Fireproof and explosion-proof box special for battery

An explosion-proof box and battery technology, which is applied in the direction of secondary batteries, battery pack components, and battery isolation from its environment, can solve problems such as poor applicability, failure to consider the impact of charging performance and charging safety, inconvenient movement and isolation, etc. , to achieve the effect of good sealing, no chain reaction, light size and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

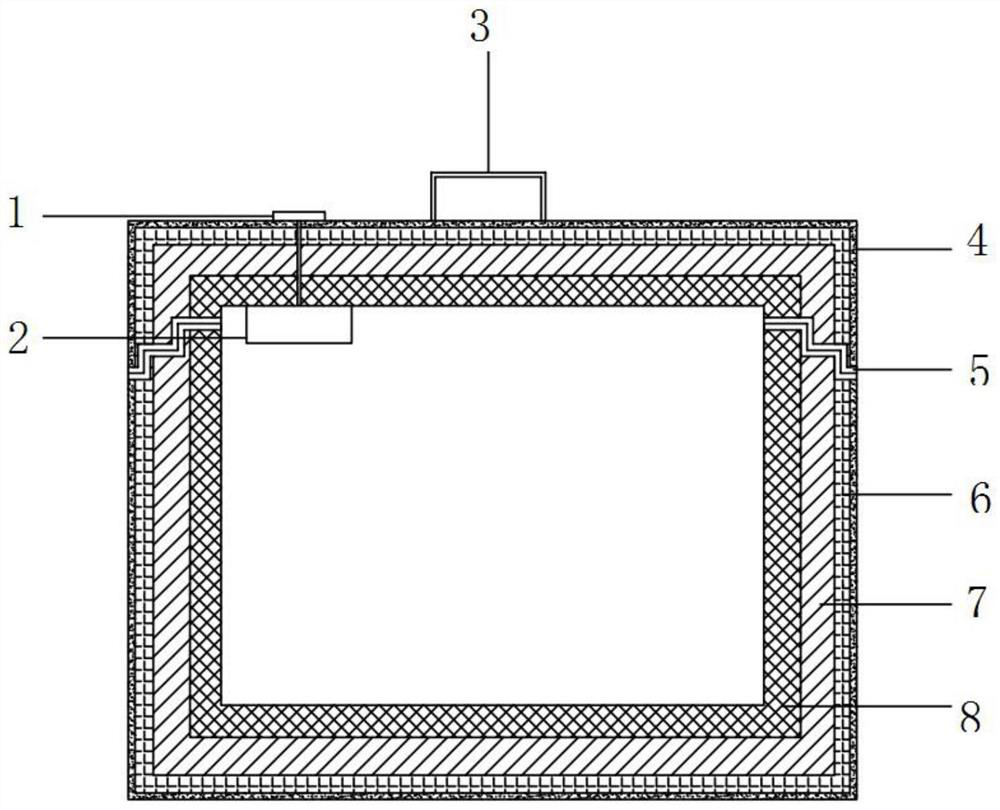

[0051] Such as figure 1 As shown in the fire-proof and explosion-proof box for batteries, the materials set from the inside to the outside of the box are fireproof material layer 6, adhesive layer, explosion-proof layer 7, adhesive layer, phase change insulation material layer 8, and outer box layer 4.

[0052] In this embodiment, the phase-change thermal insulation material is a hydrated salt composite phase-change thermal insulation material.

[0053] The explosion-proof layer 7 is made of foamed aluminum explosion-proof material.

[0054] The fireproof material layer 6 is made of nano-silicon floating bead board with a thickness of 3 cm and a fire resistance limit of 1 hour.

[0055] The material of the adhesive layer is polymerized silicone gel.

[0056] The outer casing layer 4 is fire-resistant and weather-resistant steel.

[0057] The 11 positions of the charging hole and the opening and closing of the box are equipped with flexible sealing materials that match the f...

Embodiment 2

[0059] Such as figure 1 As shown in the fire-proof and explosion-proof box for batteries, the materials set from the inside to the outside of the box are fireproof material layer 6, adhesive layer, explosion-proof layer 7, adhesive layer, phase change insulation material layer 8, and outer box layer 4.

[0060] In this embodiment, the phase change thermal insulation material is a fatty acid-fatty alcohol / expanded perlite composite phase change material.

[0061] The explosion-proof layer 7 is made of polyurethane foam aluminum composite material.

[0062] Fireproof material layer 6 selects nano-silicon floating bead plate for use. 3.5cm thick, fire resistance limit 1.5 hours.

[0063] The material of the adhesive layer is polymerized silicone gel.

[0064] The outer box body layer 4 is Q235 steel plate.

[0065] The 11 positions of the charging hole and the opening and closing of the box are equipped with flexible sealing materials that match the fire resistance limit of t...

Embodiment 3

[0067] Such as figure 1 As shown in the fire-proof and explosion-proof box for batteries, the materials set from the inside to the outside of the box are fireproof material layer 6, adhesive layer, explosion-proof layer 7, adhesive layer, phase change insulation material layer 8, and outer box layer 4.

[0068] In this embodiment, the phase change thermal insulation material is a fatty acid phase change material.

[0069] The explosion-proof layer 7 is made of foamed magnesium.

[0070] Fireproof material layer 6 selects rock wool for use. 4cm thick, the fire resistance limit is 2 hours.

[0071] The material of the adhesive layer is polymerized silicone gel.

[0072] The outer box body layer 4 is Q460 steel plate.

[0073] The 11 positions of the charging hole and the opening and closing of the box are equipped with flexible sealing materials that match the fire resistance limit of the box for sealing and sealing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com