A kind of preparation and use method of manganese dioxide catalyst for catalytic oxidation of toluene

A manganese dioxide, catalytic oxidation technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem that oxygen vacancies cannot be completely stable and difficult to disproportionate Control and other issues to achieve the effect of preventing agglomeration, simple steps, and strong high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

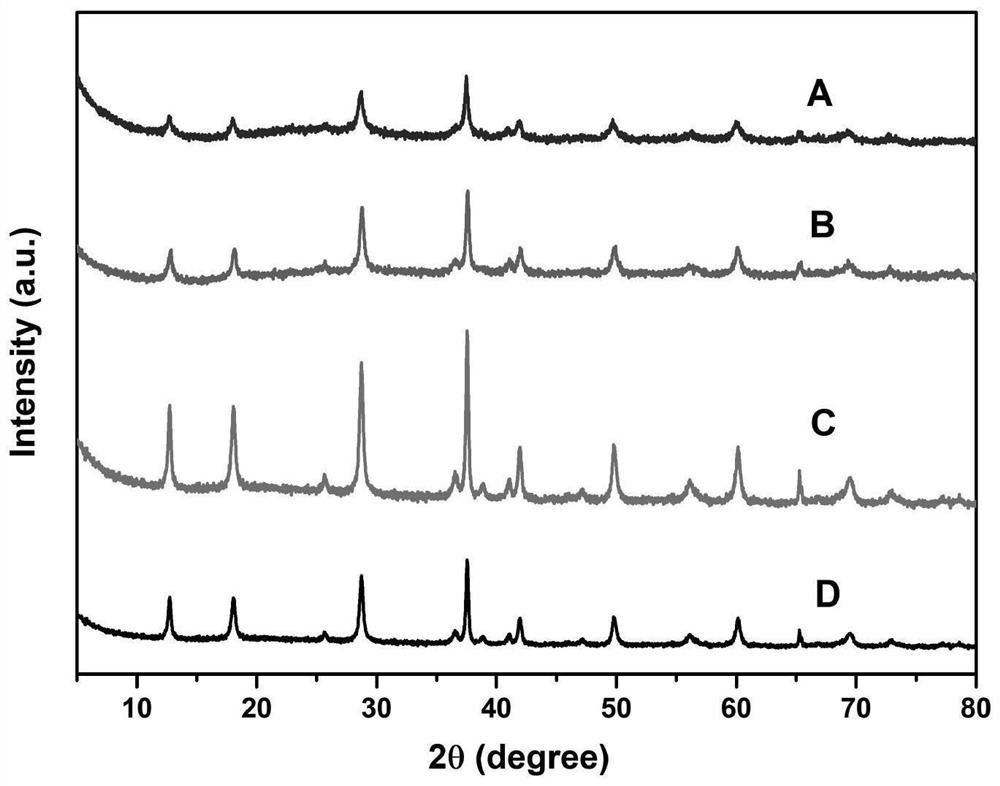

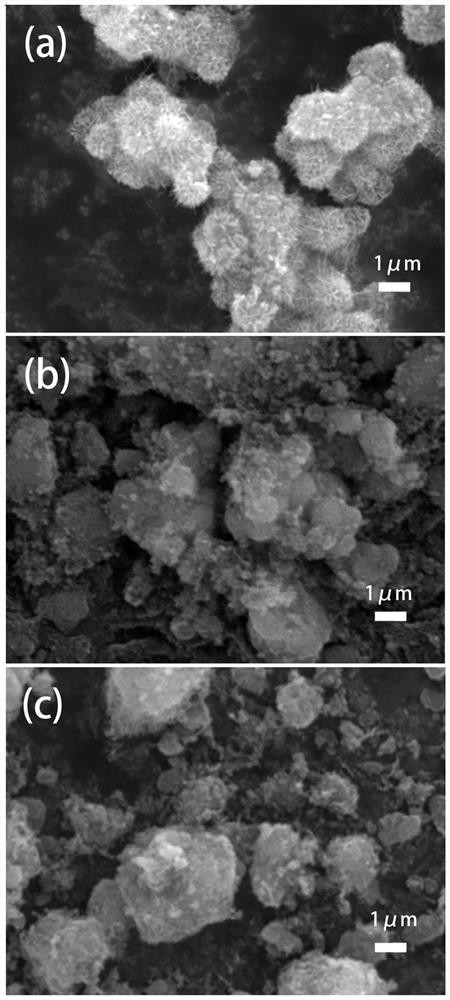

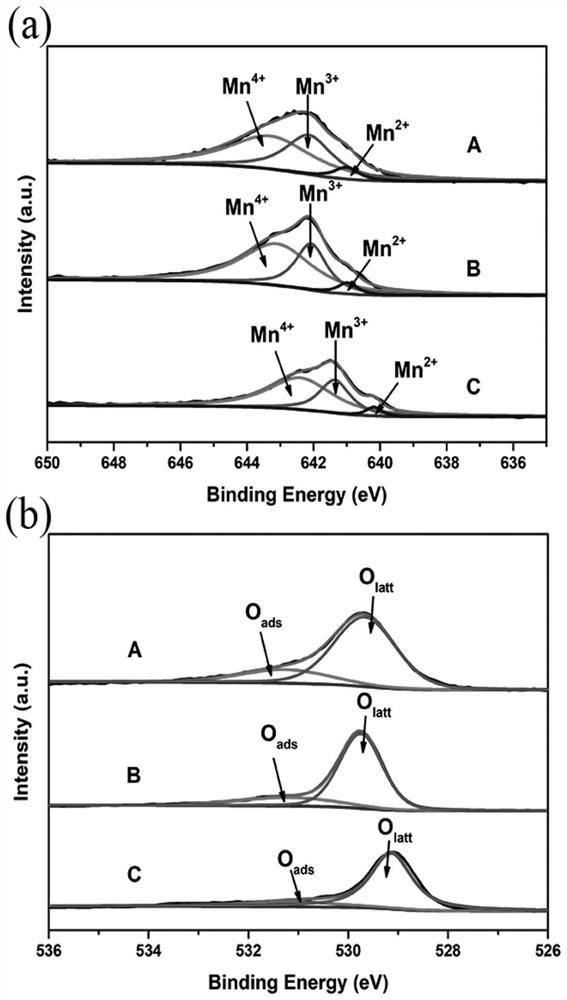

Embodiment 1

[0041] (1) Mix 20mL concentration 0.20mol / L potassium hydroxide aqueous solution and 20mL concentration 0.10mol / L potassium permanganate aqueous solution at normal temperature, then add dropwise to 20mL concentration 1.00mol / L n-butanol aqueous solution, be warming up to Continue stirring at 60°C for 30min, after the reaction is completed, the product is suction filtered and washed with deionized water, and the obtained filter cake is vacuum-dried at 60°C to obtain a low-crystallinity spherical manganese dioxide precursor with an average particle size of less than 100 nm;

[0042] (2) adding 2 mmol of the precursor to 20 mL of manganese sulfate solution with a concentration of 0.10 mol / L to form a dispersion, then adding 20 mL of ethylenediaminetetraacetic acid (EDTA) disodium salt aqueous solution with a concentration of 0.05 mol / L under stirring, Then ultrasonically treated for 30min, then continue to add 60mL of 0.10mol / L potassium permanganate aqueous solution dropwise to t...

Embodiment 2

