Graphite negative electrode material and preparation method and application thereof

A graphite anode, natural graphite technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of reducing the energy density of graphite composite materials, requiring high temperature and high pressure equipment, and deteriorating battery cycle performance. Chemical stability, simple and feasible method, effect of improving gram capacity and energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

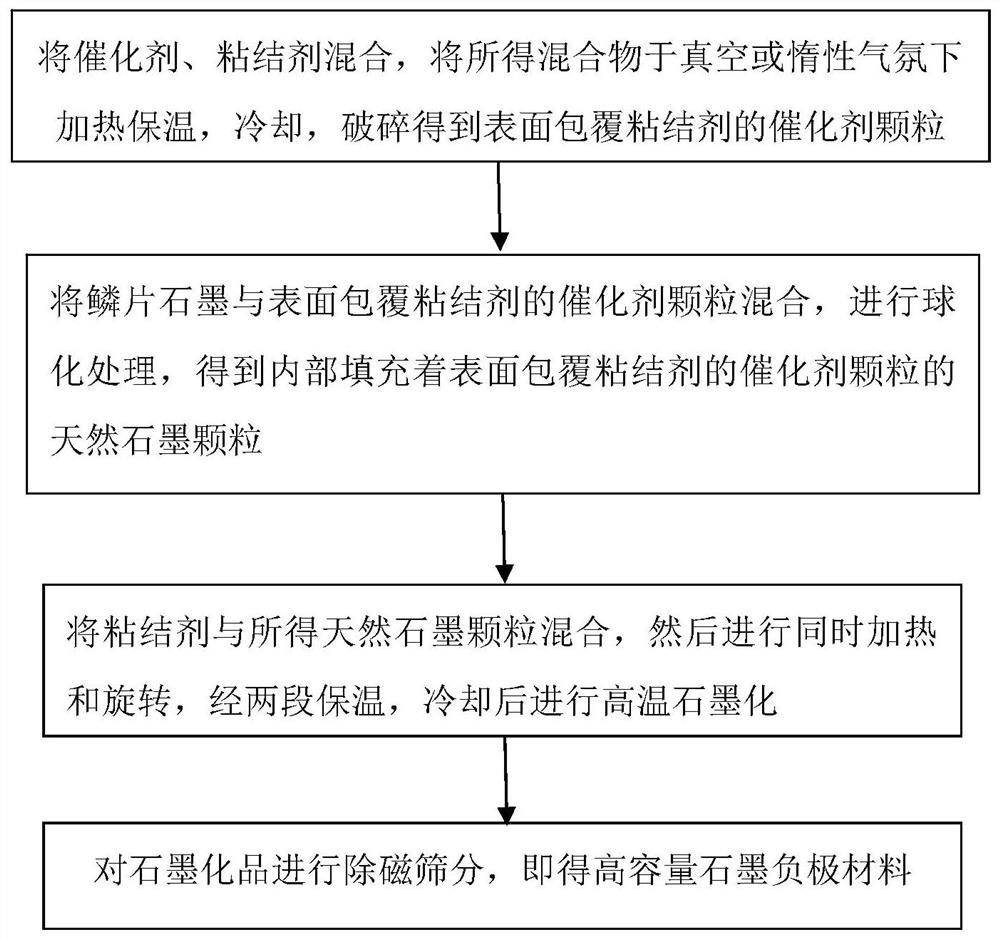

[0032] In order to solve the technical problems such as the poor cycle performance of existing graphite negative electrode materials and the capacity to be improved, the invention provides a preparation method of graphite negative electrode materials, comprising the following steps:

[0033] S1. Mix the catalyst with the binder 1, place the obtained mixture under an inert atmosphere or vacuum condition, raise the temperature to 100-300°C, keep it warm for 2-4 hours, cool to room temperature, and crush to obtain the coated binder 1 Particle A of the catalyst, the particle A is close to the particle size of the catalyst;

[0034] S2. Mix the catalyst particle A coated with the binder 1 and flake graphite to obtain a mixture X, and the mixture X is spheroidized to obtain spherical natural graphite particles B, which are filled with coated Catalyst particle A of binder 1;

[0035] S3. Mix the spherical natural graphite particles B obtained in step S2 with the binder 2 to obtain a...

