High-adaptability ceramic continuous offset printing ink and printing ink and application thereof

An offset printing ink and ceramic technology, applied in the field of ceramic glaze, to achieve the effect of precise color, high precision and clear edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

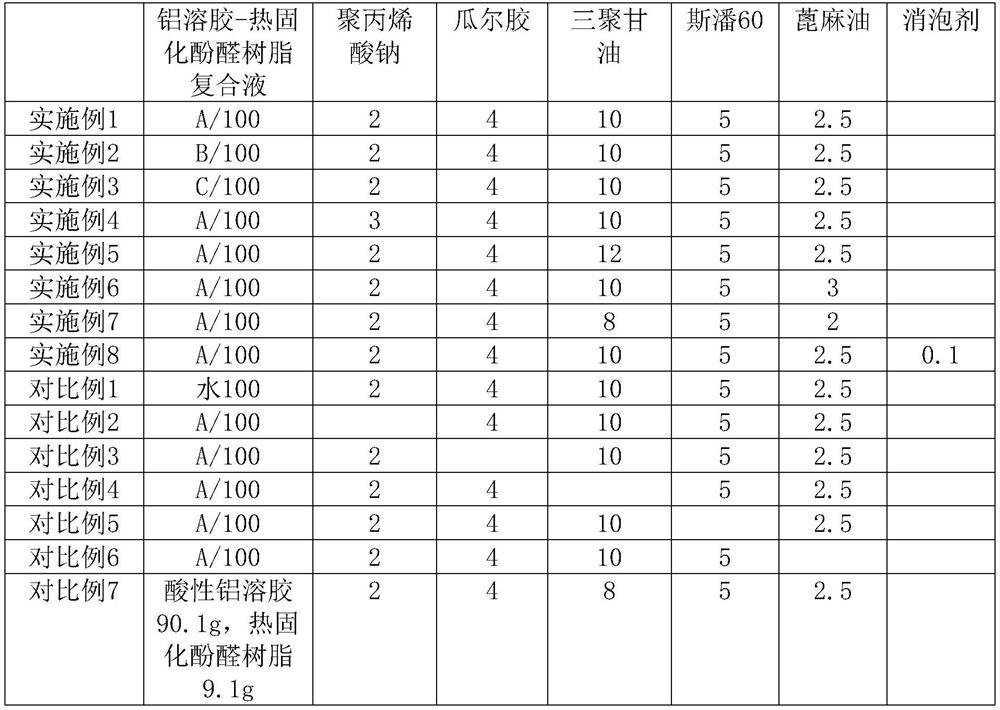

Examples

Embodiment 1

[0039] Prepare the ceramic continuous offset printing ink of the present embodiment as follows:

[0040] (1) Preparation of acidic aluminum sol: In a stirring reactor with reflux and continuous stirring, add water and raise the temperature to 85°C, add SB pseudoboehmite dry powder during stirring, control the temperature at 80°C and stir for 4h, add nitric acid to control the temperature at 80°C After reacting at ℃ for 8 hours, cool to room temperature, stop stirring, and age for 30 hours to obtain acidic silica sol; the ingredients are: water, SB pseudo-boehmite dry powder in a mass ratio of 100:6, SB pseudo-boehmite dry powder, nitric acid The amount ratio of substances is 100:10; the SB pseudoboehmite dry powder is PURAL SB, a product of German sasol company; the obtained acidic aluminum sol is translucent and milky white, and the light path can be seen clearly when irradiated by thin beams of light, pH3.9, average colloidal particle 9nm in diameter, stable and no detectabl...

Embodiment 2

[0046] Prepare the ceramic continuous offset printing ink of this example basically according to the method of Example 1, the difference is that when preparing the acidic aluminum sol in step (1), the ratio of the amount of SB pseudoboehmite dry powder to nitric acid is 100:8; the obtained acidic aluminum sol , translucent milky white, a clear light path can be seen when irradiated by thin beams of light, pH4.1, average colloidal particle diameter 10nm, stable and no detectable change in airtight storage at room temperature for 6 months; the aluminum sol-heat-cured phenolic resin composite solution B obtained in step (3) , translucent light brownish red, pH 8.0, a clear optical path can be seen when irradiated by thin beams of light, the average diameter of the detected colloidal particles is 10nm, and the viscosity is about 780mPa.s; it is stable and has no detectable changes after 3 months of sealed storage at room temperature.

Embodiment 3

[0048] Prepare the ceramic continuous offset printing ink of this embodiment basically according to the method of Example 1, the difference is that when preparing the heat-cured phenolic resin in step (2), the ingredients are based on the formaldehyde solution in terms of formaldehyde, phenol, and borax, and the ratio of the amount of substances is 2.0:1: 0.04; The obtained heat-cured phenolic resin is transparent light brownish red, with a viscosity of 1200mPa.s, stable and no detectable change in airtight storage at room temperature for 3 months; step (3) gained aluminum sol-thermally cured phenolic resin composite liquid C is translucent Light brown-red, pH8.1, a clear light path can be seen when irradiated by thin beams of light, the average diameter of the detected colloidal particles is 10nm, and the viscosity is about 730mPa.s; it is stable and has no detectable changes for 3 months in airtight storage at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com