Electrode material for reducing volume change of electrode in charging and discharging process and battery

An electrode material and battery technology, applied in the direction of non-aqueous electrolyte batteries, battery electrodes, lithium batteries, etc., can solve the problems of energy density reduction and battery energy density reduction, improve electrical performance, prevent electrode materials from falling off, and simple operation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: the preparation of electrode material, battery

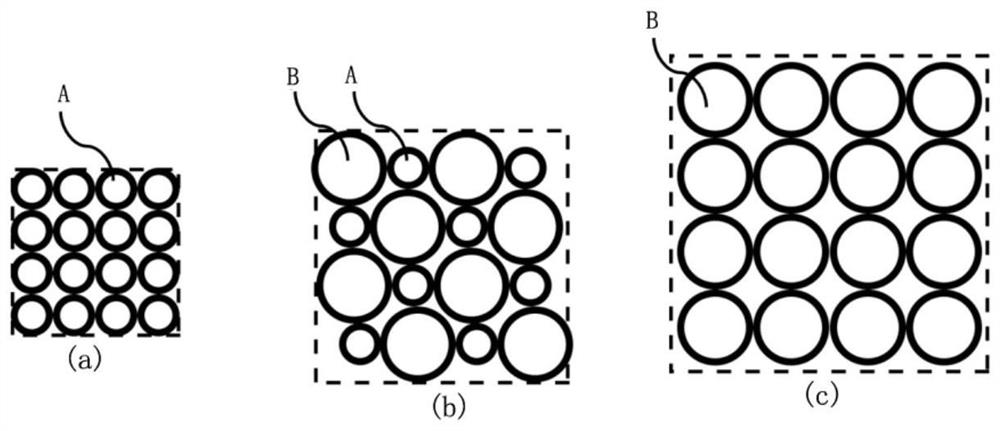

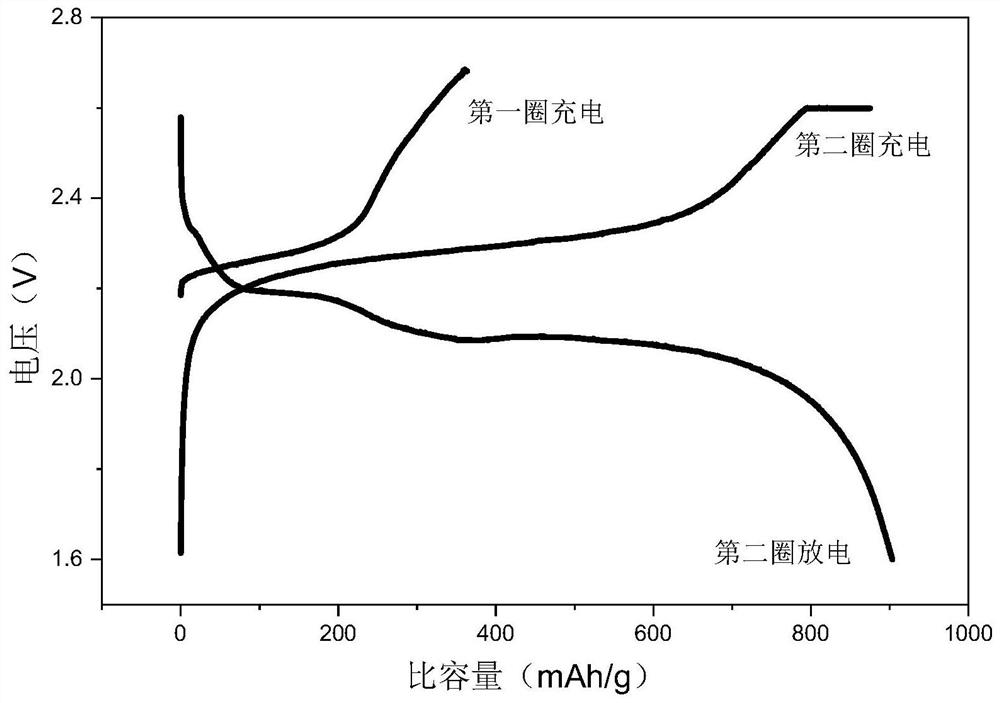

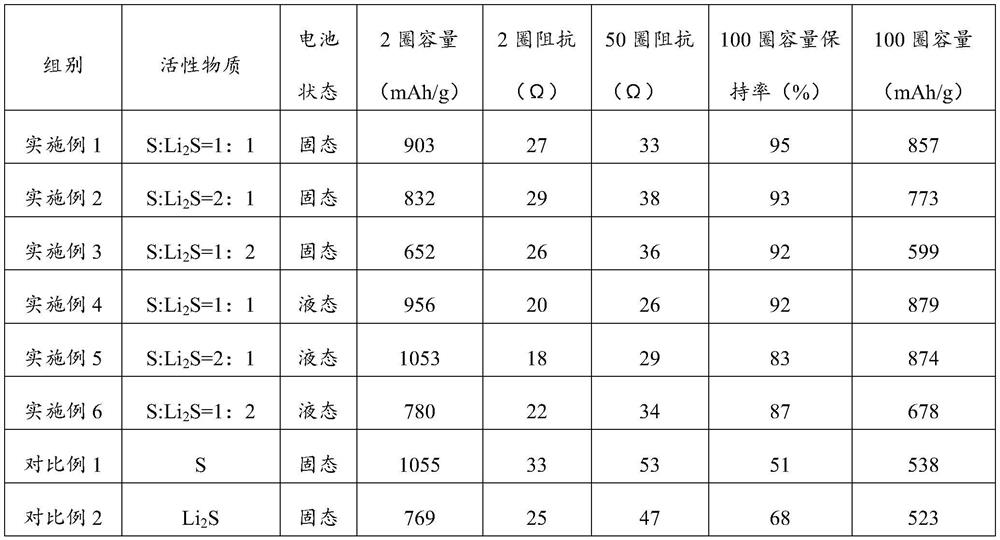

[0047] A kind of electrode material that reduces the volume change of battery electrode in charge and discharge process, comprises active material, and active material comprises charge product and discharge product; charge product and discharge product are sulfur (S) and lithium sulfide (Li 2 S), sulfur (S) and lithium sulfide (Li 2 The molar ratio of S) is 1:1;

[0048] Electrode materials also include electrolytes (sulfide electrolyte Li 6 P.S. 5 Cl) and conducting agent (acetylene black), the quality of electrolyte is 10% of the mass of active material; The quality of conducting agent is 10% of the mass of active material.

[0049] The preparation method of the above-mentioned electrode material for reducing the volume change of the battery electrode during charging and discharging comprises the following steps:

[0050] (1) The dried S and Li 2 S, mix according to the molar ratio of 1:1, add 100 zir...

Embodiment 2

[0055] Embodiment 2: the preparation of electrode material, battery

[0056] Compared with Example 1, the molar ratio of sulfur and lithium sulfide in Example 2 was adjusted to 2:1, and the rest of the components and preparation process were the same as in Example 1.

Embodiment 3

[0057] Embodiment 3: the preparation of electrode material, battery

[0058] Compared with Example 1, the molar ratio of sulfur and lithium sulfide in Example 3 was adjusted to 1:2, and the rest of the components and preparation process were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com