Embodiment 1

[0049] A preparation method of the graphite negative electrode material of the present embodiment, its preparation process is as follows figure 1 shown, including the following steps:

[0050] (1) the average particle diameter is 3 μ m of SiC and the average particle diameter is 3 μ m of petroleum asphalt mixing, the mass percentage of petroleum pitch is 30%, the mass percentage of SiC is 70%, the mixture is packed in the container, will house The container of the mixture was placed in a carbonization furnace, and the temperature was raised to 250°C at a rate of 3°C / min under a nitrogen atmosphere, kept for 2 hours, and then the temperature was naturally lowered to crush the material. The particle size after crushing was 3.2 μm.

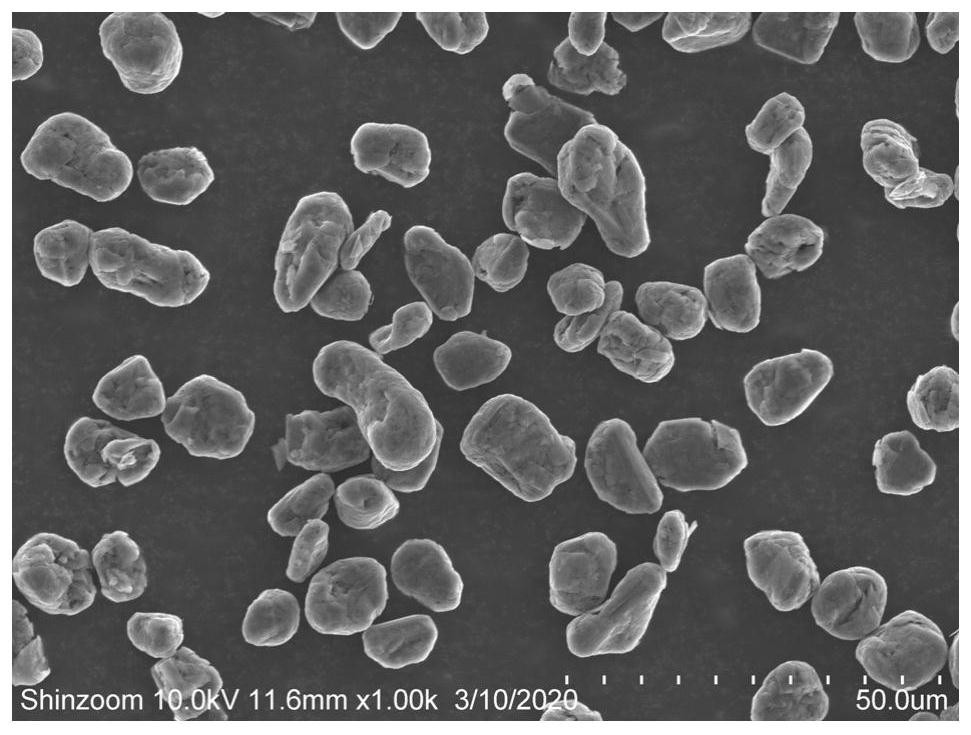

[0051] (2) SiC coated with petroleum pitch and flake graphite with an average particle size of 35 μm are mixed evenly. The SiC coated with graphite pitch is 20% of the total mass of SiC and graphite flakes coated with petroleum pitch. The mixture is ...

Embodiment 2

[0071] A preparation method of a graphite negative electrode material is basically the same as in Example 1, the only difference being that in the step (1) of Example 2, the mass percent of petroleum pitch is 15%, and the mass percent of SiC is 85%.

[0072] The graphite negative electrode material prepared by this method was made into a button battery and a full battery according to the method in Example 1, and the electrochemical performance results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com