Holmium molybdate pigment as well as preparation method and application thereof

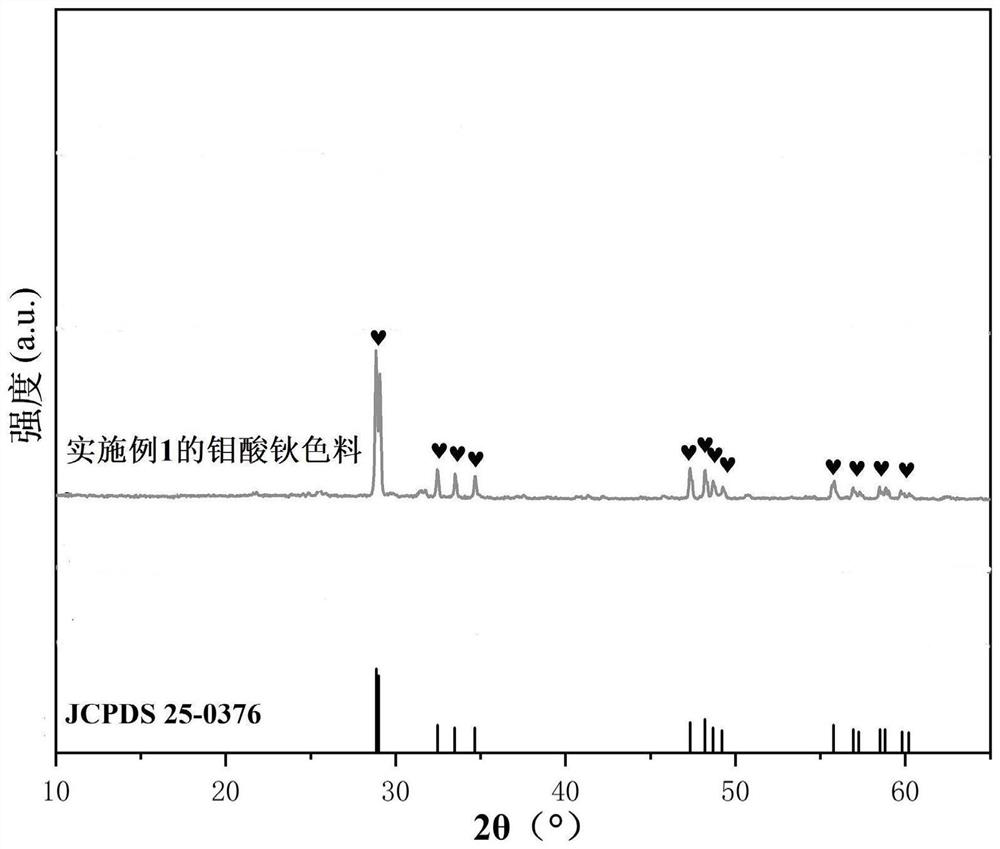

A technology of coloring material and molybdic acid, which is applied in the field of holmium molybdate coloring material and its preparation, can solve the problems that limit the large-scale popularization and application of holmium molybdate coloring material, high calcination temperature, long reaction time, etc., and achieve low production cost, disperse Good stability and single crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

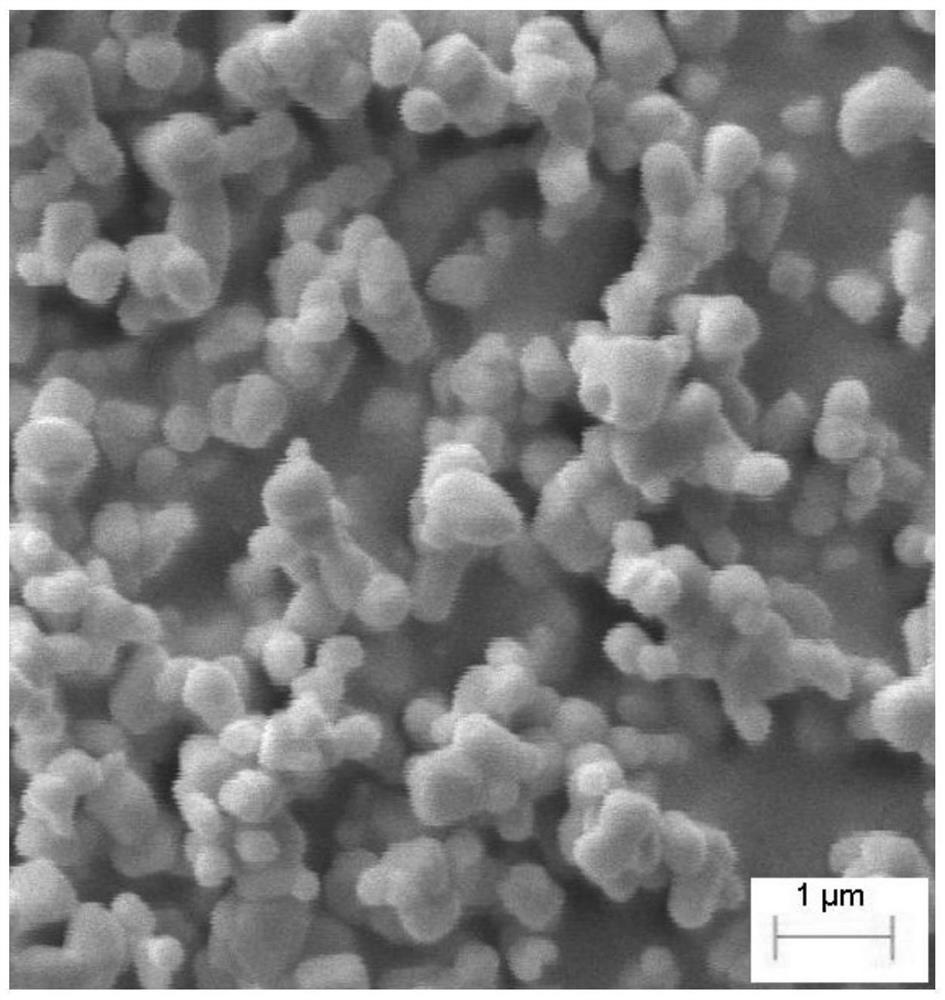

Embodiment 1

[0037] A kind of holmium molybdate pigment, its preparation method comprises the following steps:

