Metal-ceramic composite lattice manufacturing method and metal-ceramic composite lattice structure

A composite lattice and manufacturing method technology, applied in the field of metal-ceramic composite lattice manufacturing and metal-ceramic composite lattice structure, can solve the problems of poor corrosion resistance, low high temperature strength, etc., and achieve enhanced service performance, high ratio Effects of strength and specific stiffness, good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

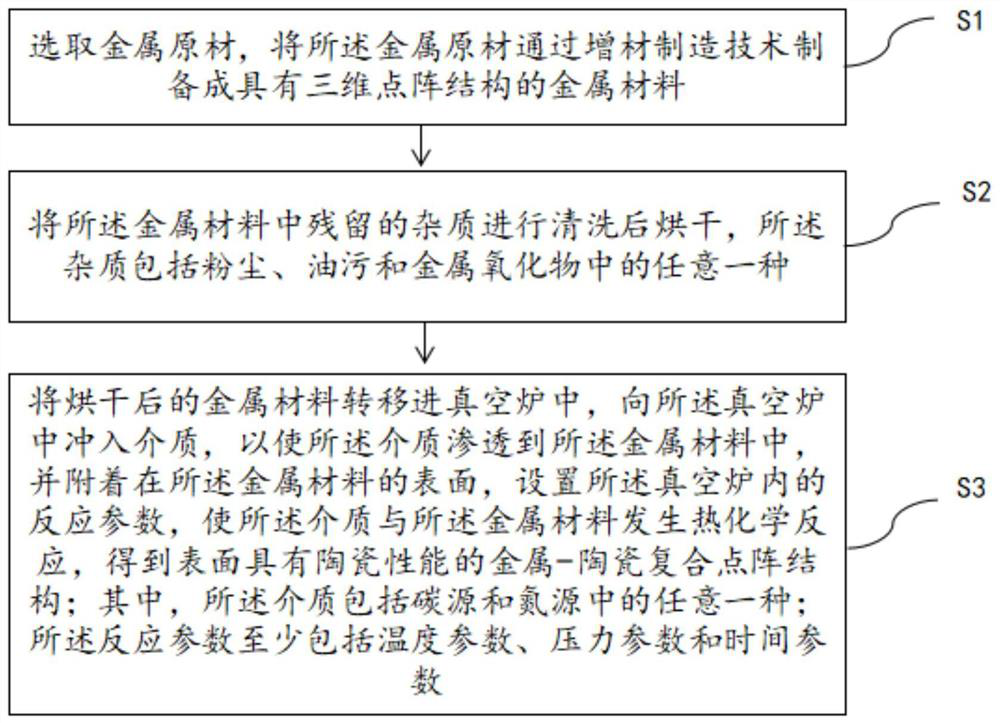

Method used

Image

Examples

Embodiment 1

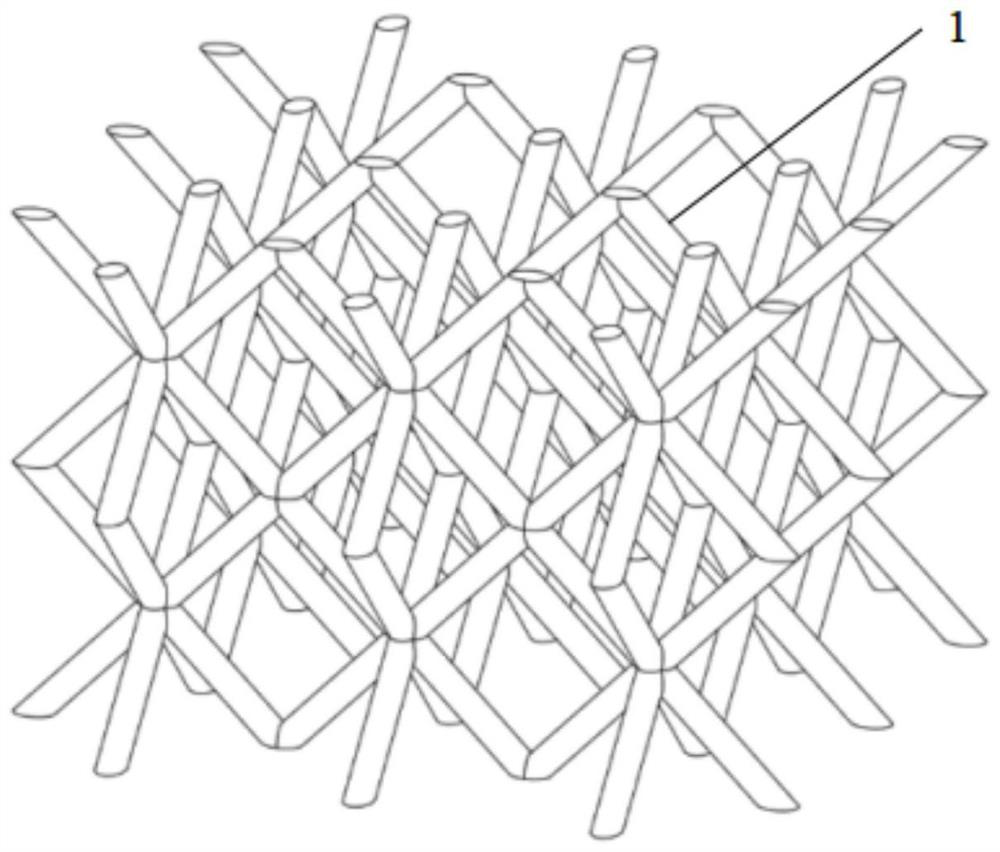

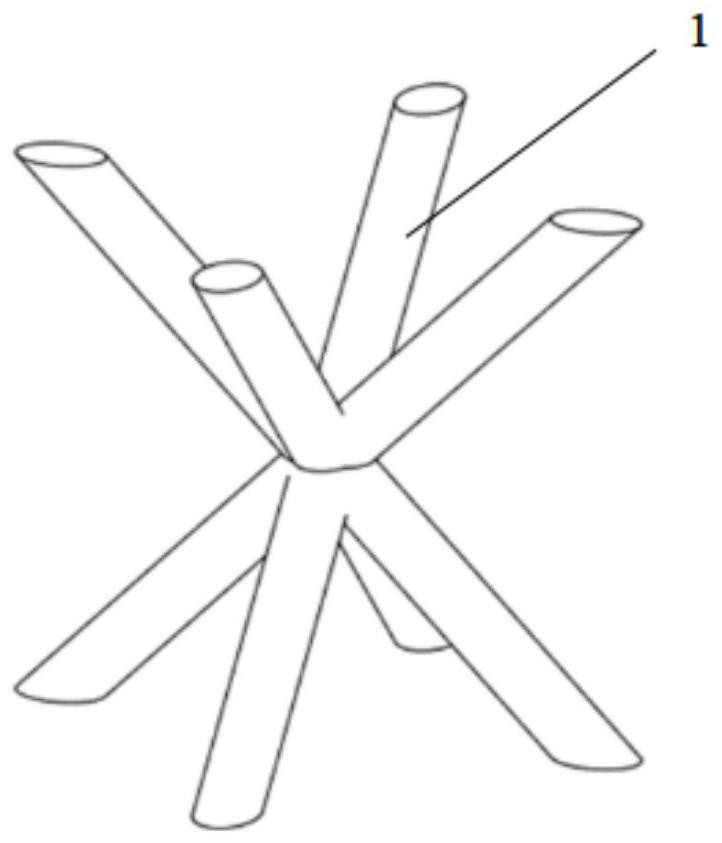

[0092] (1) Use SLM to print 316L stainless steel into a BCC (the body-centered cubic) lattice structure;

[0093] (2) Wash the BCC lattice structure sequentially with ultrasonic water for 5 minutes, acetone for 5 minutes, dilute hydrochloric acid for 5 minutes, ultrasonic water for 5 minutes, and dry;

[0094] (3) Put the dried BCC lattice structure into a vacuum furnace, use a vacuum system to evacuate the vacuum furnace to 7Pa, and then inject acetylene into the vacuum furnace in a pulse form with a partial pressure ratio of 1:3 and nitrogen, the furnace pressure is about 200Pa to stop;

[0095] (4) Use the control system to raise the temperature in the furnace to 910±10°C; hold for 7 hours;

[0096] (5) Utilize the cooling system to lower the temperature in the furnace to be room temperature;

[0097] (6) Utilize the control system to raise the temperature in the furnace to 650°C and keep it warm for 3 hours;

[0098] (7) Utilize the cooling system to lower the temperatu...

Embodiment 2

[0104] The difference from Example 1 is that the 316L stainless steel is printed into a BCCz (Z-direction enhanced-the body-centered cubic, Z-direction enhanced body-centered cube) lattice structure by using the selective laser melting technology SLM, and the metal-ceramic composite BCCz dots are obtained. array structure. The remaining operations and principles are consistent with Embodiment 1.

Embodiment 3

[0106] The difference from Example 1 is that the dried BCC lattice structure is put into a vacuum furnace, and the vacuum furnace is evacuated to 7Pa by using a vacuum system, and then simultaneously injected into the vacuum furnace with a partial pressure ratio of 1:3 to Inject ethane and nitrogen in the form of pulses, and stop at a furnace pressure of about 200 Pa to obtain a metal-ceramic composite BCC lattice structure. The remaining operations and principles are consistent with Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com