Preparation method of nickel cobalt lithium manganate ternary positive electrode material

A technology of nickel-cobalt lithium manganese oxide and positive electrode materials, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of poor cycle performance, low compaction density, and low mechanical strength of materials, and achieve high compaction density and hardness , Improve the compressive capacity, improve the effect of Ni-O bond energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

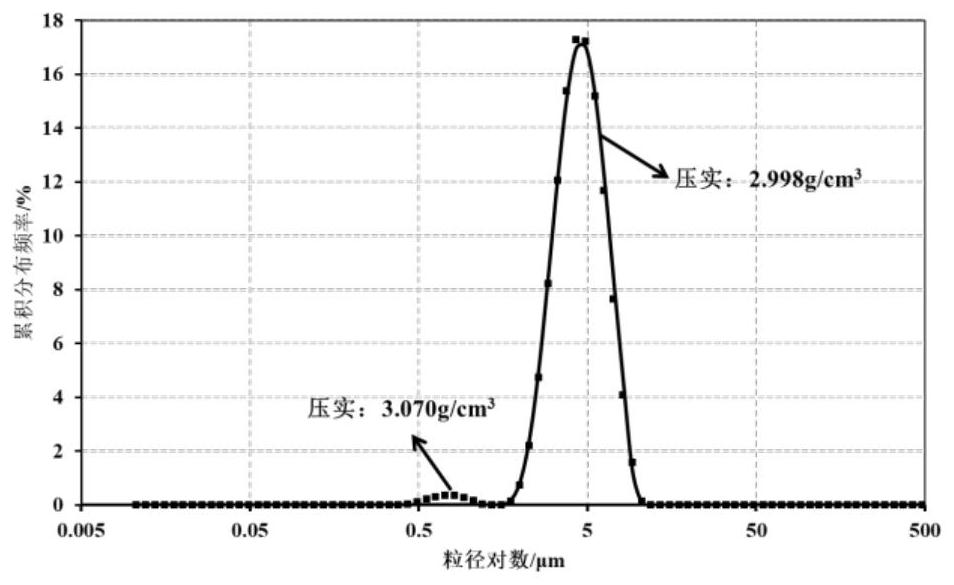

[0049] Weigh NiSO according to the ratio of Ni:Co:Mn:Al molar ratio of 0.8782:0.09:0.03:0.0018 4 ·6H2 O. CoSO 4 ·7H 2 O, MnSO 4 ·H 2 O and Al 2 (SO 4 ) 3 , fully dissolved in deionized water to prepare an aqueous solution, control the flow rate, and mix the aqueous solution with NaOH and NH 4 OH was continuously added into the 2.5L reactor, the reaction pH was controlled to be 11-12, the reaction temperature was 50°C, and the stirring rate was 800-1000rpm, and the precursor containing Al (Ni 0.8782 co 0.09 mn 0.03 al 0.0018 )(OH) 2 , the precursor is filtered and dried for use. Lithium hydroxide monohydrate and the above precursors were weighed at a molar ratio of 1.020:1. Mix 30% lithium hydroxide monohydrate and all the precursors evenly, bake at 500° C. for 3 hours in an atmosphere with an oxygen volume concentration of 95%, and cool down naturally to obtain a calcined product. After the calcined product is crushed and sieved, the remaining 70% lithium hydroxid...

