sieve powder and slump agent solution at 150°C, the average diameter of MCM-41 molecular sieve powder is 3.5nm, After evaporating to dryness, prepare the material of the shell, the shell material after evaporating to dryness and 0.0667g bulk phase CsPbBr 3 Grinding and mixing, and performing the first heat treatment at 590°C for 30 minutes, so that the perovskite quantum dot core grows in situ in the pores of the shell material, thereby entering the shell;

[0056] (II) Immerse the material prepared in step (I) in 30ml of toluene, add 0.2g of aluminum isopropoxide, ultrasonically disperse and keep stirring for 8 hours, centrifuge and dry, and fill the shell with alumin...

Embodiment 2

[0059] This embodiment provides a method for preparing perovskite quantum dots with a core-shell filling layer, such as figure 1 Shown, described preparation method comprises:

[0060] (I) Dissolve 0.1g potassium bromide in 25ml deionized water to form a slump agent solution, stir and heat 0.2g MCM-41 molecular sieve powder and slump agent solution at 150°C, the average diameter of MCM-41 molecular sieve powder is 3.5nm, After evaporating to dryness, prepare the material of the shell, the shell material after evaporating to dryness and 0.0667g bulk phase CsPbBr 3 Grinding and mixing, and performing the first heat treatment at 590°C for 30 minutes, so that the perovskite quantum dot core grows in situ in the pores of the shell material, thereby entering the shell;

[0061] (II) The material prepared in step (I) was ground with 0.2 g of potassium nitrate, and heat-treated at 350° C. for 60 min to prepare the perovskite quantum dots with a core-shell filling layer.

Embodiment 3

[0063] This embodiment provides a method for preparing perovskite quantum dots with a core-shell filling layer, such as figure 1 Shown, described preparation method comprises:

[0064] (I) Dissolve 0.1g of potassium bromide in 25ml of deionized water to form a slump agent solution, stir and heat 0.2g of SBA molecular sieve powder and slump agent solution at 150°C, the average pore size of the SBA molecular sieve powder is 6nm, evaporate to dryness and prepare Obtain the material of the shell, the shell material and 0.0667g bulk phase CsPbBr after evaporation to dryness 3 Grinding and mixing, and performing the first heat treatment at 590°C for 30 minutes, so that the perovskite quantum dot core grows in situ in the pores of the shell material, thereby entering the shell;

[0065] (II) Immerse the material prepared in step (I) in 30ml of toluene, add 0.2g of aluminum isopropoxide, ultrasonically disperse and keep stirring for 8 hours, centrifuge and dry, and fill the shell wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com