[0045] (1) 20mL concentration of 0.10mol / L urea aqueous solution and 20mL concentration of 0.10mol / L potassium permanganate aqueous solution were mixed at normal temperature, then added dropwise to 20mL concentration of 1.00mol / L ethanol aqueous solution, heated to 60 ℃ and continued to stir 30min, after the reaction is completed, the product is suction filtered and washed with deionized water, and the obtained filter cake is vacuum-dried at 60 ° C to obtain a low-crystallinity spherical manganese dioxide precursor with an average particle size of less than 100 nm;

[0046] (2) adding 2 mmol of the precursor to 20 mL of manganese sulfate solution with a concentration of 0.10 mol / L to form a dispersion, then adding 20 mL of ethylenediaminetetraacetic acid (EDTA) disodium salt aqueous solution with a concentration of 0.05 mol / L under stirring, Then ultrasonically treated for 30min, then continue to add 60mL of 0.10mol / L potassium permanganate aqueous solution dropwise to the abov...

Embodiment 3

[0049] (1) 20mL concentration 0.20mol / L sodium hydroxide aqueous solution and 20mL concentration 0.10mol / L potassium permanganate aqueous solution are mixed evenly at room temperature, and then dropwise added to 20mL concentration 1.00mol / L n-butanol aqueous solution, and the temperature is increased to Continue stirring at 60°C for 30min, after the reaction is completed, the product is suction filtered and washed with deionized water, and the obtained filter cake is vacuum-dried at 60°C to obtain a low-crystallinity spherical manganese dioxide precursor with an average particle size of less than 100 nm;

[0050] (2) 2 mmol of the precursor is added to 20 mL of manganese sulfate solution with a concentration of 0.10 mol / L to form a dispersion, and then 20 mL of EDTA disodium salt aqueous solution with a concentration of 0.05 mol / L is added under stirring, Then ultrasonically treated for 30min, then continue to add 60mL of 0.10mol / L sodium permanganate aqueous solution dropwise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com