[0038] 1) Add 0.0196mol of holmium nitrate to 100mL of nitric acid with a concentration of 4mol / L, stir evenly to obtain a holmium-containing solution, and add 0.0014mol of ammonium heptamolybdate to 100mL of deionized water, stir evenly to obtain a molybdenum-containing solution ;

[0039] 2) slowly and uniformly adding the holmium-containing solution to the molybdenum-containing solution to obtain a blended solution;

[0040] 3) Add ammonia water dropwise into the blended solution until the pH of the blended solution is 7.5, then let it stand for aging for 3 hours, centrifuge, wash the solid precipitates obtained by centrifugation with deionized water and absolute ethanol respectively 3 times each, to obtain Precipitate;

[0041] 4) Put the precipitate in a blast drying oven, dry it at 80°C for 18 hours, then place it in a muffle furnace, and keep it warm at 1000°C for 3 hou...

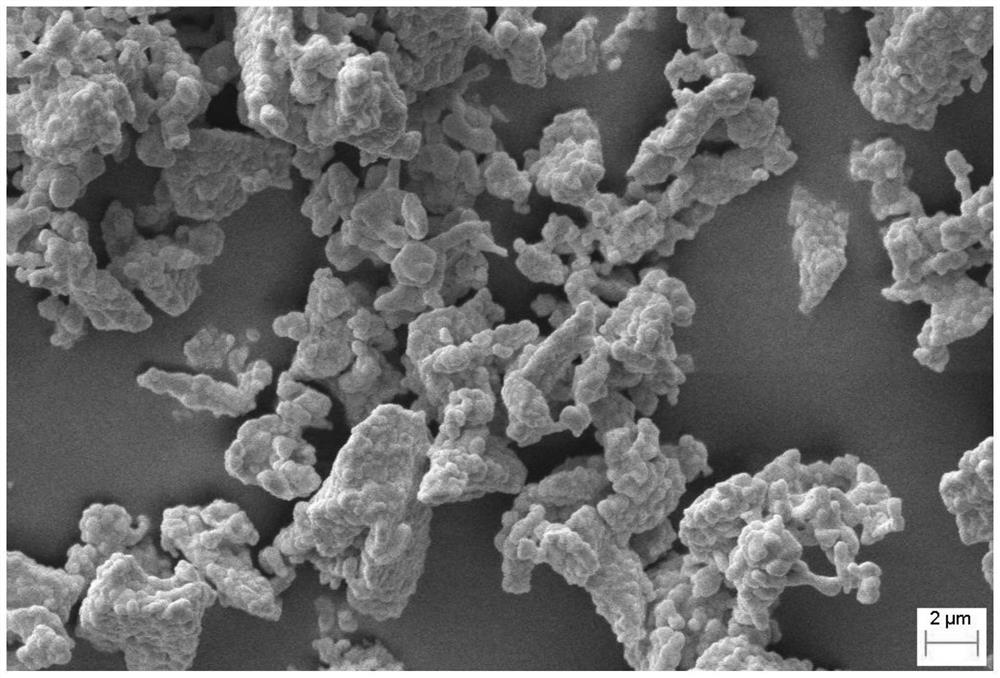

Embodiment 2

[0048] A kind of holmium molybdate pigment, its preparation method comprises the following steps:

[0049] 1) Add 0.0196mol of holmium nitrate to 150mL of nitric acid with a concentration of 3mol / L, stir evenly to obtain a holmium-containing solution, and add 0.0026mol of ammonium tetramolybdate to 200mL of deionized water, stir evenly to obtain a molybdenum-containing solution ;

[0050] 2) slowly and uniformly adding the holmium-containing solution to the molybdenum-containing solution to obtain a blended solution;

[0051] 3) Add ammonia water dropwise to the blended solution until the pH of the blended solution is 7.0, then let it stand and age for 2 hours, centrifuge, wash and centrifuge the solid precipitate obtained by deionized water and absolute ethanol three times respectively, to obtain Precipitate;

[0052] 4) Put the precipitate in a blast drying oven, dry it at 60°C for 24 hours, then place it in a muffle furnace, and keep it at 1100°C for 2 hours to obtain the...

Embodiment 3

[0057] A kind of holmium molybdate pigment, its preparation method comprises the following steps:

[0058] 1) Add 0.02mol of holmium chloride to 200mL of hydrochloric acid with a concentration of 2mol / L, stir well to obtain a solution containing holmium, and add 0.0016mol of ammonium heptamolybdate to 75mL of deionized water, stir well to obtain a solution containing molybdenum solution;

[0059] 2) slowly and uniformly adding the holmium-containing solution to the molybdenum-containing solution to obtain a blended solution;

[0060] 3) Add ammonia water dropwise to the blended solution until the pH of the blended solution is 8.0, then let it stand for aging for 4 hours, centrifuge, and wash the solid precipitates obtained by centrifugation with deionized water and absolute ethanol for 3 times respectively, to obtain Precipitate;

[0061] 4) Put the precipitate in a blast drying oven, dry it at 70°C for 20 hours, then place it in a muffle furnace, and keep it warm at 1200°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com