Embodiment 2

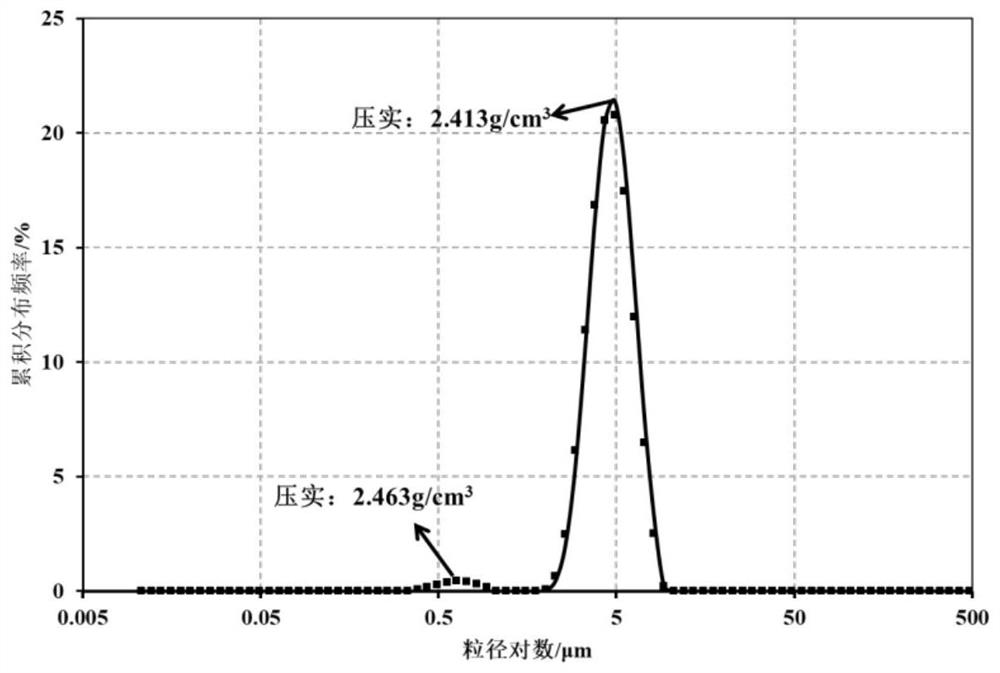

[0051] Weigh NiSO according to the ratio of Ni:Co:Mn:Al molar ratio of 0.87892:0.09:0.03:0.00108 4 ·6H 2 O. CoSO 4 ·7H 2 O, MnSO 4 ·H 2 O and Al 2 (SO 4 ) 3 , fully dissolved in deionized water to prepare an aqueous solution, control the flow rate, continuously add the aqueous solution, NaOH and NH4OH to a 2.5L reaction kettle, control the reaction pH=11-12, the reaction temperature is 50°C, and the stirring rate is 800-1000rpm. Precursors of Al elements (Ni 0.87892 co 0.09 mn 0.03 al 0.00108 )(OH) 2 , the precursor was filtered and dried before use, and the lithium hydroxide monohydrate and the precursor were weighed at a molar ratio of 1.020:1. Mix 30% lithium hydroxide monohydrate and all the precursors evenly, bake at 500° C. for 3 hours in an atmosphere with an oxygen volume concentration of 95%, and cool down naturally to obtain a calcined product. After the calcined product is crushed and sieved, the remaining 70% lithium hydroxide monohydrate and a certain...

Embodiment 3

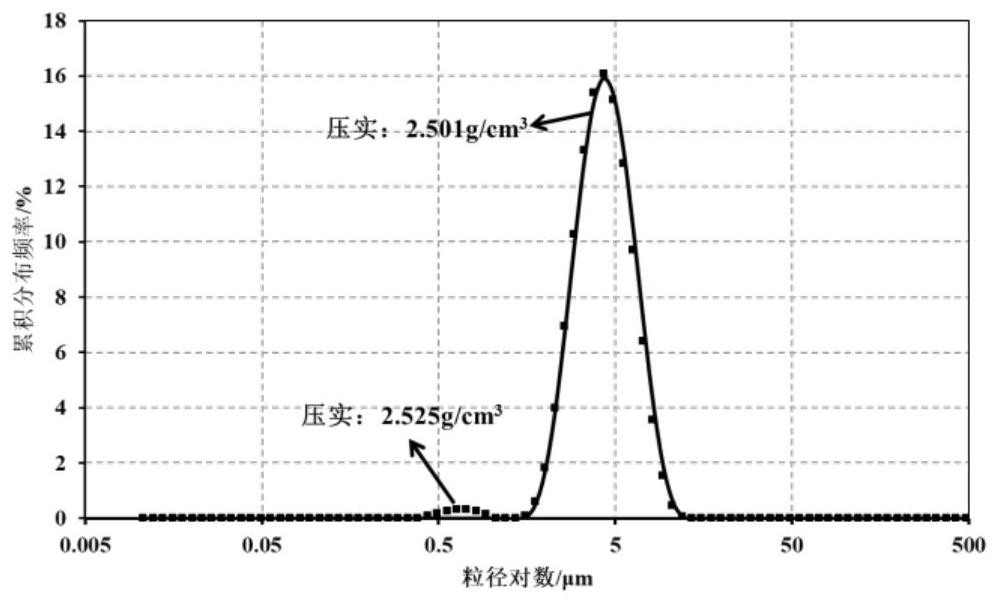

[0053] Weigh NiSO according to the ratio of Ni:Co:Mn:Al molar ratio of 0.8764:0.09:0.03:0.0036 4 ·6H 2 O. CoSO 4 ·7H 2 O, MnSO 4 ·H 2 O and Al 2 (SO 4 ) 3 , fully dissolved in deionized water to prepare an aqueous solution, control the flow rate, and mix the aqueous solution with NaOH and NH 4 OH was continuously added into the 2.5L reactor, the reaction pH was controlled to be 11-12, the reaction temperature was 50°C, and the stirring rate was 800-1000rpm, and the precursor containing Al (Ni 0.8764 co 0.09 mn 0.03 al 0.0036 )(OH) 2 , the precursor is filtered and dried for use. Lithium hydroxide monohydrate and precursor were weighed at a molar ratio of 1.020:1. Mix 30% lithium hydroxide monohydrate and all the precursors uniformly, bake at 500° C. for 3 hours in an atmosphere with an oxygen volume concentration of 95%, and cool down by autothermal cooling to obtain a calcined product. After the calcined product is crushed and sieved, the remaining 70% lithium h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com