Expanded head anchor cable/rod construction device and method

A construction device and expanding head technology, which is applied in excavation, foundation structure engineering, construction, etc., can solve the problems of inability to accurately control the diameter of the reaming hole, affect the pull-out bearing capacity of the anchor cable, and the hole wall is easy to collapse, etc., to improve the construction process, The effect of shortening the construction period, simple overall structure and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

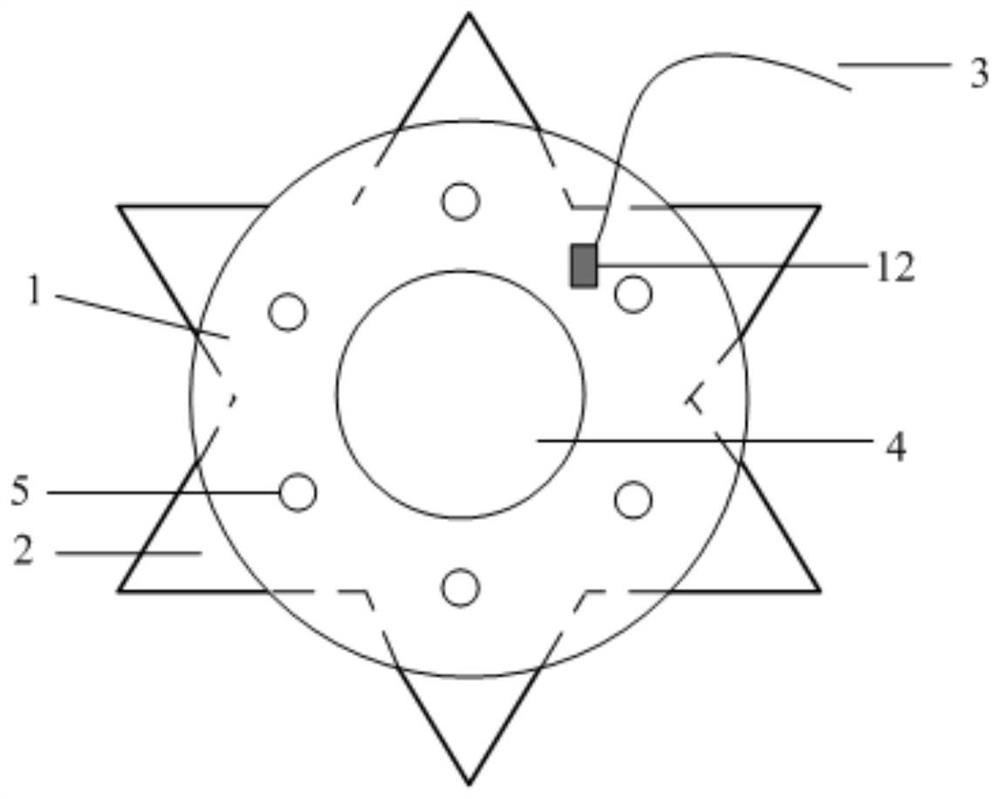

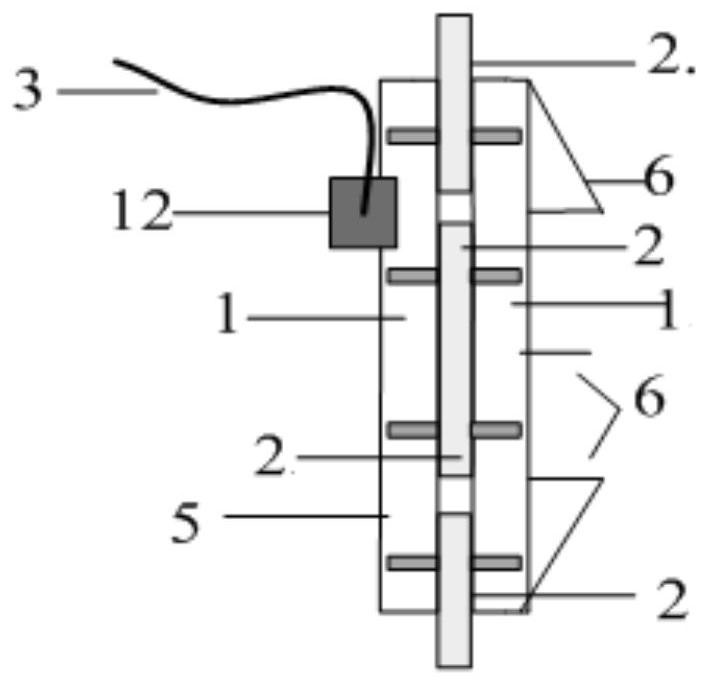

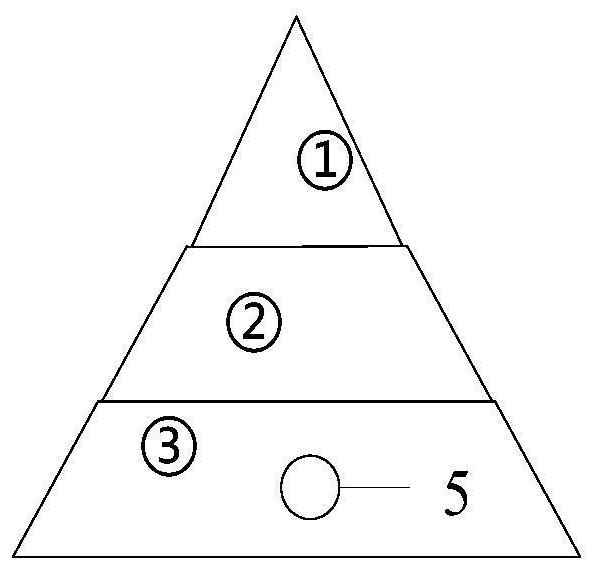

[0029] The main structure of the expansion head anchor cable / rod construction device described in this embodiment includes: hollow gaskets 1 on both sides, gears 2, control lines 3, round holes 4, connecting strips 5, cutting knives 6, drill pipes 7, and drill bits 9 , buckle 10, controller 11, electric device 12 and steel strand 13; the hollow gasket 1 on both sides is threadedly connected with the gear 2 through the connecting bar 5, and a round hole 4 is arranged in the middle of the hollow gasket 1 on both sides, and the control line 3 is wound on the drill pipe 7 and rotates with the drill pipe 7, the control line 3 is connected to the controller 11, and the controller 11 transmits the electric signal to the electric device 12 through the control line 3, and the electric device 12 is composed of a micro motor, a control mechanism and an electric Partial composition, the electric device 12 receives the electric signal and converts it into power through the control mechanism...

Embodiment 2

[0037] This embodiment adopts the device described in Embodiment 1 to carry out anchor cable construction in the water-rich sand layer area (aperture 180mm, reaming diameter 450mm, hole depth about 20m), specifically including the following steps:

[0038] (1) Drilling positioning: according to the local geological conditions, the excavated foundation pit is determined according to the elevation and horizontal spacing required by the design, and the hole position is determined and marked;

[0039] (2) Drilling machine positioning: select the drilling machine according to the actual needs, connect the hollow gasket 1 on both sides with the gear 2 installed on the drill pipe 7 through the buckle 10, and install the drill bit 9 on the end of the drill pipe 7 to align the hole position, adjust the angle, and ensure that the installation is qualified before drilling;

[0040] (3) Drilling: use the gear 2 to mechanically rotate the hole, wind the control line 3 covered with "Kevlar"...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com